A manipulator structure for automatic loading and unloading of punch presses

A technology of automatic loading and unloading, manipulator, applied in metal processing equipment, feeding device, peeling device, etc., can solve the problems of frequent stamping die change, affecting manual operation space, frequent manual operation in small batches, etc., to achieve the effect of rapid disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

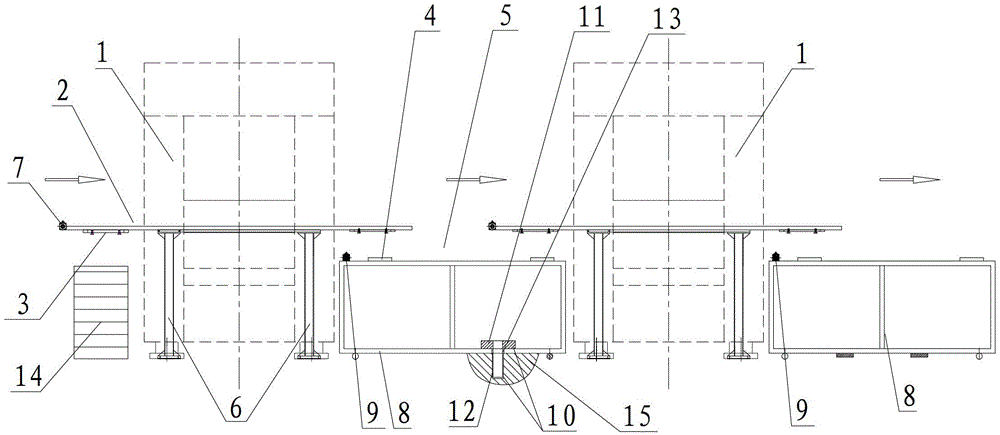

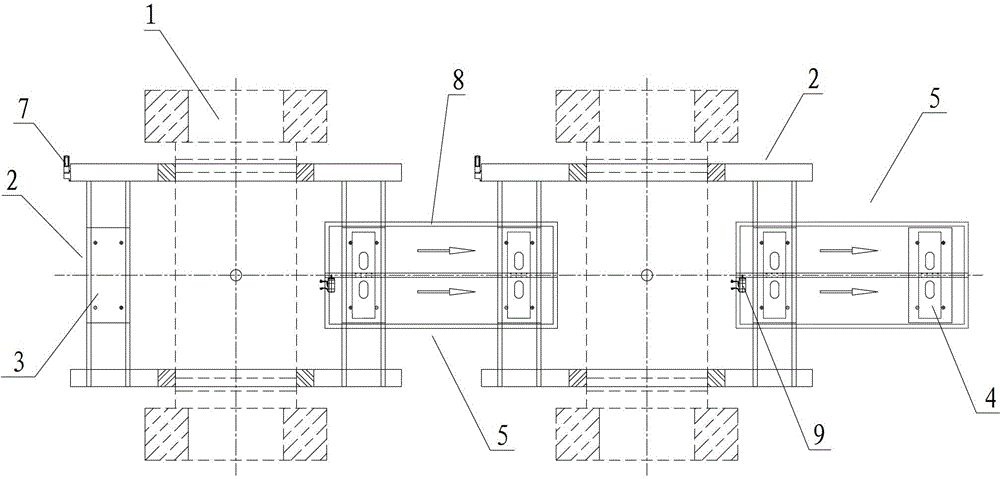

[0015] Such as figure 1 , figure 2 Shown is a method provided by the present invention, which can ensure the flexible connection of any number of punches during mass production, and can ensure that the flexible connection mechanism can be quickly removed for the automatic up and down of punches during small batch manual production or mold replacement. Material manipulator structure. The manipulator structure includes a manipulator body 2 located on both sides of the workbench of the punch press 1, and a transfer module 3 is respectively installed on the input end and the output end of the manipulator body 2, and also includes a manipulator on the input end and the output end respectively. A flexible transfer trolley 5 with a transmission module 4 installed, the flexible transmission trolley 5 is detachably installed between two adjacent punches 1, and the transmission module 4 on its delivery end and output end is respectively connected to the adjacent two punches 1 The tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com