Automatic dust removal and spray system for household ceramic blank

An automatic dedusting and spraying system technology, which is applied in the field of dedusting and wetting processes on the blank surface, can solve the problems of high cost investment, not meeting the actual needs of ceramic production, and the inability to guarantee the surface moisture of the object, so as to save labor costs, Improve production efficiency, good spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

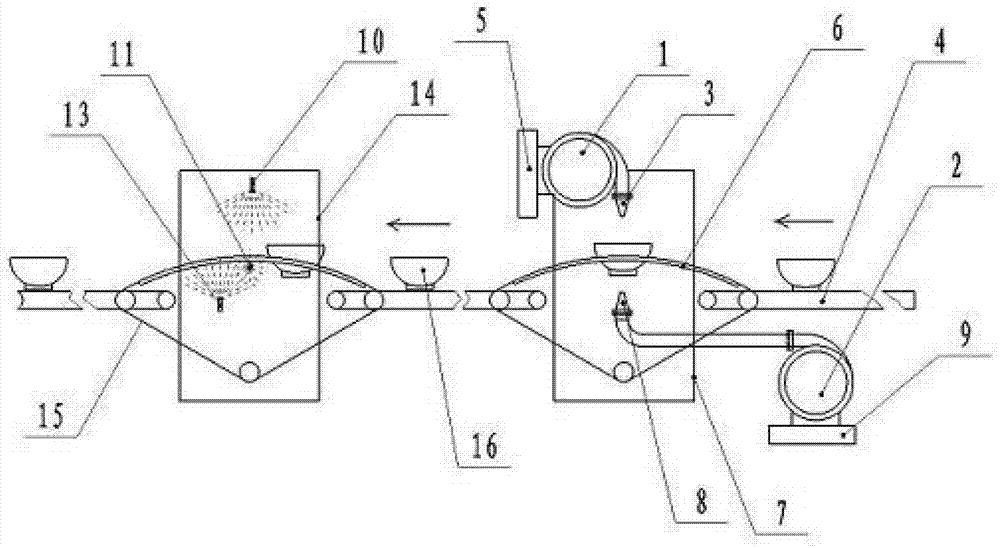

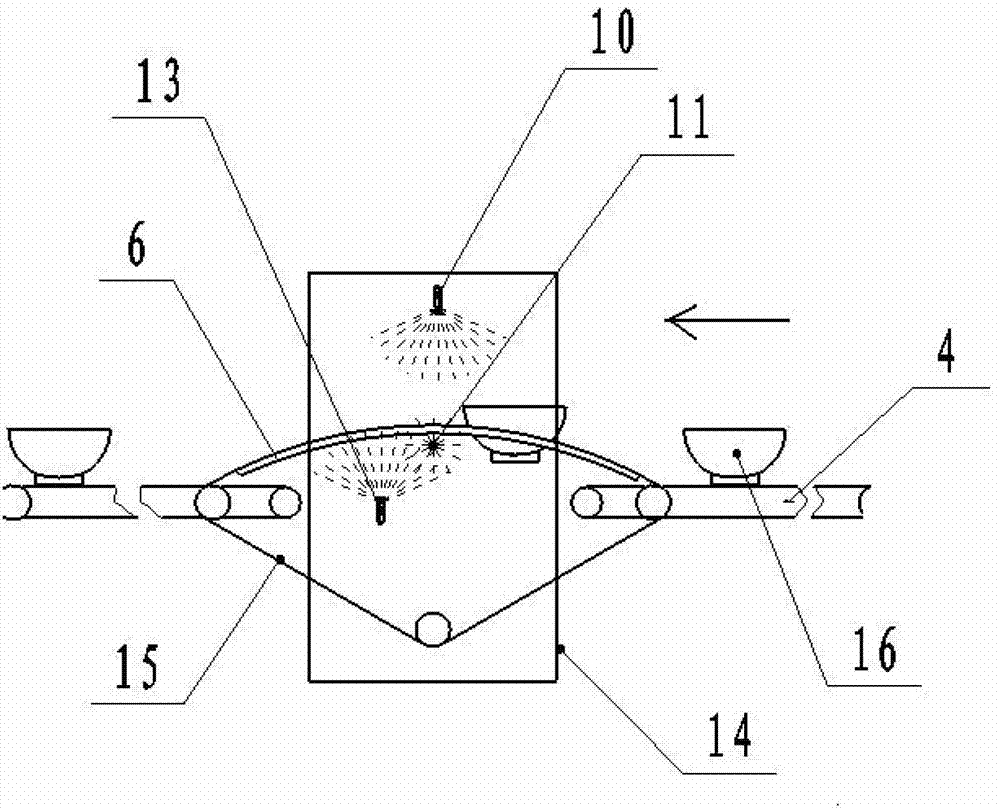

[0018] Such as figure 1 As shown, the dust removal device and the spraying device are installed on the production line according to the order of the production process and the blank conveyor belt is used as the reference, including the water storage