High-softening-point polyamide resin and its preparation method

A technology of polyamide resin and high softening point, which is applied in the field of high softening point polyamide resin and its preparation, and can solve the problems of unrealized adhesion and insufficient softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. Feeding of dimer acid: open the high-purity nitrogen valve and repeatedly flush to ensure that the air content in the kettle does not exceed 5%, accurately weigh 6000 kg of dimer acid in the metering tank, and send it into the reaction kettle with a stainless steel gear pump or vacuum , The delivery temperature is 50-60°C. Weigh 100 kg of glacial acetic acid according to the required softening point and send it into the reactor. Close the feed valve, open the hot oil valve to start heating up.

[0016] 2. Feeding of ethylenediamine and hexamethylenediamine: According to the required softening point, weigh 500Kg of ethylenediamine and 150Kg of hexamethylenediamine and add them to the amine tank for mixing and set aside.

[0017] 3. When the material temperature rises to 130-140°C, start to drop the mixture of ethylenediamine and hexamethylenediamine. Control the filling speed at 5-6 kg / min. Observe the reaction phenomenon in the kettle through the sight glass, keep...

Embodiment 2

[0023] 1. Feeding of dimer acid: open the high-purity nitrogen valve and repeatedly flush to ensure that the air content in the kettle does not exceed 5%, accurately weigh 6000 kg of dimer acid in the metering tank, and send it into the reaction kettle with a stainless steel gear pump or vacuum , The delivery temperature is 50-60°C. Weigh 300 kg of glacial acetic acid according to the required softening point and send it into the reactor. Close the feed valve, open the hot oil valve to start heating up.

[0024] 2. Feeding of ethylenediamine and hexamethylenediamine: According to the required softening point, weigh 600Kg of ethylenediamine and 150Kg of hexamethylenediamine and add them to the amine tank for mixing and set aside.

[0025] 3. After that, the steps are the same as in Example 1.

Embodiment 3

[0027] 1. Feeding of dimer acid: open the high-purity nitrogen valve and repeatedly flush to ensure that the air content in the kettle does not exceed 5%, accurately weigh 6000 kg of dimer acid in the metering tank, and send it into the reaction kettle with a stainless steel gear pump or vacuum , The delivery temperature is 50-60°C. Weigh 500 kg of glacial acetic acid according to the required softening point and send it into the reactor. Close the feed valve, open the hot oil valve to start heating up.

[0028] 2. Feeding of ethylenediamine and hexamethylenediamine: According to the required softening point, weigh 700Kg of ethylenediamine and 150Kg of hexamethylenediamine and add them to the amine tank for mixing and set aside.

[0029] 3. After that, the steps are the same as in Example 1.

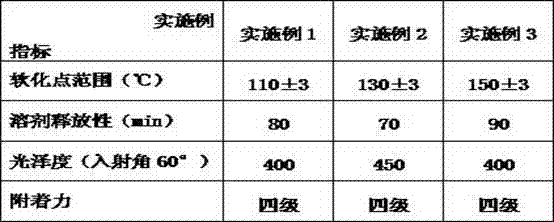

[0030] The indicators of each embodiment are shown in Table 1:

[0031] Table I:

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com