A Secondary Air Arrangement Device for Garbage Incinerator

A waste incinerator and secondary air technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems affecting the stiffness of the secondary air jet, the decrease of the secondary air injection wind speed, the optimization of unfavorable air flow organization and the adjustment of combustion, etc. problems, achieve the effects of strengthening mixing and residence time, increasing combustion rate, and expanding fuel adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

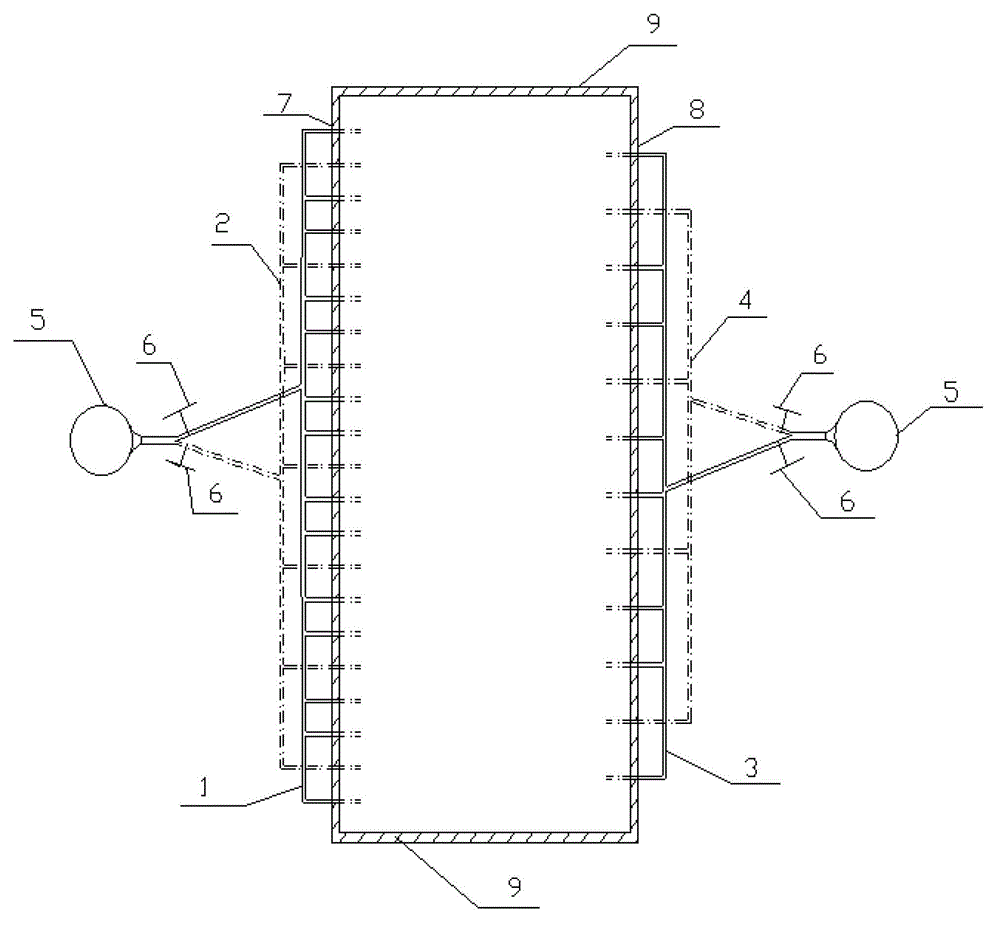

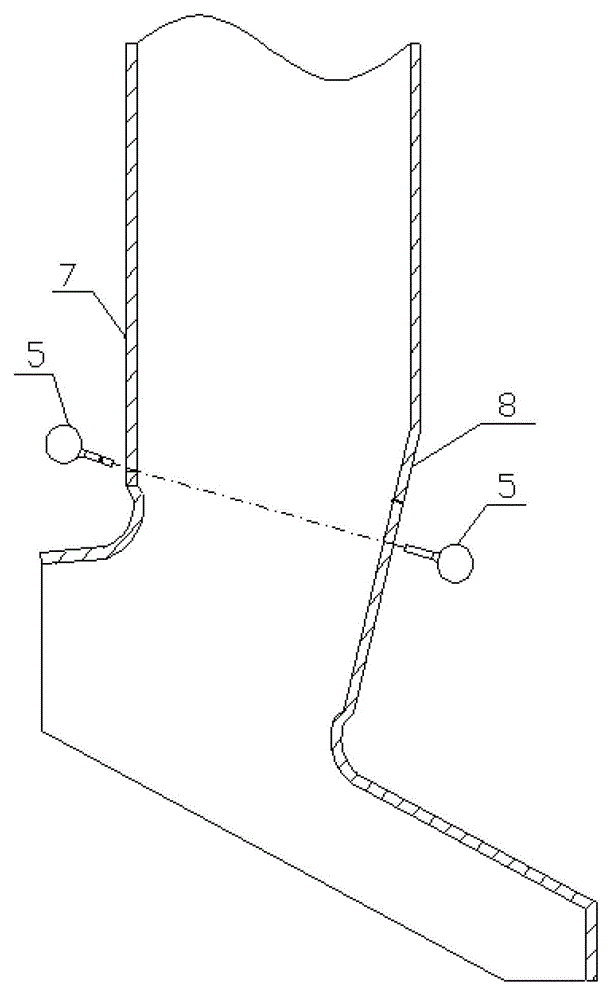

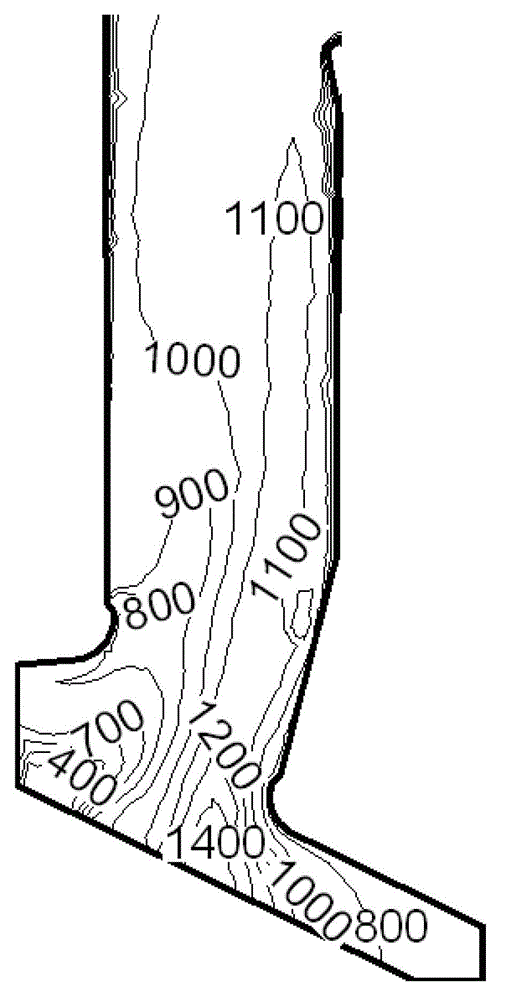

[0024] Such as figure 1 , 2 shown. The secondary air layout device of the garbage incinerator of the present invention includes a secondary air pipe 5, a secondary air door 6, a front wall 7, a rear wall 8, a side wall 9, a first group of secondary air nozzles 1 on the front wall, and a second air nozzle on the front wall. Two groups of secondary air nozzles 2, the first group of secondary air nozzles 3 on the rear wall, and the second group of secondary air nozzles 4 on the rear wall are characterized in that: the first group of secondary air nozzles 1 on the front wall and the second group of secondary air nozzles on the front wall The arrangement position of the two groups of secondary air nozzles 2 is 0.61m~1m away from the entrance of the first flue; the first group of secondary air nozzles 1 on the front wall and the second group of secondary air nozzles 2 on the front wall are on the same plane, and The angle between the injection angle and the inclined surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com