and supply device, the atomization chamber 14, and the blank conveyor belt 4 . The automatic dedusting device and automatic spraying device of the system are equipped with a transmission belt transition bridge that lifts the billet overhead, the two ends of the transmission belt transition bridge connect the blank conveyor belt 4, the bracket 6 of the transmission belt transition bridge supports the transition bridge conveyor belt 15, and the transition bridge conveyor belt It is driven by the rollers at a constant speed with the billet conveyor belt.

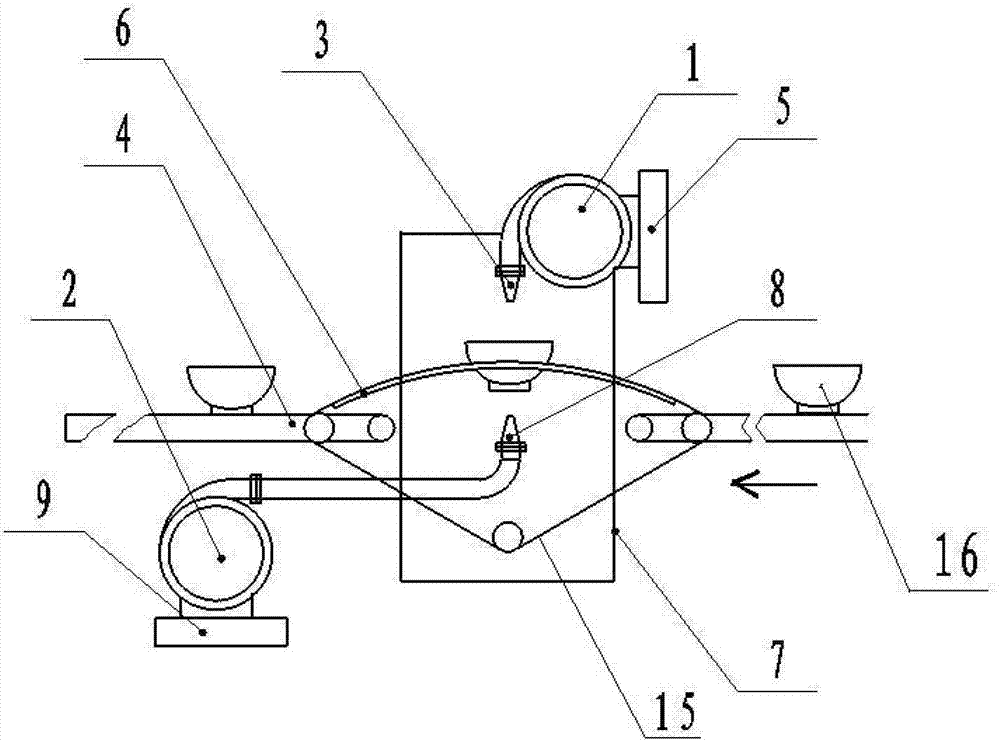

[0019] Such as figure 2 As shown, the automatic dust removal device includes an upper medium pressure fan 1, a lower medium pressure fan 2, an upper air nozzle 3, a billet conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com