Ultra-fine grain high-nickel-chromium molybdenum infinitely chilled ductile cast iron and composite roll thereof

A technology of infinite chilled cast iron and ultra-fine grains, applied in the direction of rolling, metal rolling, metal rolling, etc., can solve the problems of insufficient heat crack resistance and other problems, and achieve the benefits of improving surface quality, rolling volume, and reducing The effect of rolling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

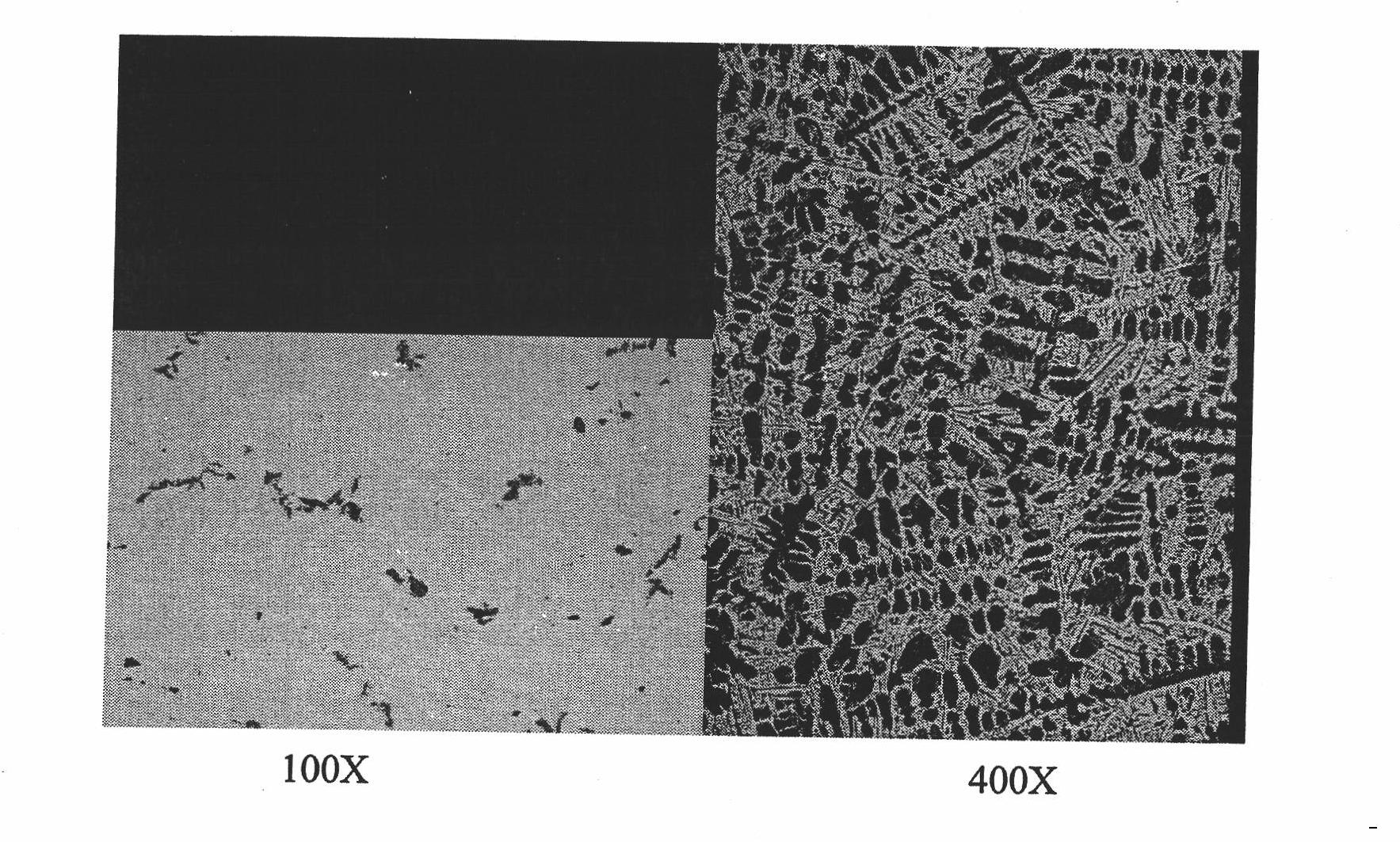

[0015] Example 1: Ultra-fine grain high nickel-chromium-molybdenum infinite chilled cast iron, adding 3% by weight (calculated as pure substance) of antimony to the molten iron composed of nickel-chromium-molybdenum infinite chilled cast iron GB / T1504-91.

