Double station flour packing machine and packing method thereof

A dual-station, packaging technology, used in packaging, packaging machines, transportation packaging, etc., can solve the problems of no coordination mechanism, low component utilization, and high cost, reducing labor intensity, saving labor time, and occupying area. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

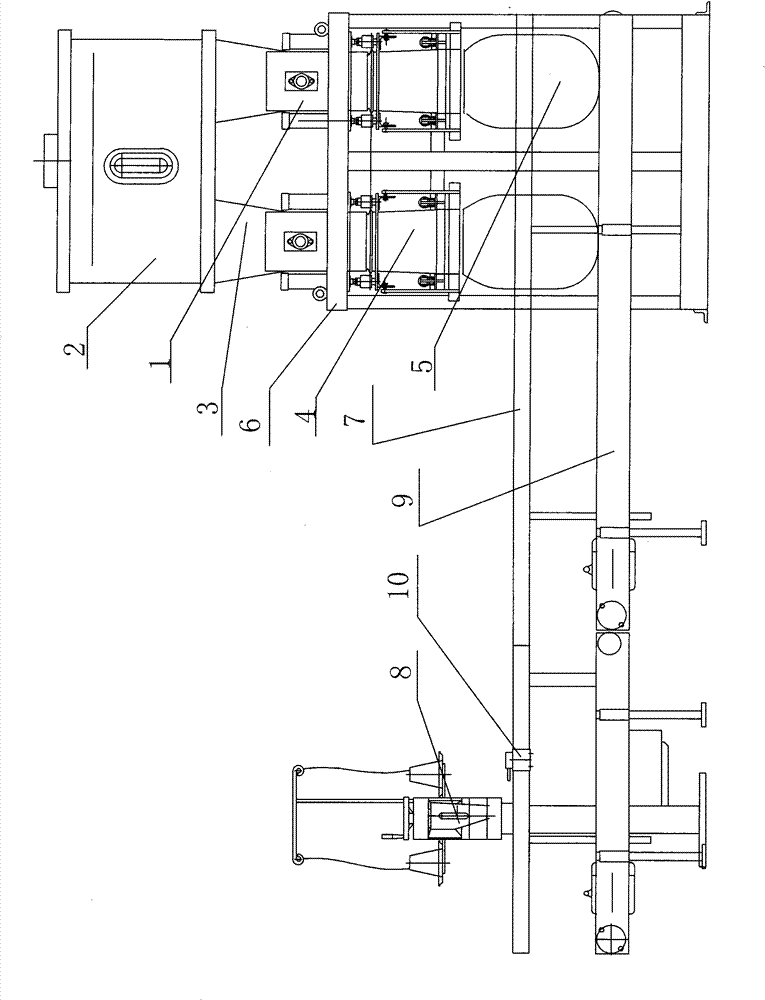

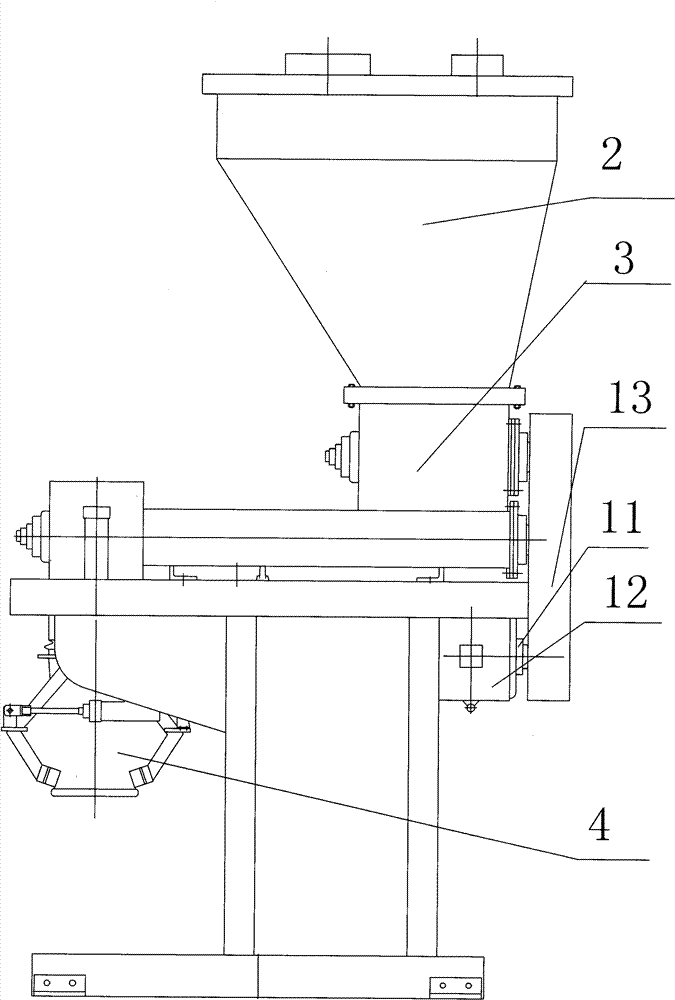

[0031] Double-station flour packaging machine, its composition includes: a double feeder 1 with a power mechanism and a charging bin 2, the bottom of the charging bin 2 is connected to the agitator 3, and the agitator 3 is connected to the feeder 1 , the bottom of the feeder 1 is connected to the bag-clamping mechanism 4, and the bottom of the bag-clamping mechanism 4 is connected to the charging bag 5; the bag-clamping mechanism 4 and the charging bag 5 are all loaded in the frame 6, and the frame 6 is connected to the conveyor 7, and the conveyor 7 is connected to the sewing machine 8.

[0032] In the double-station flour packaging machine, the conveyor 7 is equipped with a conveyor belt 9, an electronic scale and a travel switch 10; there are two agitators, feeders, bag clamping mechanisms and charging bags.

Embodiment 2

