Welding material for ni-based heat-resistant alloy, and welded metal and welded joint each using same

A technology of heat-resistant alloys and welding materials, applied in welding/cutting media/materials, welding/welding/cutting items, welding media, etc., which can solve problems such as stress relaxation cracks and residual stress relaxation cracks that are not considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

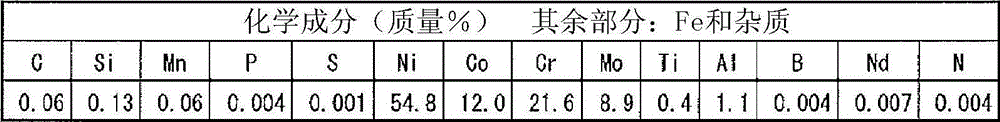

[0133] The ingot is melted and cast in the laboratory with the chemical composition shown in Table 1, and is made into a plate with a thickness of 12mm, a width of 50mm, and a length of 100mm through hot forging, hot rolling, heat treatment and mechanical processing. The plate is used as the plate for welding base material.

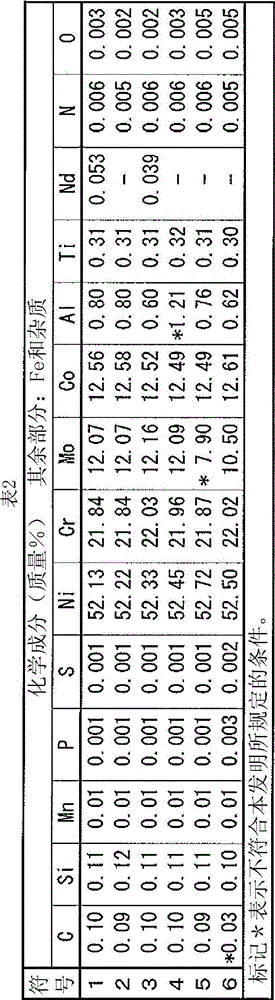

[0134] In addition, the ingots obtained by melting and casting the materials of symbols 1 to 6 having the chemical compositions shown in Table 2 were produced by hot forging, hot rolling, and mechanical processing to have an outer diameter of 1.2 mm and a length of 1000mm of welding material (welding wire).

[0135] Table 1

[0136] Table 1

[0137]

[0138] Table 2

[0139]

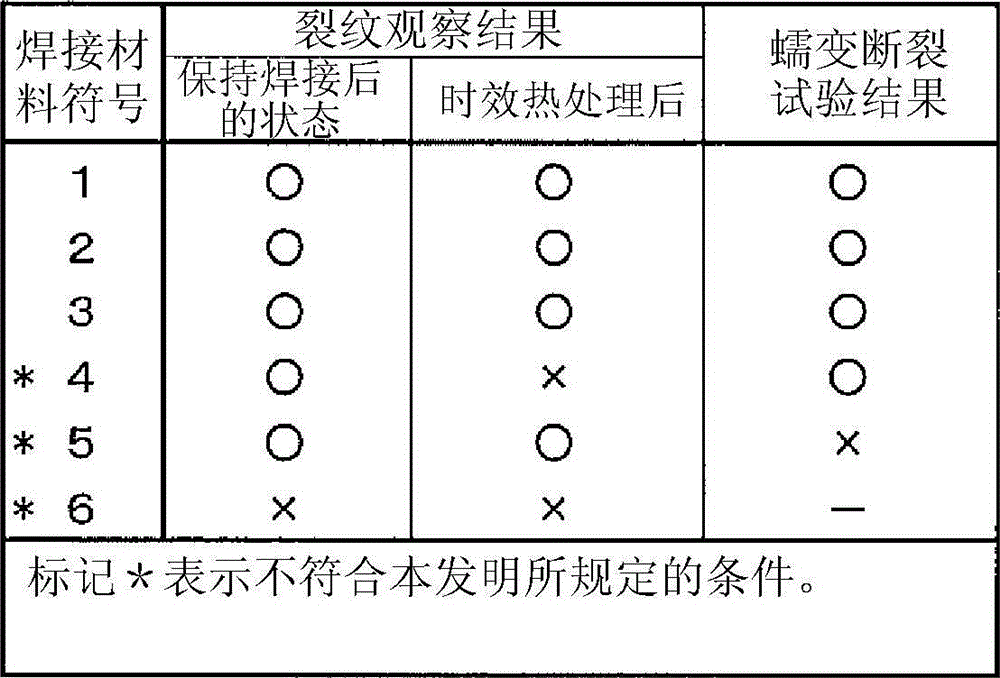

[0140] In the length direction of the above-mentioned plate for welding the base metal, a V-shaped groove with an angle of 30° and a thickness of the blunt edge of 1 mm is processed, and then "DNiCrFe-3" specified in JIS Z3224 (1999) is used as an electrode, Constraint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com