Embodiment 2

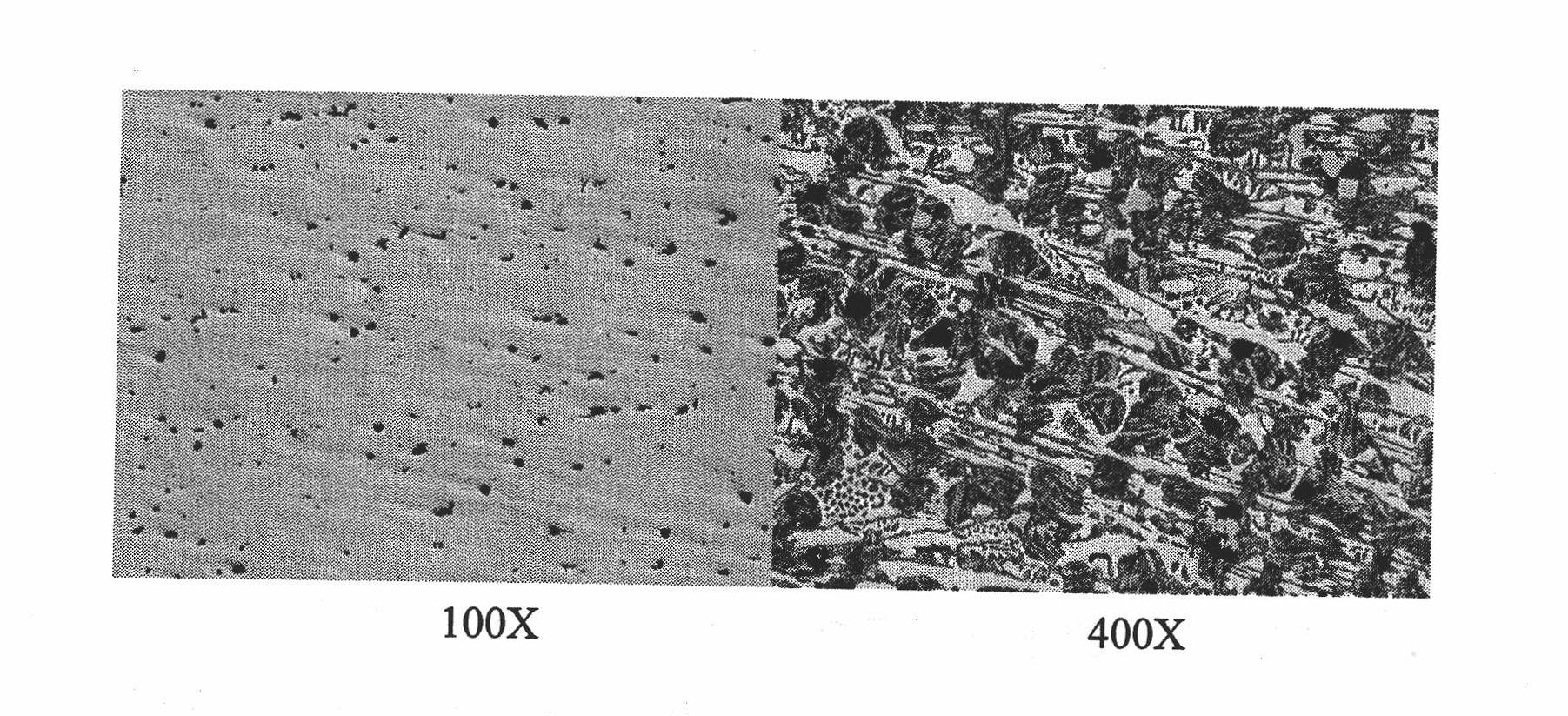

[0016] Embodiment 2: ultrafine-grained high nickel-chromium-molybdenum infinite chilled cast iron, in GB / T1504-91 nickel-chromium-molybdenum infinite chilled cast iron composition iron liquid, add the vanadium of 2% by weight (in terms of pure matter) and 0.5% by weight of Vanadium (as pure substance).

