An insulating device for the installation port of the grounding wire

An insulation device and installation port technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, electrical components, etc., can solve the difficulty of restoring the ground wire, the large friction coefficient of the rubber sleeve, and the difficulty of moving, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

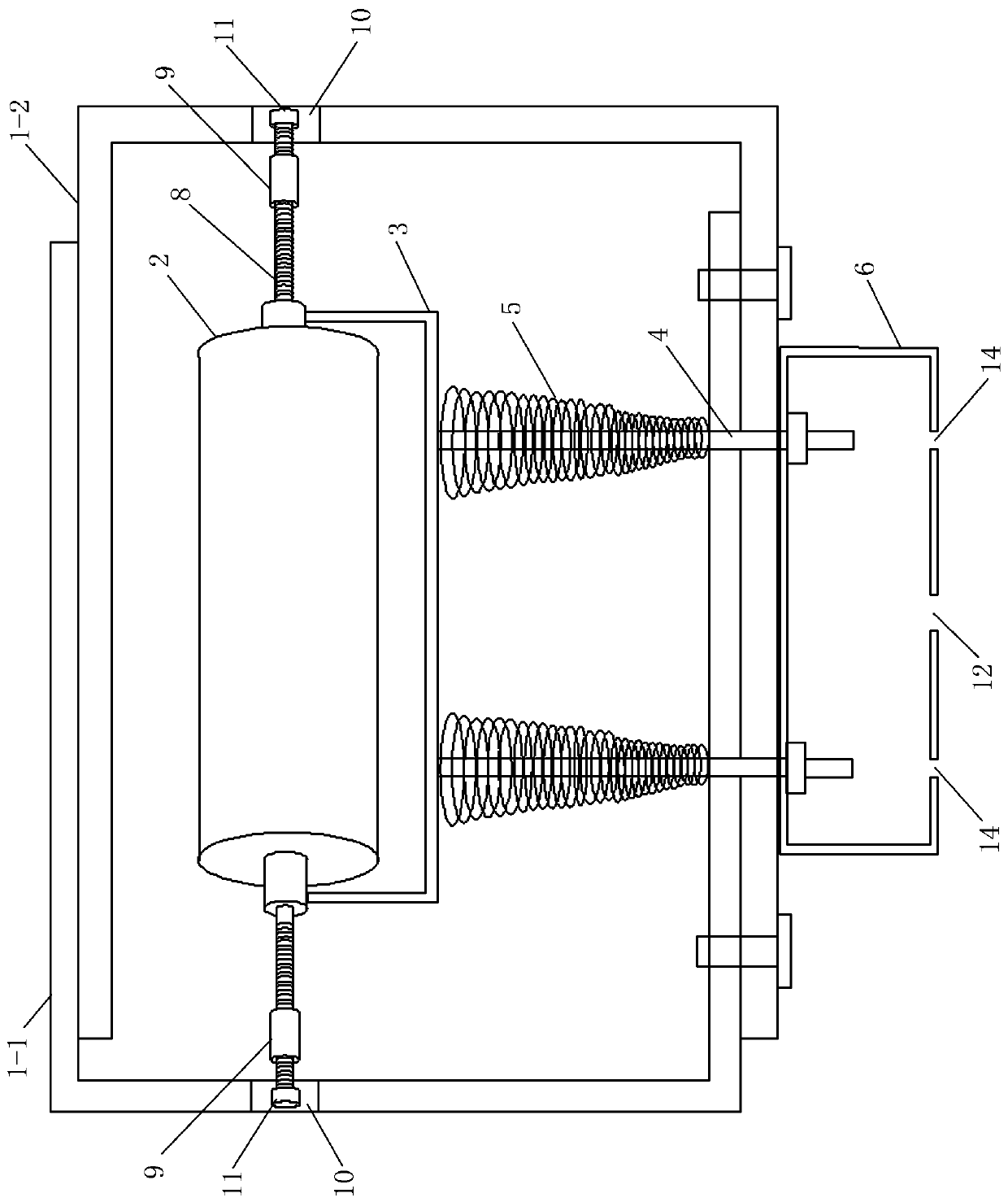

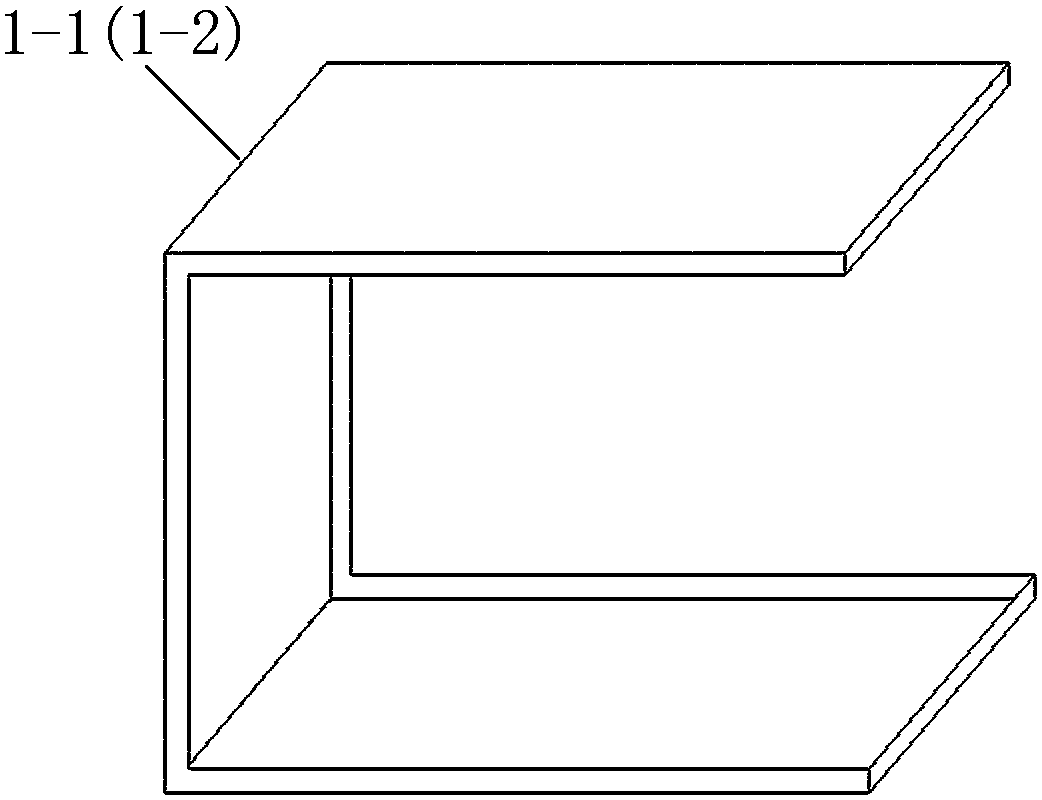

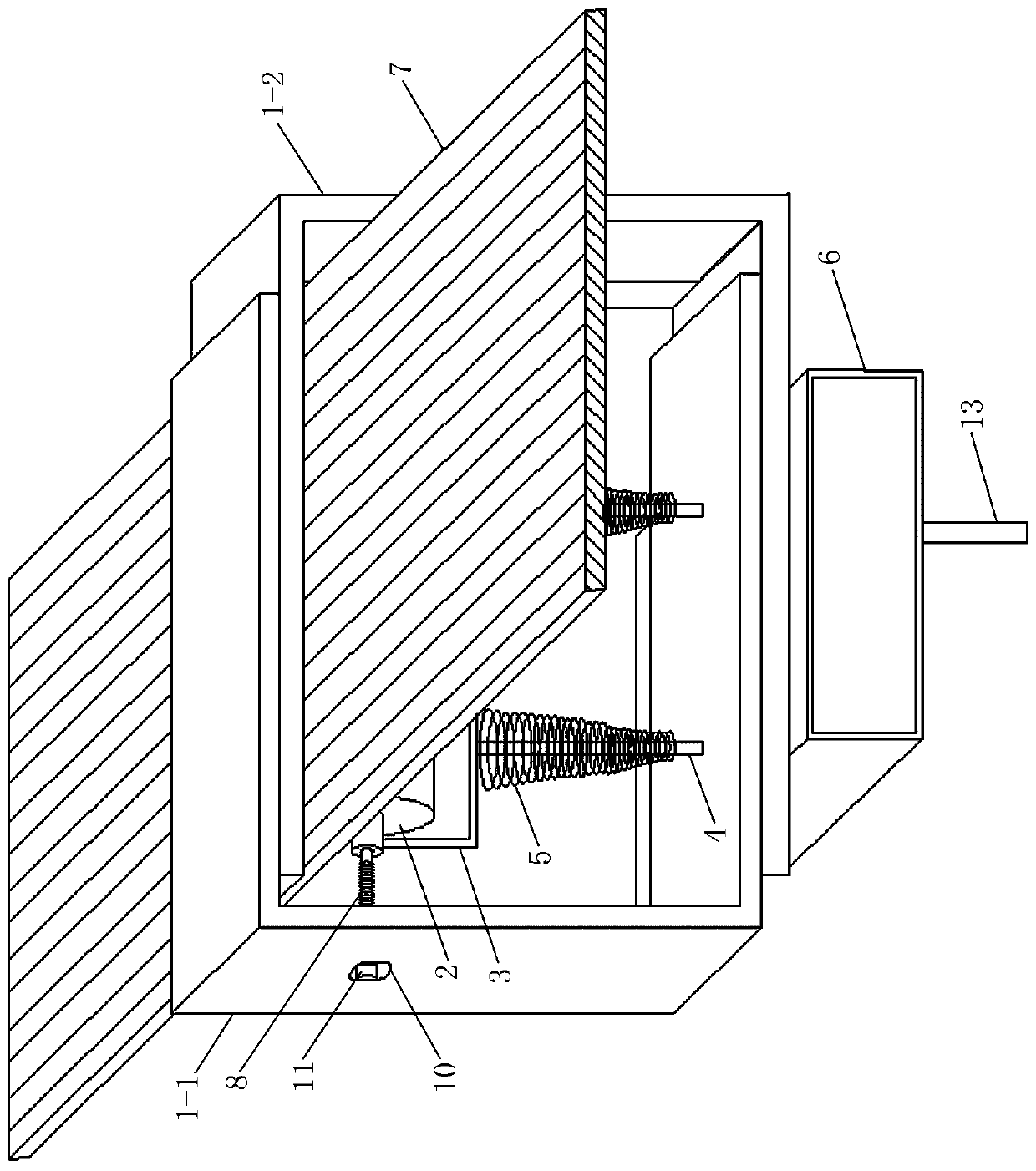

[0022] Refer to attached Figure 1~3 , the insulating device for the installation opening of the ground wire of the present invention comprises a left open box 1-1 and a right open box 1-2, the left open box 1-1 and the right open box 1-2 are semi-frame-shaped boxes with side openings, and the left opening The box 1-1 and the right open box 1-2 are staggered and stacked through the side openings to form an insulating box, and the left open box 1-1 and the right open box 1-2 are fixed by screws; the upper part of the insulating box is provided with parallel The roller 2 on the upper plane of the insulating box is connected to the two side walls of the insulating box; the two ends of the roller 2 are provided with a roller supporting frame 3; the lower part of the roller supporting frame 3 is provided with a connecting shaft 4, which is connected to A compression spring 5 is sleeved on the shaft 4; the lower part of the connecting shaft 4 passes through the bottom of the insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com