Patching material for carbonless ladle working lining

A carbon-free steel ladle and repair material technology, applied in the field of unshaped refractory materials, can solve the problems of poor smearing performance, poor slag erosion resistance, weak bonding performance, etc., and achieve easy smearing, good bonding performance, and effective good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

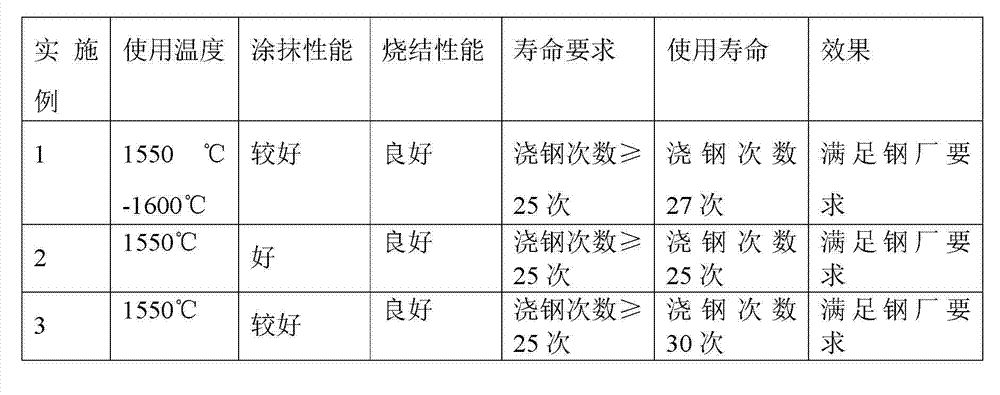

Examples

Embodiment 1

[0028] A repairing material for working lining of a ladle, the content of each component is calculated in parts by weight: Al 2 o 3 75kg of super-grade bauxite with a content ≥ 85%, the composition is: 15kg for 5mm ≥ particle size > 3mm, 25Kg for 3mm ≥ particle size > 1mm, 22Kg for 1mm ≥ particle size > 0.088mm, 13Kg for particle size ≤ 0.088mm; Fused magnesia with MgO content ≥ 95% 13kg, composition: 9Kg for 1mm ≥ particle size > 0.088mm, 4Kg for particle size ≤ 0.088mm; Guangxi white mud 3.5kg; dextrin 0.5kg; silica powder 3 ㎏; Aluminum oxide powder 5㎏.

[0029] Preparation Process:

[0030] Weigh the above raw materials according to the formula, add them into the forced mixer and stir, first add aggregate, then add fine powder, micro powder and binder and stir for 3 to 5 minutes, and the material can be discharged after stirring evenly.

Embodiment 2

[0032] A repairing material for working lining of a ladle, the content of each component is calculated in parts by weight: Al 2 o 3 78 kg of corundum with a content ≥ 85%, the composition is: 22 kg for 5 mm ≥ particle size > 3 mm, 20 kg for 3 mm ≥ particle size > 1 mm, 22 kg for 1 mm ≥ particle size > 0.088 mm, 14 kg for particle size ≤ 0.088 mm; MgO 10kg of high-purity magnesia with content ≥ 95%, composition: 7Kg for 1mm ≥ particle size > 0.088mm, 3Kg for particle size ≤ 0.088mm; 4kg of Guangxi white clay; 3kg of silica powder; 5kg of alumina powder.

[0033] Preparation Process:

[0034] Weigh the above raw materials according to the formula, add them into the forced mixer and stir, first add aggregate, then add fine powder, micro powder and binder and stir for 3 to 5 minutes, and the material can be discharged after stirring evenly.

Embodiment 3

[0036] A repairing material for working lining of a ladle, the content of each component is calculated in parts by weight: Al 2 o 3 Corundum content ≥ 85% 85kg, the composition is: 5mm ≥ particle size > 3mm is 17kg, 3mm ≥ particle size > 1mm is 22Kg, 1mm ≥ particle size > 0.088mm is 24Kg, particle size ≤ 0.088mm is 22Kg; MgO content ≥95% mid-range magnesia 5kg, composition: 4Kg for 1mm≥particle size>0.088mm, 1Kg for particle size≤0.088mm; 2.5kg of Guangxi white mud; 0.5kg of carboxymethyl salt; 4kg of silica powder ; Aluminum oxide powder 3 kg.

[0037] Preparation Process:

[0038] Weigh the above raw materials according to the formula, add them into the forced mixer and stir, first add aggregate, then add fine powder, micro powder and binder and stir for 3 to 5 minutes, and the material can be discharged after stirring evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com