Hydraulic power assisted diverter of circulating ball with floatable piston

A technology of hydraulic power steering and recirculating ball, applied in the direction of fluid steering mechanism, etc., can solve the problems of stuck steering gear, poor flow ability of piston steel ball, poor coaxiality of screw screw raceway and piston screw raceway, etc. To achieve the effect of eliminating steering hairpins, good driving feeling, and simple tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Describe the present invention in detail below in conjunction with accompanying drawing:

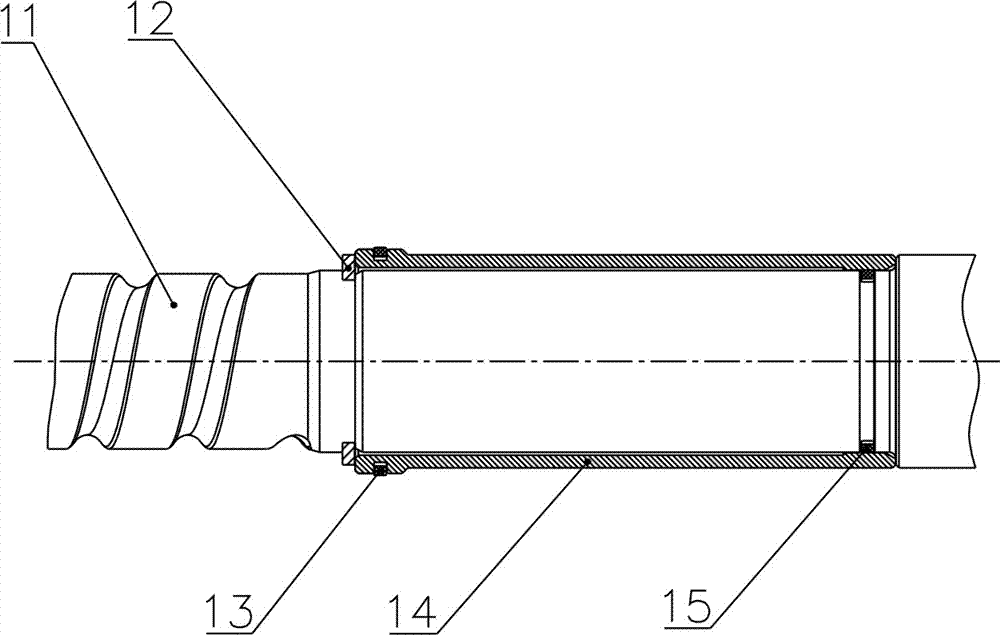

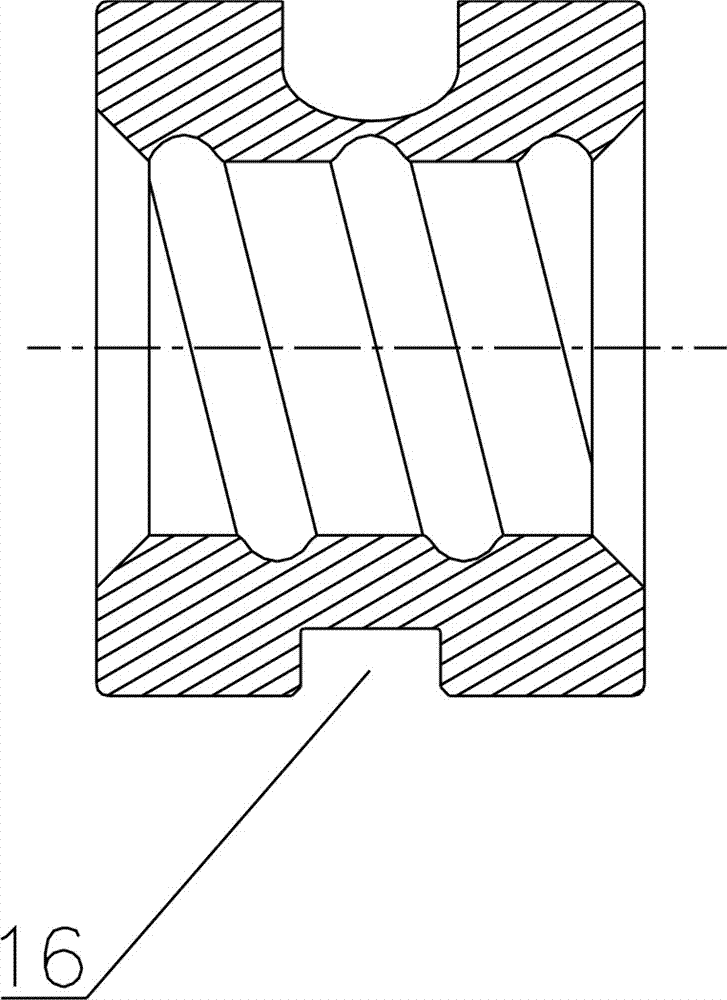

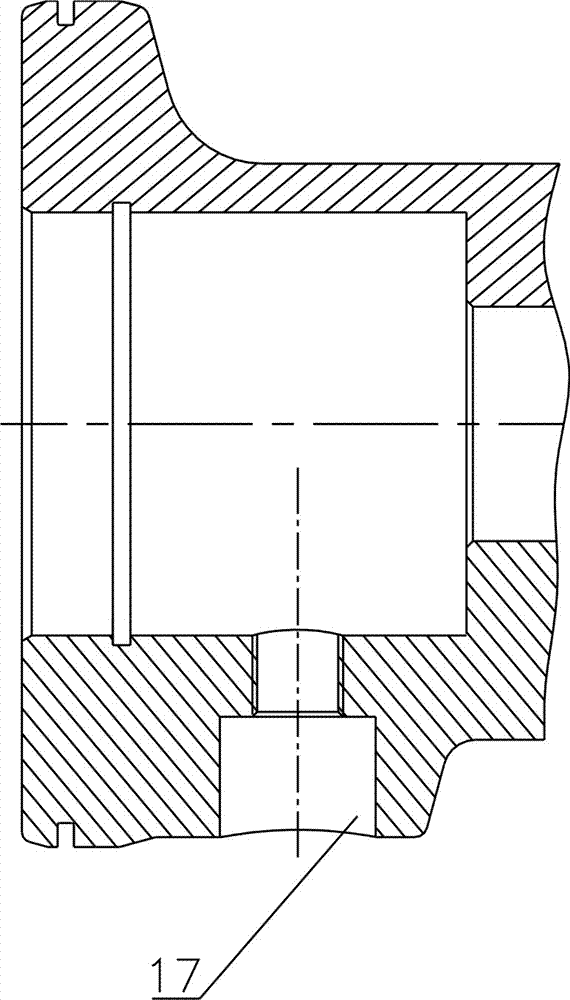

[0017] As shown in the figure, a recirculating ball hydraulic power steering device with a floating piston of the present invention mainly includes a valve assembly 1 , a rack piston 2 , a housing 18 and an output shaft 19 . The valve assembly 1 is provided with a screw rod 11, and the rack piston 2 is sleeved on the screw rod 11. A sealing sliding sleeve 14 is provided between the end of the rack piston 2 close to the valve assembly 1 and the screw rod 11 , and a nut 4 is provided between the other end of the rack piston 2 and the screw rod 11 . Such as figure 2 As shown, a sealing ring 15 is provided between the screw rod 11 and the sealing sliding sleeve 14 for sealing, and a sealing ring 13 is provided between the sealing sliding sleeve 14 and the rack piston 2 for sealing. A C-shaped snap ring 12 is also provided at the end of the sealing sliding sleeve 14 . Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com