[0034] In the double-station flour packaging machine described in Embodiment 1, the power mechanism 11 includes a motor 12 , the motor 12 is connected to a speed change mechanism 13 , and the speed change mechanism 13 is connected to the feeder 1 .

Embodiment 3

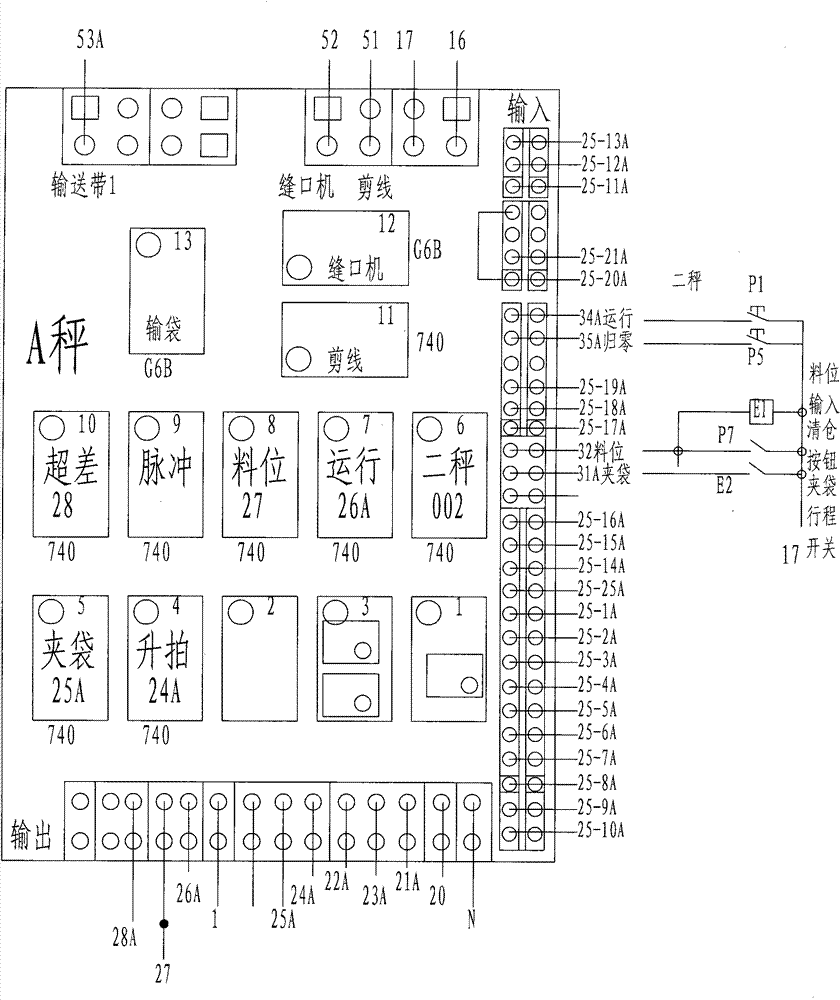

[0036] Embodiment 1 or 2 double-station flour packaging method, first detect the double-station flour packaging machine A, B clip bag input signal, if it is detected that A, B scales have a clip bag number, then the instrument clip bag A, B output, If there is a material level input signal at this time, the instrument will output a frequency conversion operation signal, and at the same time start the large, medium and small feed signals for fast feeding. When the weighing value > target value - one stage value, turn off the large throwing signal equipment and carry out medium-speed feeding. When the weighing value > target value - the second stage value, turn off the second signal device and enter the slow feeding process. When the weighing value > target value - drop value, the instrument stops outputting the frequency conversion operation signal, the equipment stops feeding, and outputs the Finsh completion signal . The equipment enters the vibration bag process). When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com