Air brake system for automatic program management (APM) vehicle

An air brake and air control technology, applied in the field of urban rail vehicle braking system, can solve the problems of high cleanliness requirements of compressed air, high price, inability to expand functions, etc., and achieve good control accuracy, function expandability, and flexibility. Effect of Brake Cylinder Pressure Regulation Capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

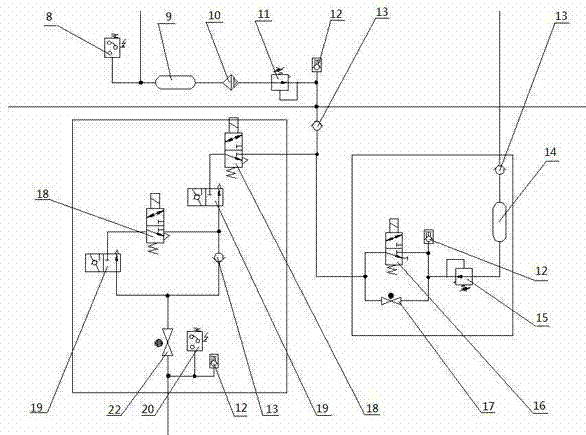

[0038] The brake system of the present invention is a simulated direct air brake system controlled by a microcomputer. It works in coordination with the electric brake during normal braking, and has the functions of emergency braking, holding brake and parking brake at the same time. The specific structure diagram is shown in figure 1 .

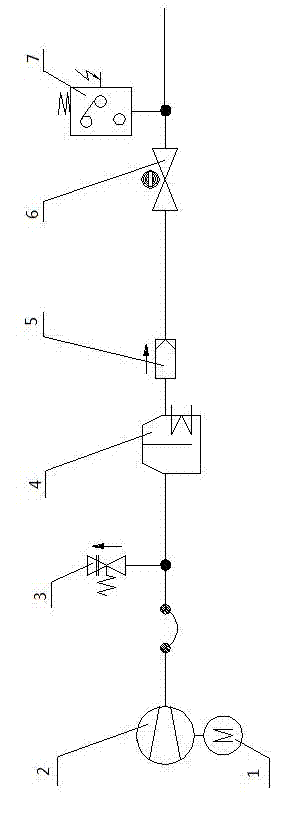

[0039] The air source of the air braking system of the present invention is an air supply module, which is integrated in a frame and elastically suspended under the underframe of the vehicle body. The air supply module can provide clean and dry compressed air for the brake system and other air-consuming parts of the vehicle. Its schematic diagram is as follows figure 2 As shown, an AC380V three-phase AC motor 1 drives an air compressor 2 with a rated displacement of 320L / min, which forms dry and clean compressed air after passing through a double-tower dryer and an air filter. The safety valve 3 is used to prevent the output compressed ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com