Flat-panel solar heat collector

A flat-panel solar energy and heat collector technology, applied in the field of solar energy, can solve the problems of low emission function and inability to take into account high absorption, etc., and achieve the effects of reducing heat loss coefficient, preventing conduction and radiation loss, and reducing radiation loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: The structure of the flat solar heat collector with an empty firing temperature in the range of low temperature solar heat utilization

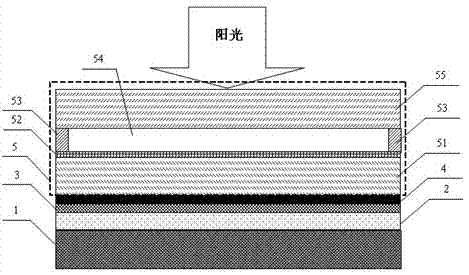

[0052] Such as figure 1 As shown, the structure of the flat solar heat collector described in this embodiment is composed of a heat insulation layer 1, a working medium 2, a metal substrate 3, an absorption film 4 and a low-radiation module 5 in sequence from the bottom layer to the top layer. The heat insulation layer 1 is located at the bottom of the collector; its upper layer is covered with a copper medium tube or medium cavity containing the working medium 2, and the medium tube or medium cavity is arranged and welded on the reverse side of the metal substrate 3; the absorption film 4 is deposited On the front side of the metal substrate 3 , the low-radiation module 5 covers the absorbing film 4 .

[0053] Wherein the low-emissivity module 5 consists of coated glass 51, a low-emissivity film 52 deposited on 51, a...

Embodiment 2

[0065] Embodiment 2: The structure of the flat solar heat collector with an empty firing temperature in the range of medium temperature solar heat utilization

[0066] The structure of the flat solar heat collector described in this embodiment consists of a heat insulation layer 1 , a working medium 2 , a metal substrate 3 , an absorption film 4 and a low-radiation module 5 from the bottom layer to the top layer. The heat insulation layer 1 is located at the bottom of the collector; its upper layer is covered with a copper medium tube or medium cavity containing the working medium 2, and the medium tube or medium cavity is arranged and welded on the reverse side of the metal substrate 3; the absorption film 4 is deposited On the front side of the metal substrate 3 , the low-radiation module 5 covers the absorbing film 4 .

[0067] Wherein the low-emissivity module 5 consists of coated glass 51, a low-emissivity film 52 deposited on 51, a hollow layer 54 above 52, a sealing s...

Embodiment 3

[0079] Embodiment 3: The structure of the flat solar collector with an empty firing temperature in the range of medium temperature solar heat utilization

[0080] The structure of the flat solar heat collector described in this embodiment consists of a heat insulation layer 1 , a working medium 2 , a metal substrate 3 , an absorption film 4 and a low-radiation module 5 from the bottom layer to the top layer. The heat insulation layer 1 is located at the bottom of the collector; its upper layer is covered with a copper medium tube or medium cavity containing the working medium 2, and the medium tube or medium cavity is arranged and welded on the reverse side of the metal substrate 3; the absorption film 4 is deposited On the front side of the metal substrate 3 , the low-radiation module 5 covers the absorbing film 4 .

[0081] Wherein the low-emissivity module 5 consists of coated glass 51, a low-emissivity film 52 deposited on 51, a hollow layer 54 above 52, a sealing strip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com