Automatic continuous pretensioning equipment for chains with accessories

A continuous and chain technology, applied in the direction of metal chains, etc., can solve the problems of unsuitable sustainable development, high labor cost, high labor intensity, etc., and achieve the effect of simple and practical appearance, convenient operation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

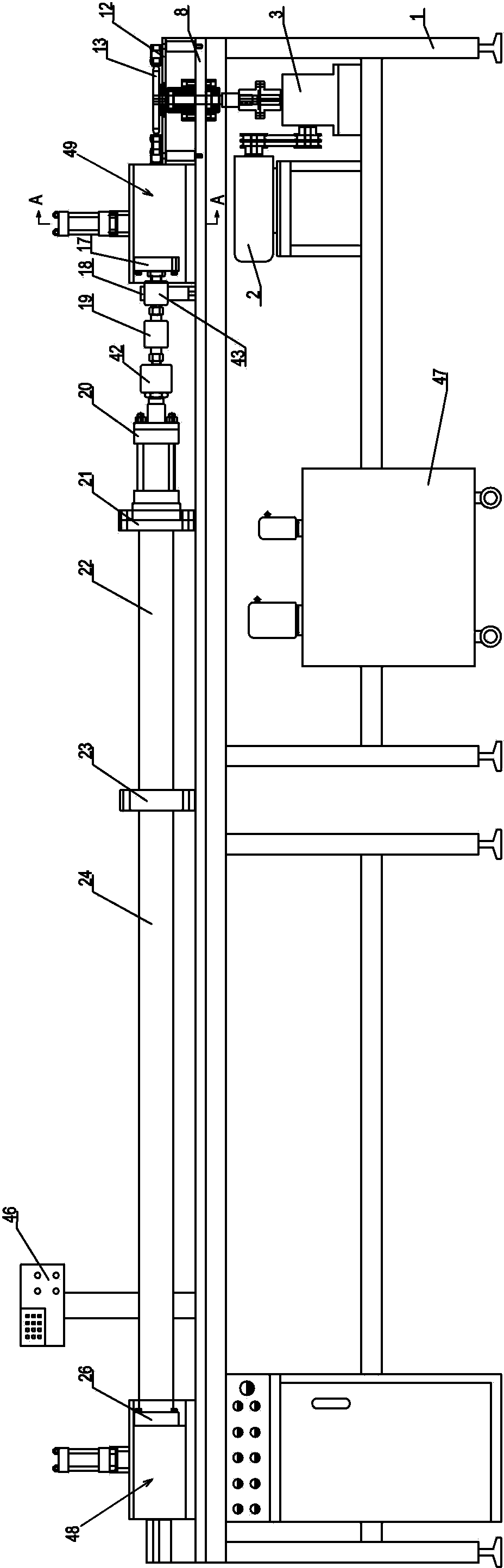

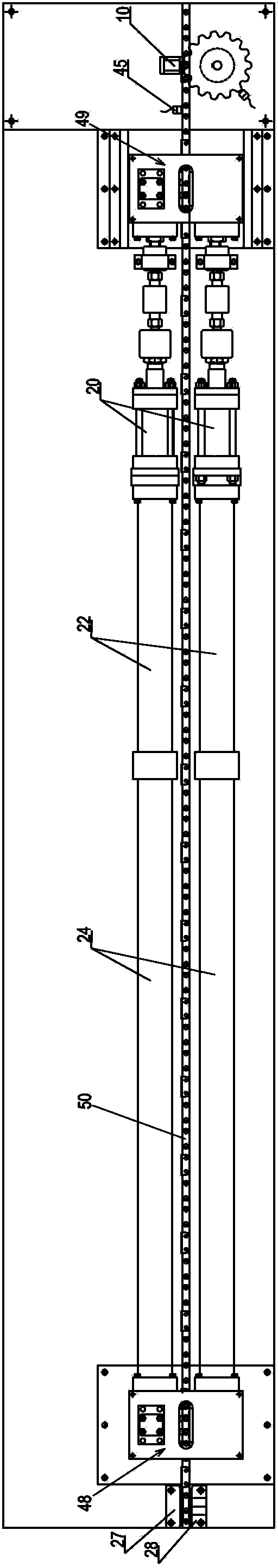

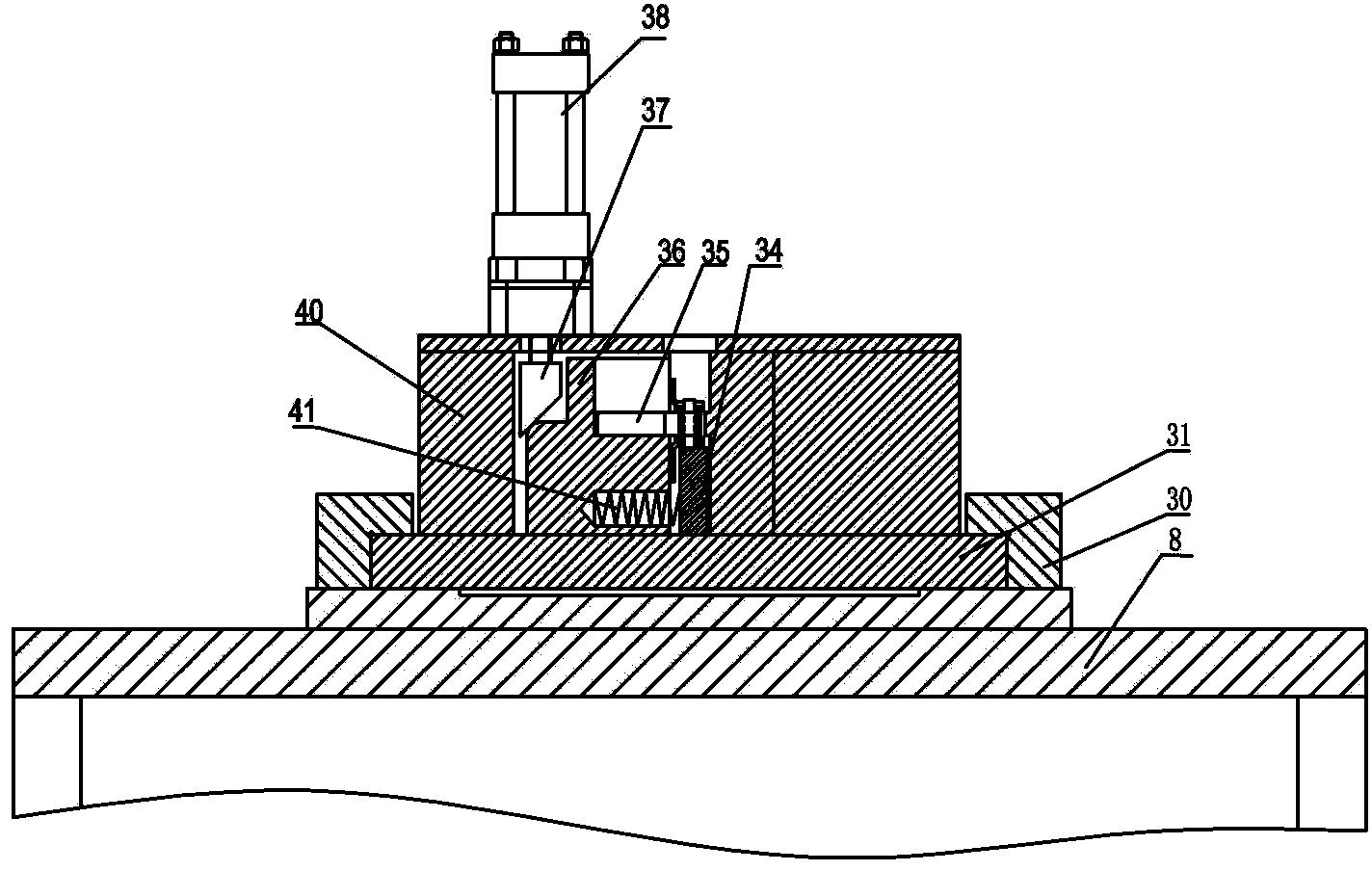

[0019] like figure 1 , figure 2 The shown automatic continuous chain pre-tensioning equipment with accessories includes a body 1, and one end of a platform 8 of the body 1 is provided with two feed inlet guide rails 27, 28, and a feeder rail 27, 28 is formed between the two feed inlet guide rails 27, 28. Feed chute for slipping of attachment chain 50 having a support bottom for supporting one side of the attachment chain and the end of the pin and a side slot for receiving the attachment plate of the attachment chain The other end of the body 1 platen 8 is provided with an outlet table 12, and the outlet table 12 is rotated to be provided with a sprocket 13 that rotates in a horizontal plane and a guide rail 10 that impels the belt accessory chain 50 to mesh with the sprocket 13, and the sprocket 13 The reducer 3 is connected to the motor 2 through transmission; two chain clamping mechanisms 48, 49 are installed on the platform 8 of the body 1, one chain clamping mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com