Embodiment 3

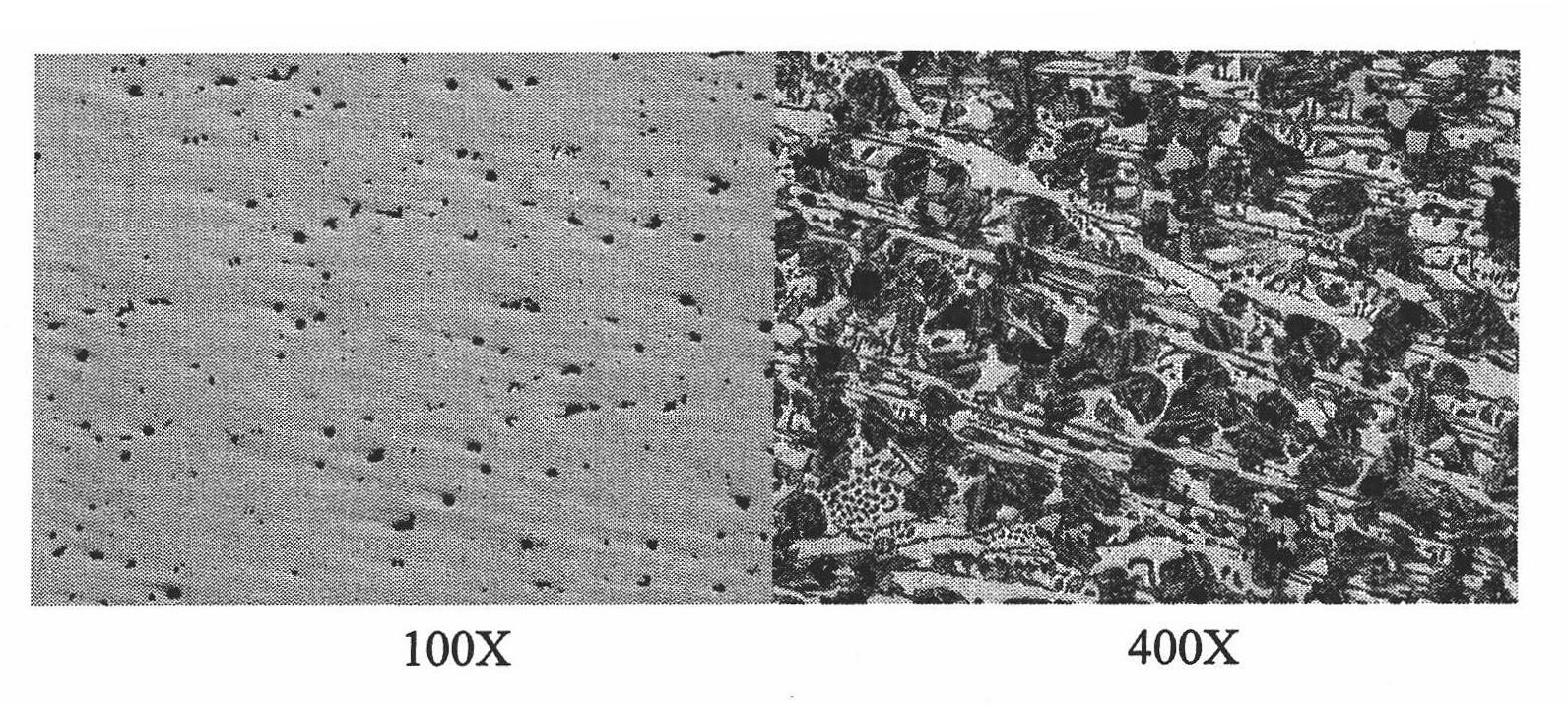

[0017] Embodiment 3: Referring to Example 2, the added weight of antimony is 1% (in pure matter), and the added weight of vanadium is 0.8% (in pure matter).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com