Electromechanical power steering with backlash compensation for worm gears

A technology of power steering and power steering, which is applied in the direction of power steering mechanism, electric steering mechanism, steering mechanism, etc., which can solve the problem of high force or moment, and achieve the effect of quick removal response and flexible settability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

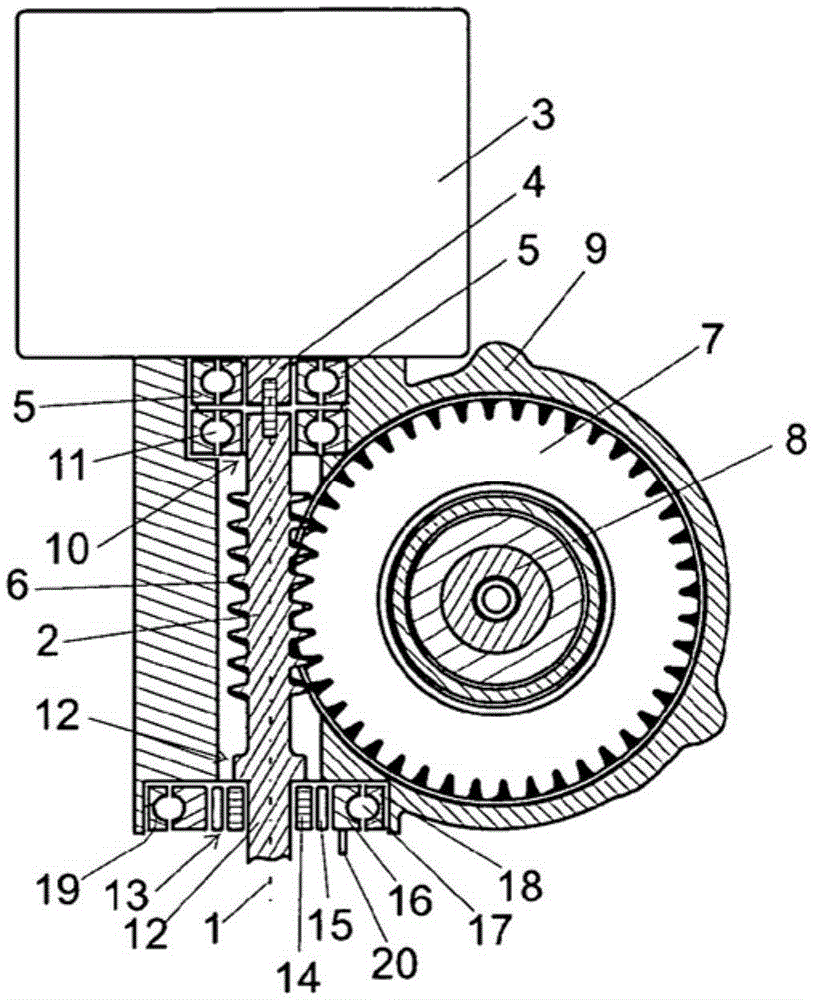

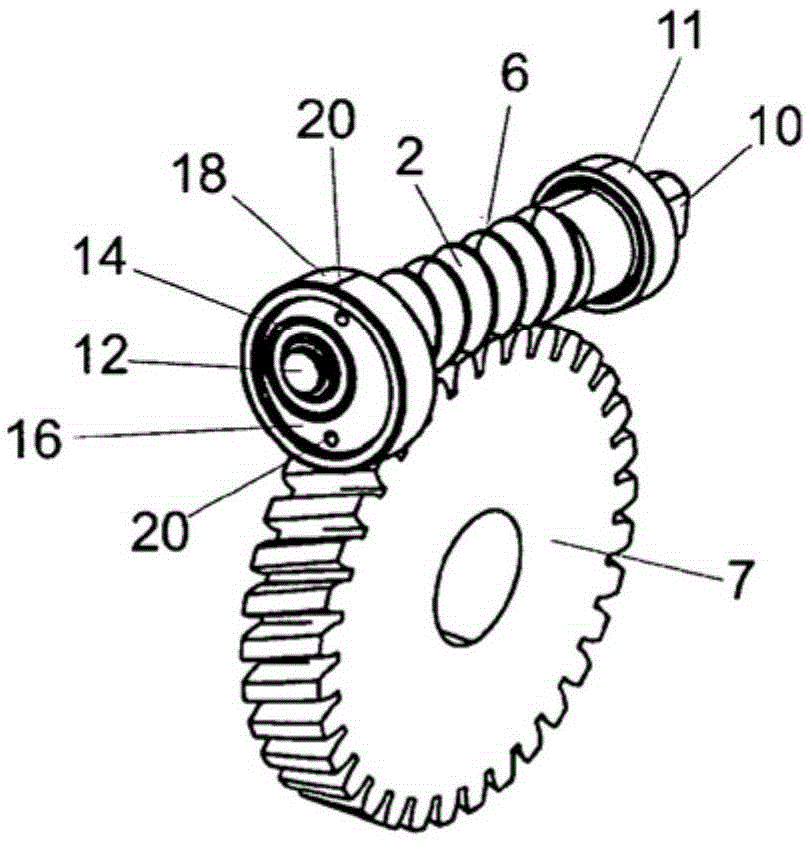

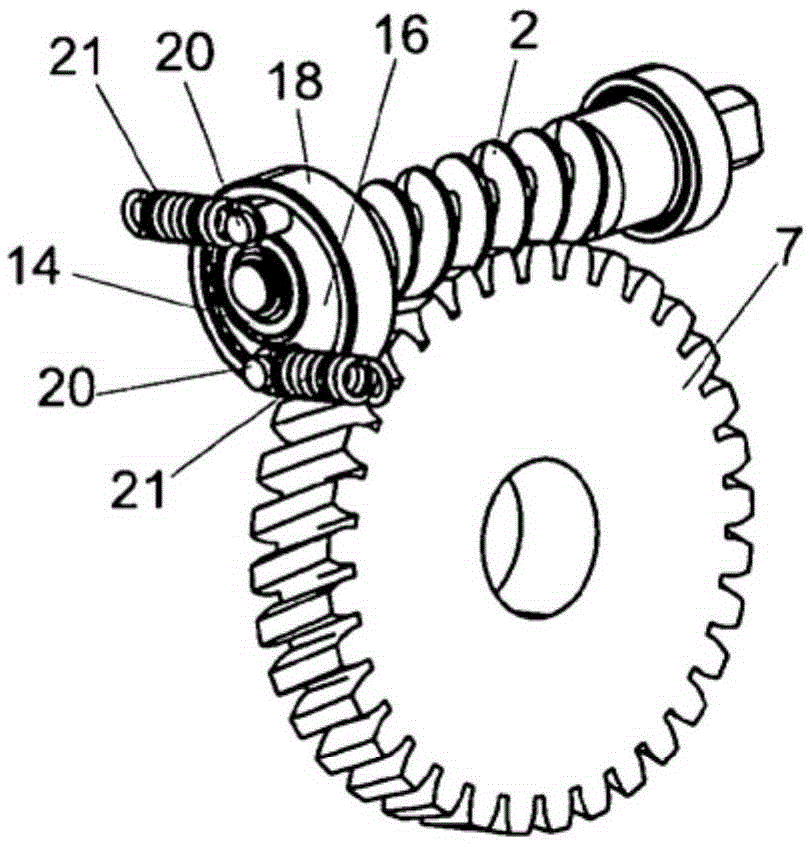

[0021] figure 1 A longitudinal section of the transmission of the electromechanical power steering is shown and extends along the axis of rotation 1 of the worm shaft 2 driven by the electric motor 3 . The electric motor 3 has a motor shaft 4 which is coupled in a rotationally fixed manner to the worm shaft 2 via a flexible coupling 5 . The worm shaft 2 meshes with a worm wheel 7 via a worm toothing 6 . The worm gear 7 is in turn connected in a rotationally fixed manner to a steering shaft 8 which extends between the not shown steering wheels of the motor vehicle and the actual steering gear.

[0022] The structural elements are accommodated in a common transmission housing 9 .

[0023] The mounting of the worm shaft 2 in the housing 9 takes place in a conventional roller bearing 11 designed as a ball bearing at the motor-side end 10 of the worm shaft 2 . The ball bearing 11 is designed such that a small axial movement of the worm shaft 2 relative to the housing 9 and a sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com