All-position automated pipe preheating system

An all-position, pipe-fitting technology, which is applied in the field of pipe-fitting all-position automatic preheating systems, can solve problems such as the inability to guarantee the welding quality of large-diameter pipe fittings, the inability to accurately control the preheating temperature, and unstable gas control, etc., to achieve precise temperature control, Effect of correcting preheating temperature and automatic preheating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

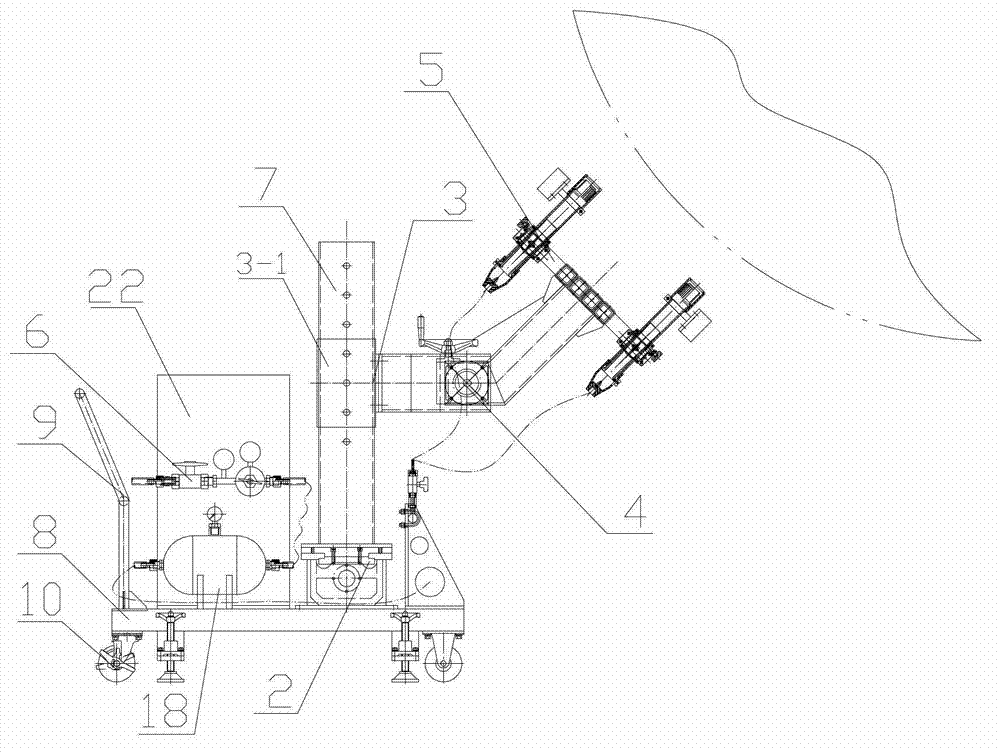

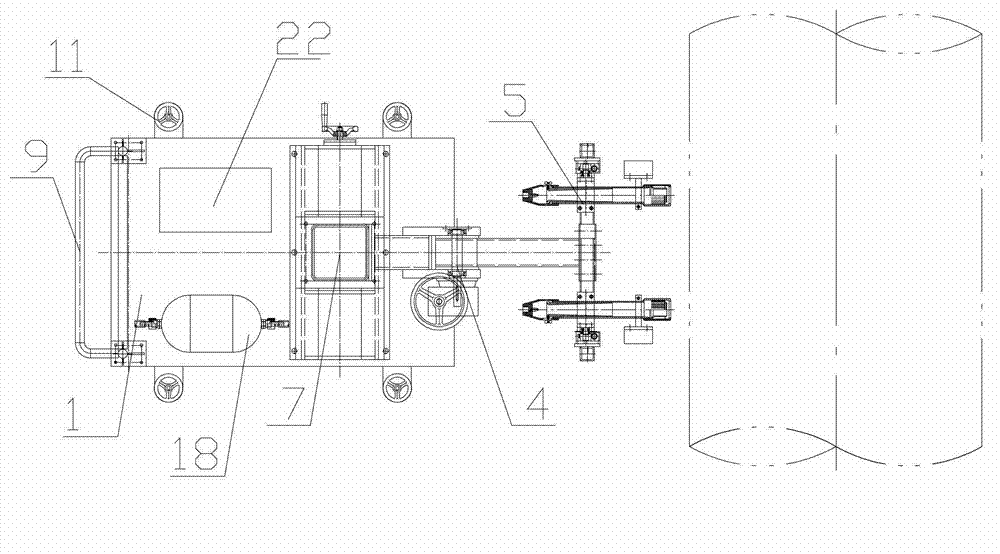

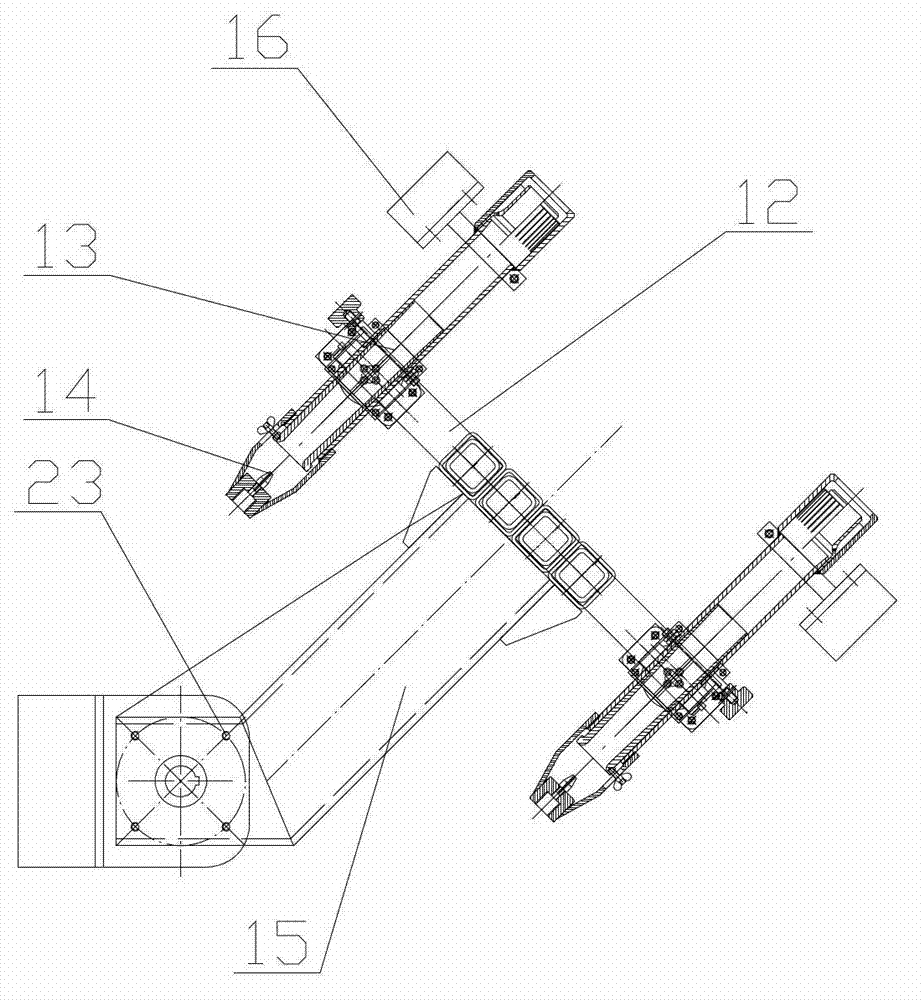

[0015] An all-position automatic preheating system for pipe fittings provided in this embodiment has a structure such as Figure 1 to Figure 2 As shown, it includes a mobile trolley 1 and an adjustment slide plate 2 installed on the mobile trolley 1, a lifting adjustment device 3, an angle adjustment mechanism 4, a gun head part 5, and an air circuit system 6. An adjustment slide plate 2 is installed on the mobile trolley 1 to adjust The slide plate 2 is equipped with a screw pair transmission mechanism, and a column 7 is vertically installed on the screw pair transmission mechanism, and the column 7 is driven by the screw pair to translate along the adjustment slide plate; the lifting adjustment device 3 has a sleeve mechanism 3-1 sleeved on the column 7, there are corresponding pin holes on the column 7 and the sleeve mechanism 3-1, and the height of the lifting adjustment device is adjusted by inserting a pin shaft in the pin hole; one end of the angle adjustment mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com