Device and method for shortening phase changing time of brushless direct current motor

A brushless DC motor and DC voltage source technology is applied in the field of devices for shortening the commutation time of a brushless DC motor, and can solve the problems affecting the detection of rotor position signals, so as to shorten the commutation time, weaken the commutation torque ripple, and reduce the commutation time. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

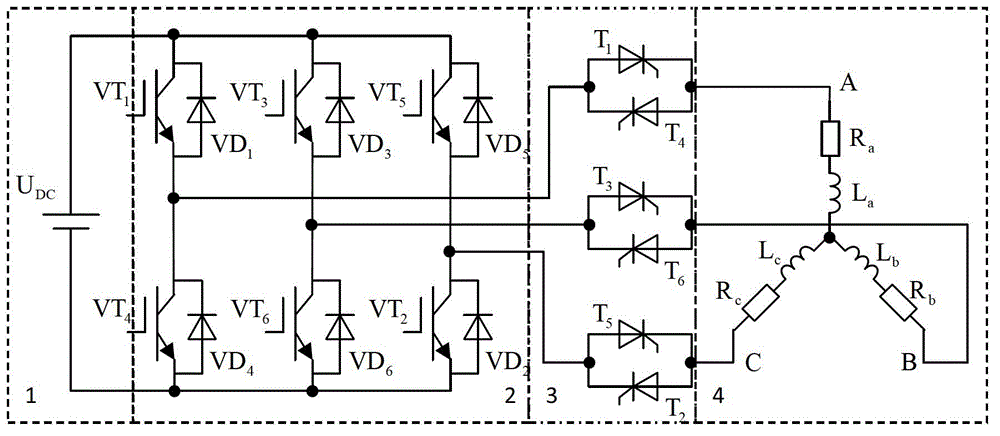

[0014] figure 1 Shown is a block diagram of the driving part of the brushless DC motor control system including the method of the present invention, which is composed of a brushless DC motor 4, a three-phase full-bridge inverter 2, a DC voltage source 1, and a thyristor circuit 3. Each bridge arm of the three-phase full-bridge inverter is composed of a power tube and a freewheeling diode connected in parallel, which are respectively the power tube VT 1 , VT 3 , VT 5 , VT 2 , VT 4 , VT 6 and freewheeling diode VD 1 , VD 3 , VD 5 , VD 2 , VD 4 , VD 6 ; T 1 , T 3 , T 5 , T 2 , T 4 , T 6 Respectively anti-parallel thyristor; R a , L a Respectively, the resistance and inductance of phase A, R b , L b Respectively, the resistance and inductance of phase B, R c , L c Respectively, the resistance and inductance of phase C.

[0015] The technical solution adopted in the present invention is: on the wires connecting the three-phase bridge inverter and the brushles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com