Method for making foods by using pressure cooker

A pressure cooker and food technology, applied in pressure cookers, cooking utensils, household appliances, etc., can solve problems such as affecting food quality and unpleasant taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

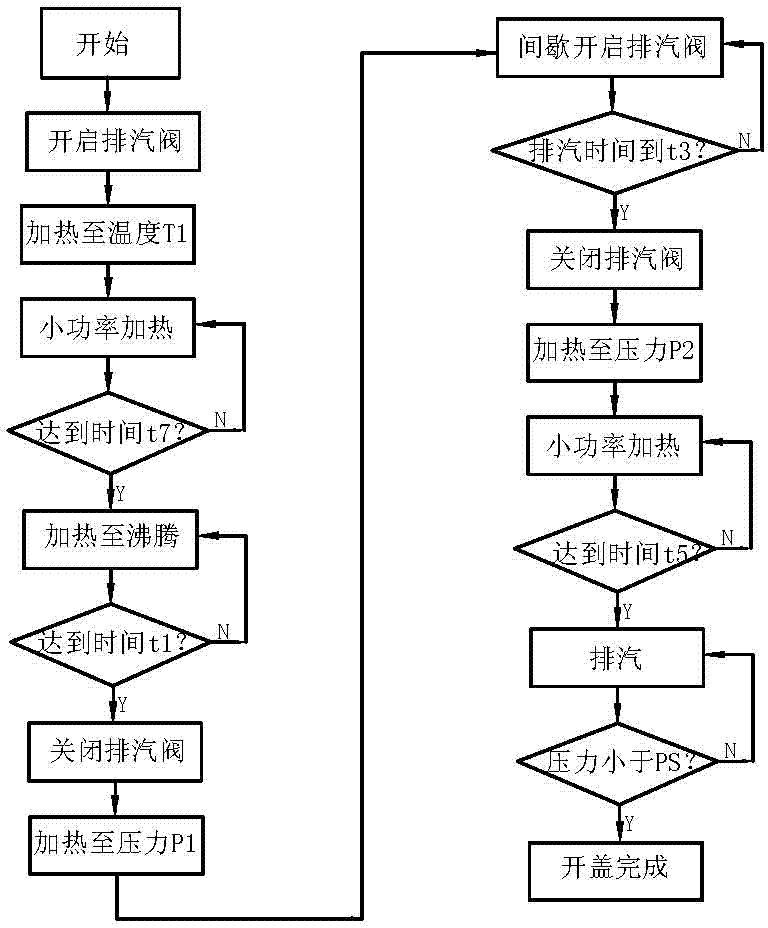

[0028] see figure 1 As shown, the first embodiment of the method for making food in a pressure cooker of the present invention, the pressure cooker includes an inner tank, a pot cover for sealing the inner tank, a heating device, an electric control device, a temperature measuring device and a pressure detection device, and the pot cover is provided with an electromagnetic Exhaust valve.

[0029] Described food is rice, and its preparation method comprises:

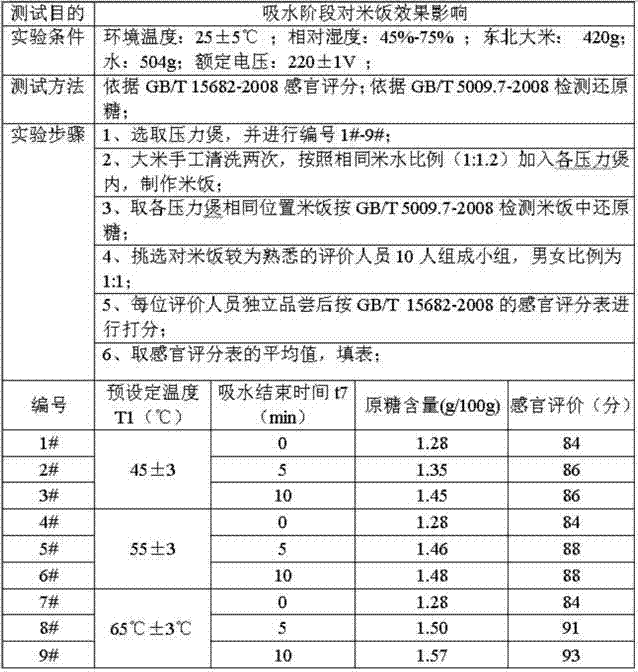

[0030] Step S11: In the water absorption stage, the electric control device drives the electromagnetic exhaust valve to open, the electric control device drives the heating device to heat the food in the inner pot, and the temperature measuring device detects the temperature T in the inner pot. Let the temperature T 1 , the electric control device controls the heating device to perform intermittent heating or low-power heating, and the electric control device calculates the time t of intermittent heating or low-power he...

Embodiment approach 2

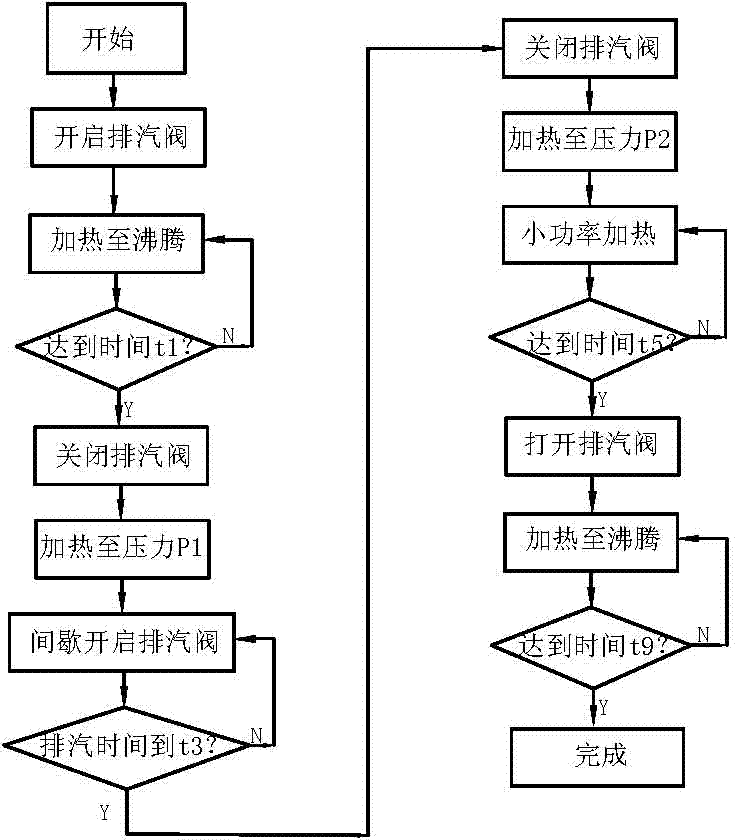

[0054] see figure 2 Shown is the second embodiment of the method for making food in a pressure cooker according to the present invention. The food is soup. In this embodiment, trotter soup is taken as an example for illustration.

[0055] Its production methods include:

[0056] S1: In the non-pressure cooking stage, the electric control device drives the electromagnetic exhaust valve to open, the interior of the inner tank is connected with the outside atmosphere, the electric control device drives the heating device to heat the food in the inner tank to boiling, and the electronic control device calculates the boiling time t, When the boiling time t is greater than the preset time t1, the pressureless cooking phase ends;

[0057] S2: In the pressure cooking stage, the electric control device drives the electromagnetic exhaust valve to close, the electric control device drives the heating device to heat and boost the food in the inner tank, and the pressure detection device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com