Large-size wind turbine gear shaft tooth grinding tooling

A gear shaft and wind power technology, which is applied in gear tooth manufacturing devices, belts/chains/gears, gear teeth, etc., can solve problems such as inability to guarantee special structures, achieve uneven tooth thickness, stable positioning, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

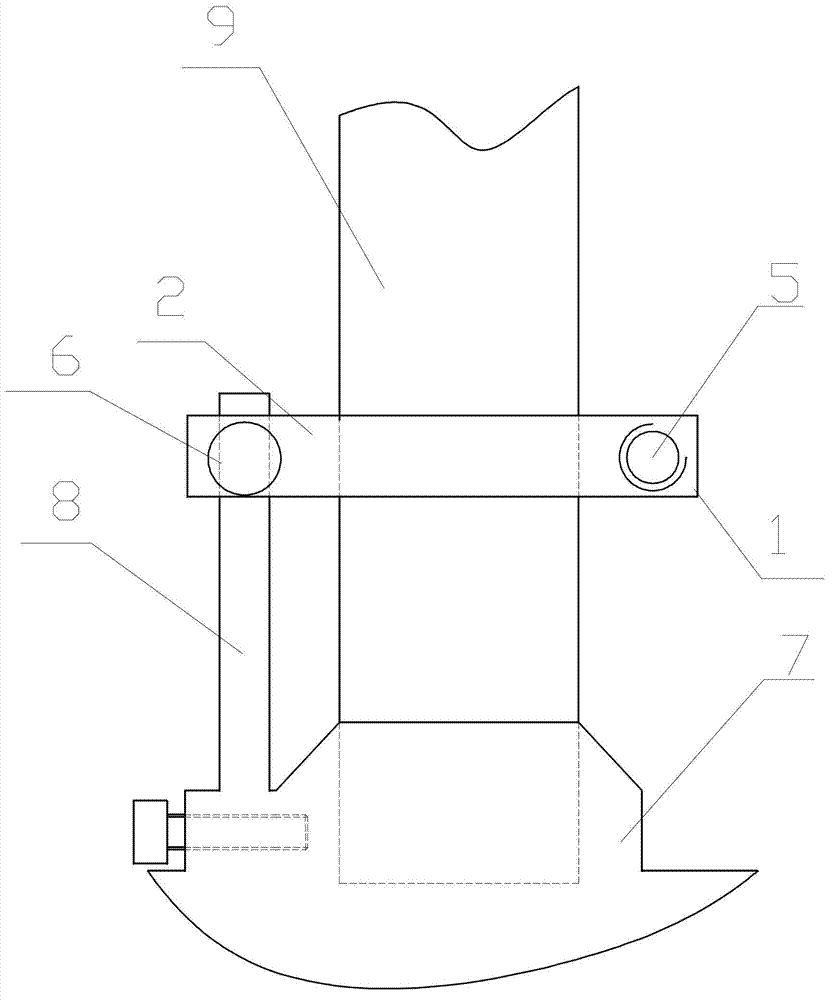

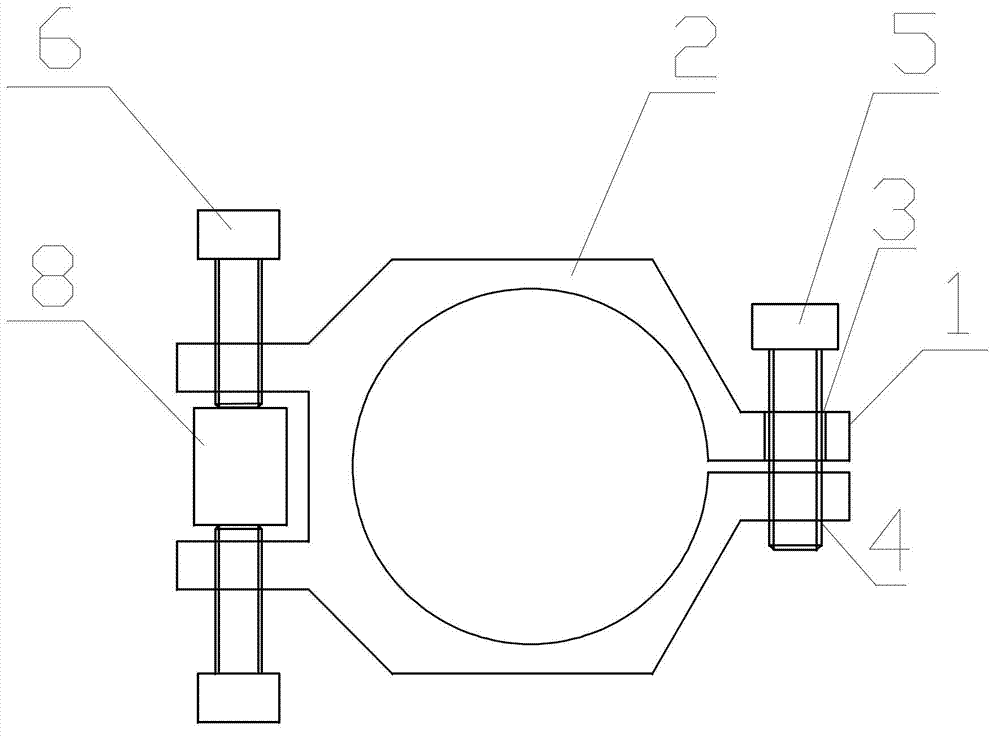

[0013] like Figure 1~2 As shown, the large-scale wind power gear shaft grinding tooling provided by the present invention includes a shaft sleeve 2 with an open end 1 for tightening the gear shaft to be processed, and the open end 1 of the shaft sleeve 2 has a screw hole 13, a screw hole II 4. Bolt 5 is screwed into screw hole I 3 and screw hole II 4 and tightened so that the shaft sleeve clamps the gear shaft to be processed, and the other end of the shaft sleeve 2 is fixed on the support 8 of the spindle workbench 7 with the fixing bolt 6 .

[0014] During use, select the appropriate shaft sleeve 2 according to the size of the gear shaft 9 to be processed, clamp one end of the gear shaft 9 to be processed on the main shaft workbench 7, put the shaft sleeve 2 on the gear shaft 9 to be processed, and the shaft sleeve 2 One end is fastened to the workbench bracket 8 with the fixing bolt 6, and the top of the gear shaft 9 to be processed is tightened with the top, and the open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com