Ethylene glycol coolant circulating system

A technology of refrigerant circulation system and ethylene glycol, which is applied in the field of circulation system, can solve problems such as blockage, corrosion of the circulation system, and aging of the circulation system, and achieve the effects of reducing production costs, avoiding frequent replacement, and ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

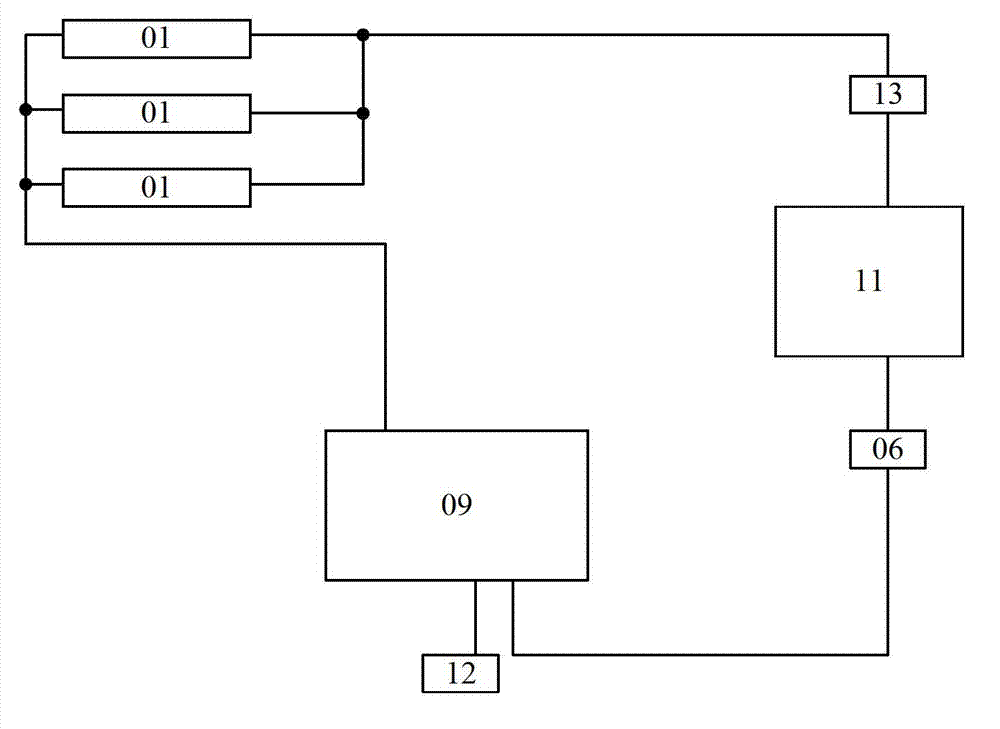

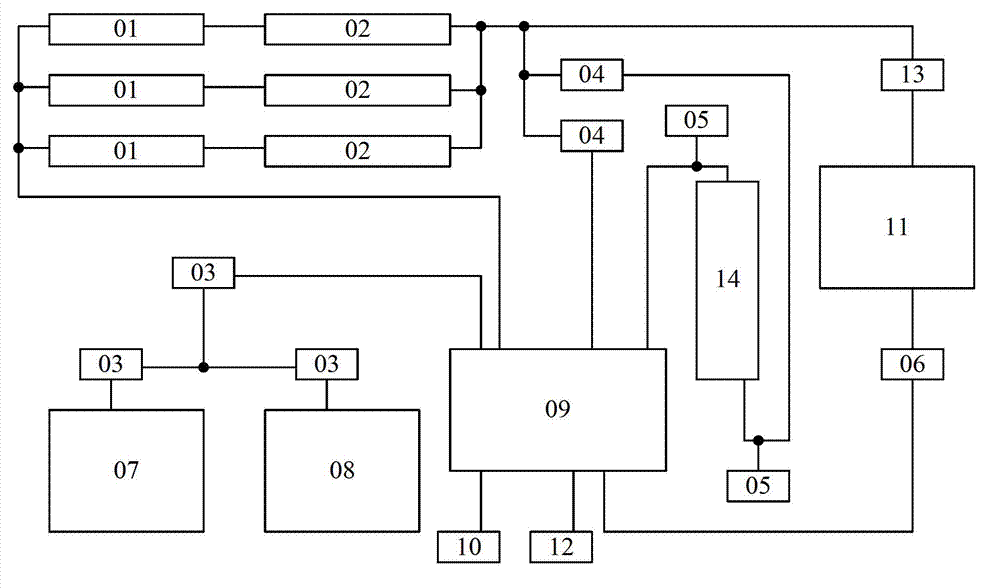

[0021] Such as figure 2 As shown, in this embodiment, in order to prevent the intensification of acid corrosion after the oxidation of the ethylene glycol solution, the corrosion inhibitor storage tank 07 and the alkali solution storage tank 08 are added to the existing ethylene glycol refrigerant circulation system, and the corrosion inhibitor storage tank 07 and the The solution output pipes of the alkali solution storage tank 08 are respectively connected to the main transmission pipe connected with the refrigerant pool 09, and a filling pump 03 is respectively installed on each solution output pipe and the main transmission pipe; a pH transmitter is installed on the refrigerant pool 09 10;

[0022] Install the first filter 02 on the refrigerant input pipeline of each heat exchanger 01;

[0023] Add a group of filter loops between the output main pipeline of the refrigerator 11 flowing to the first filter 02 and the refrigerant pool 09, and the output main pipeline is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com