Large-grid non-mold molded welding metal curtain wall and forming process thereof

A technology of moldless forming and welding metal, applied in metal processing equipment, walls, building components, etc., can solve the problems of easy springback, difficult mass production, difficult forming of metal sheet curtain walls, etc., and achieve the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

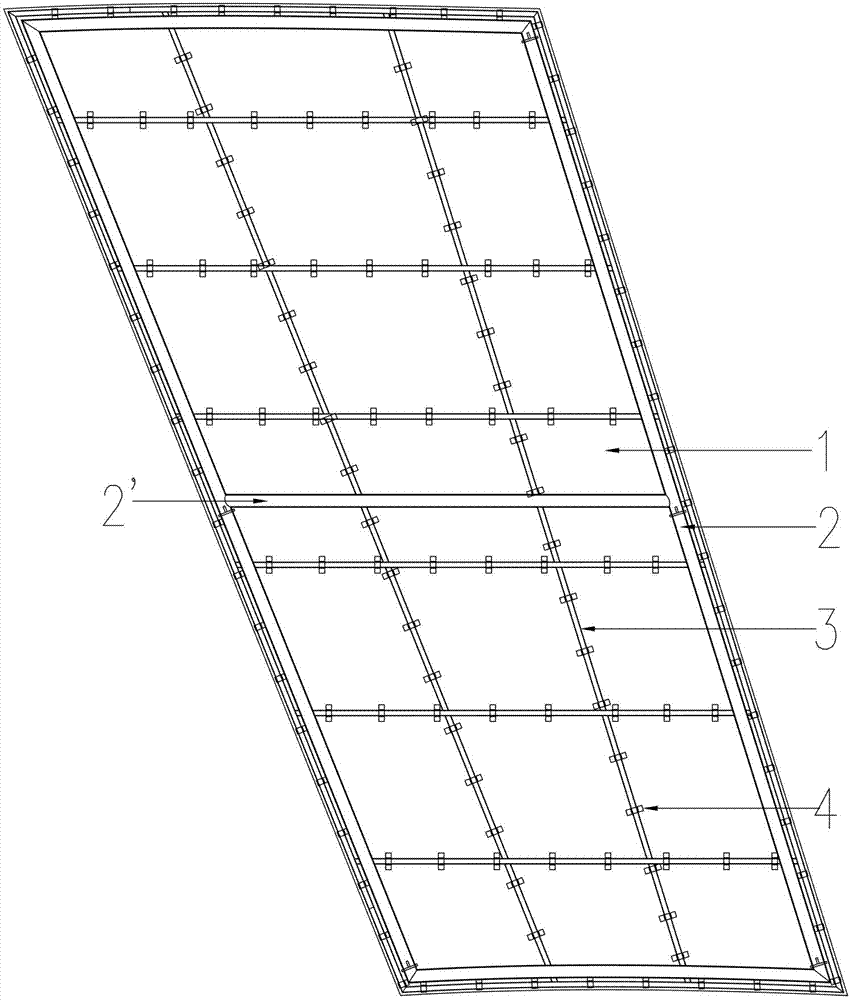

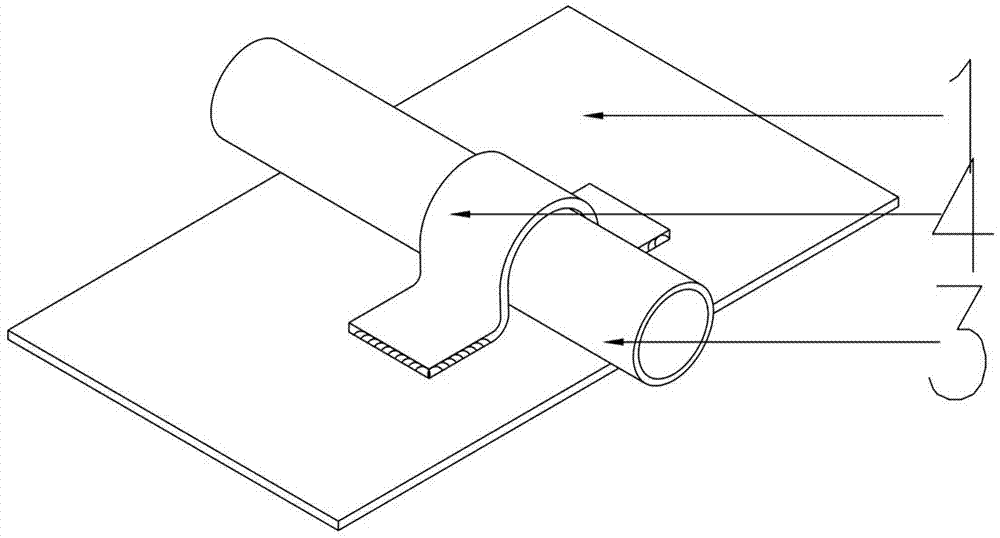

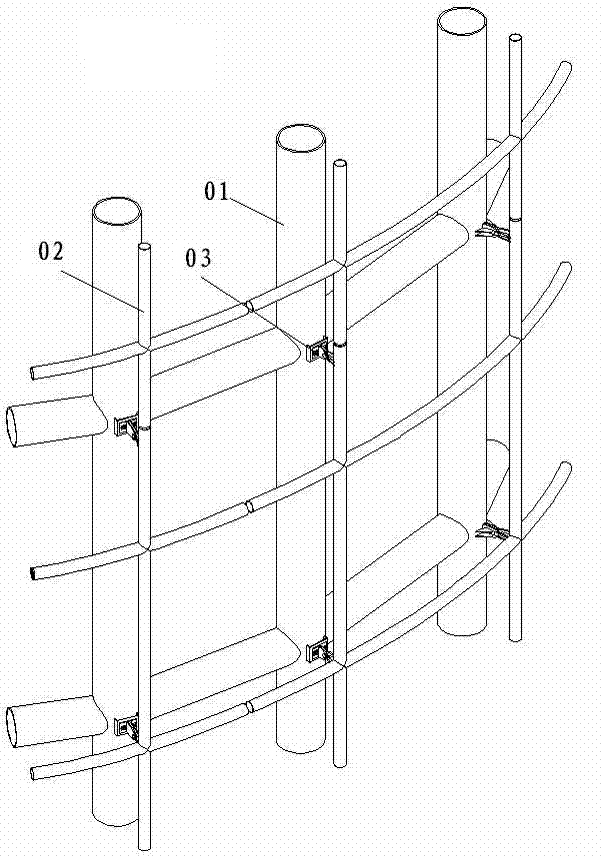

[0119] In this example, the metal plate is a 2mm thick stainless steel plate, and the size of each metal plate unit is 7m×3m (such as figure 1 As shown), the edge main pipe is the stiffener 2 is φ70×4, the secondary pipe is the stiffener wire 3 is φ30×2, and the distance between the stiffeners is 700mm×700mm.

[0120] The temperature change values of the steel structure in this example are as follows: the temperature rises and changes by 30°C; the temperature drops by 35°C.

[0121] The calculation process is as follows:

[0122] For the convenience of calculation, we consider that the steel structure is very rigid (this is relatively safe for the results), that is, the boundary condition of the plate is very rigid, and the temperature stress of the plate is calculated under this boundary condition. If the temperature stress of this condition meets the requirements, then The overall temperature stress also meets the requirements, because the boundary conditions of the actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com