Full-automatic wire pole spraying robot

A technology for spraying robots and utility poles, which is applied to motor vehicles, spraying devices, transportation and packaging, etc. It can solve problems such as low efficiency, poor safety, and high labor intensity, and achieve convenient construction, high work efficiency, and low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

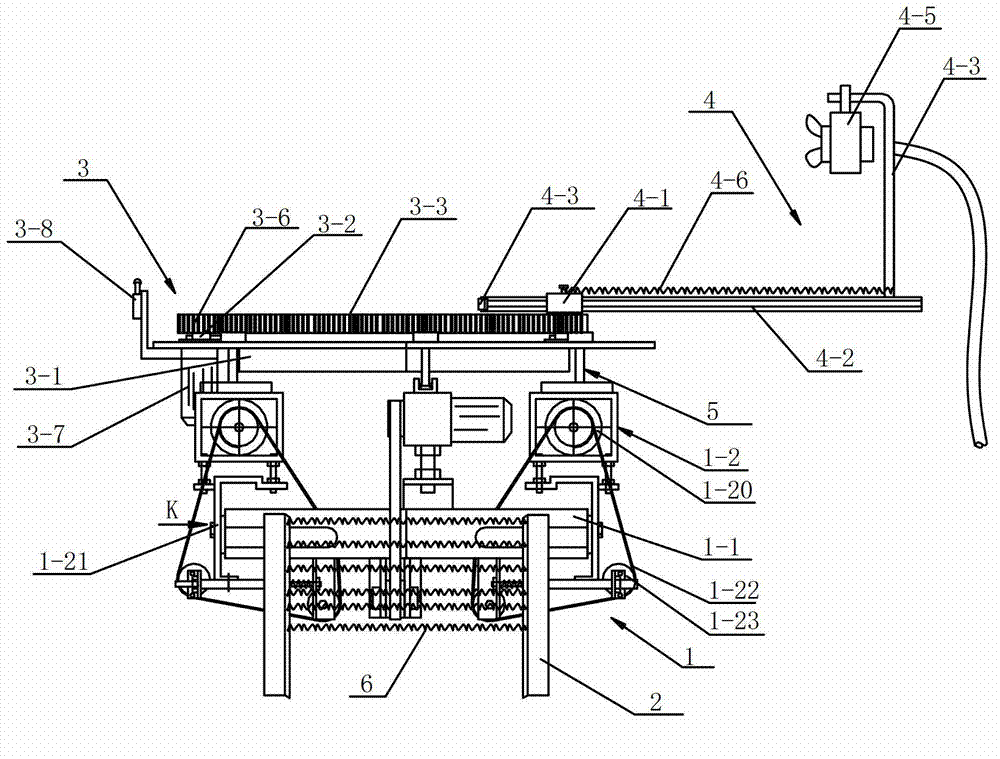

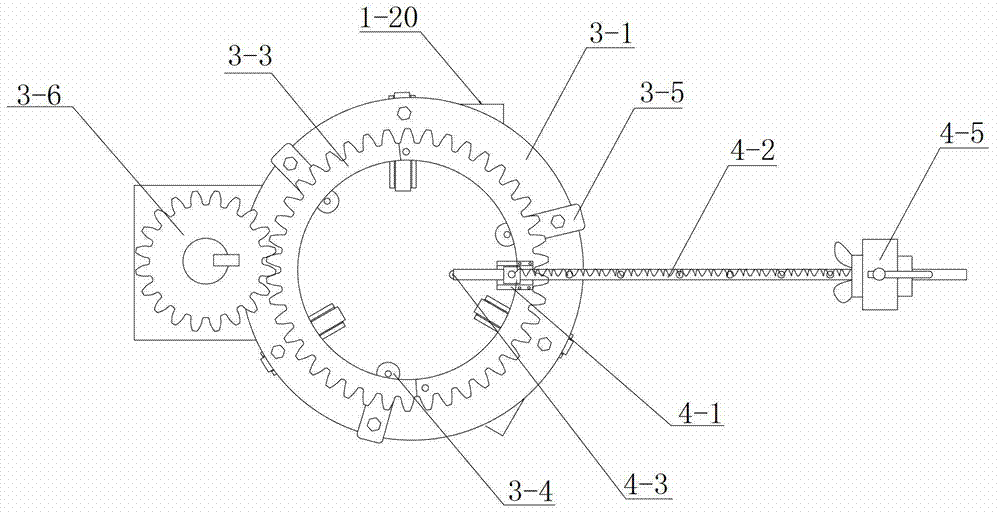

[0040] See figure 1 with figure 2 , A fully automatic telephone pole spraying robot, which mainly includes a walking mechanism 1, a chassis support 2, a rotating mechanism 3, and a spraying mechanism 4. The walking mechanism 1 is provided with three groups, and the three groups of walking mechanisms are enclosed into a circular cavity. The telephone pole 7 is installed in the annular cavity; the upper end of the walking mechanism 1 is connected to the revolving mechanism 3 through the guide mechanism 5, and the spraying mechanism 4 is installed on the upper end of the revolving mechanism 3, and the spraying mechanism 4 is installed in the revolving mechanism 3. Driven to make a 360° rotation, the upper end of each underframe support 2 is fixedly connected to each gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com