Quick thermal-curing coating baking line

A thermal curing and baking line technology, which is applied in the direction of surface coating liquid devices, coatings, pretreatment surfaces, etc., can solve the problem that the paint film cannot be cured quickly, reduce the temperature, reduce the temperature rise, Insulation effect of heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

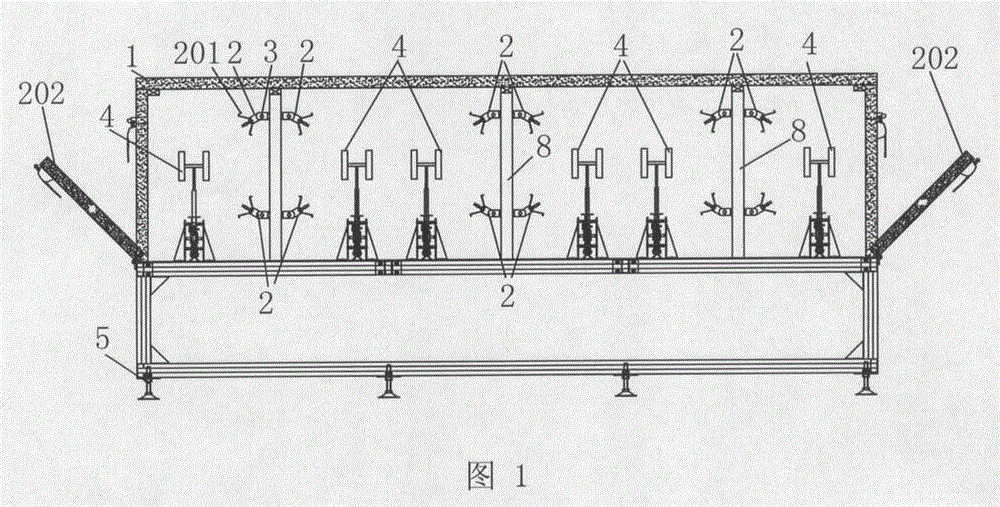

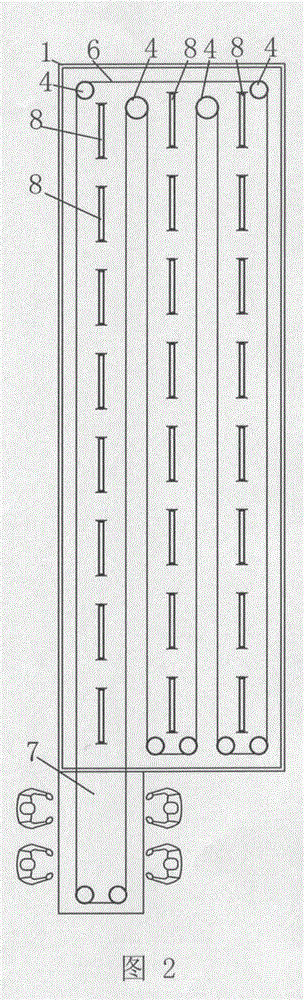

[0014] refer to figure 1 , figure 2 As shown, a rapid thermal curing coating baking line is designed, and a baking oven body 1 is provided. One end of the oven body 1 is provided with a product inlet, an outlet, and a workbench 7. Inside the oven body 7 At least three rows of high-efficiency curing lamps 2 are arranged at intervals, and a self-rotating mechanism 2 is provided at the front end of the three rows of high-efficiency curing lamps 2, and a self-rotating mechanism 2 is worn on the self-rotating mechanism 2 to bypass the three rows of high-efficiency curing lamps. The endless chain 6 between the lamps 2 and between the workbench 7.

[0015] In the above-mentioned rapid thermal curing coating baking line, three rows of high-efficiency curing lamps 2 are arranged in the baking oven body 1, and the arrangement of the three rows of high-efficiency curing lamps 2 is as follows: in the middle of the oven body 1 There are three rows of brackets, and each row of brackets i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com