Technological method for extracting natural cinnamon oil

A technology of extraction process and process method, which is applied in the directions of fat oil/fat production and fat production, can solve the problems of low output rate of cinnamon oil and high production cost, and achieve the effects of improving condensation efficiency, improving efficiency and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing example, structure of the present invention is described in further detail:

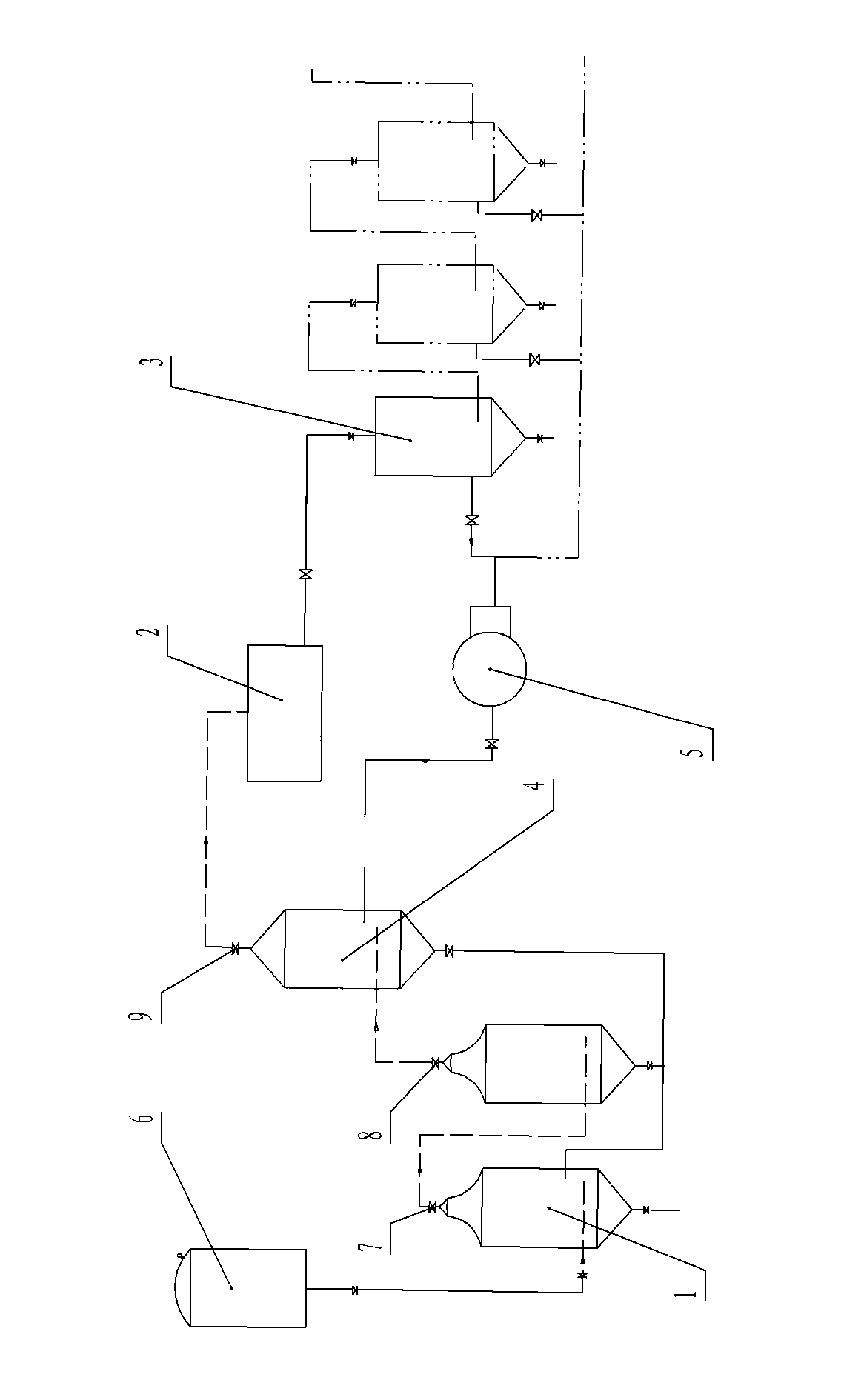

[0027] according to figure 1 The schematic diagram of the technological process adopts the natural cinnamon oil extraction equipment according to the following steps and methods:

[0028] (1) Put the cinnamon sticks and leaf cut sections into two stills 1, spray the water vapor in the boiler 6 into the bottom of the first still 1 through the steam pipe, and keep the temperature in the first still 1 as 100 ℃, pressure 0.05~0.08MP water vapor steams the cinnamon oil in the cinnamon sticks and cinnamon leaves in the kettle to form a mixed steam, and the mixed steam enters the second still 1 through the top valve 7 of the first still 1 Keep the temperature in the second still 1 at 100°C and the pressure at 0.05-0.08MP, and the cinnamon oil in the cinnamon sticks and cinnamon leaves in the second still 1 is also evaporated together, and the mixed stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com