Manual winding device for cold stop pipe

The technology of a winding device and a winding mechanism is applied in the field of manual winding devices for cold-stopped pipes, which can solve the problems of uneven disks, waste of cold-stopped pipes, inconvenient clinical operation by medical personnel, etc., and achieves the effects of convenient operation and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

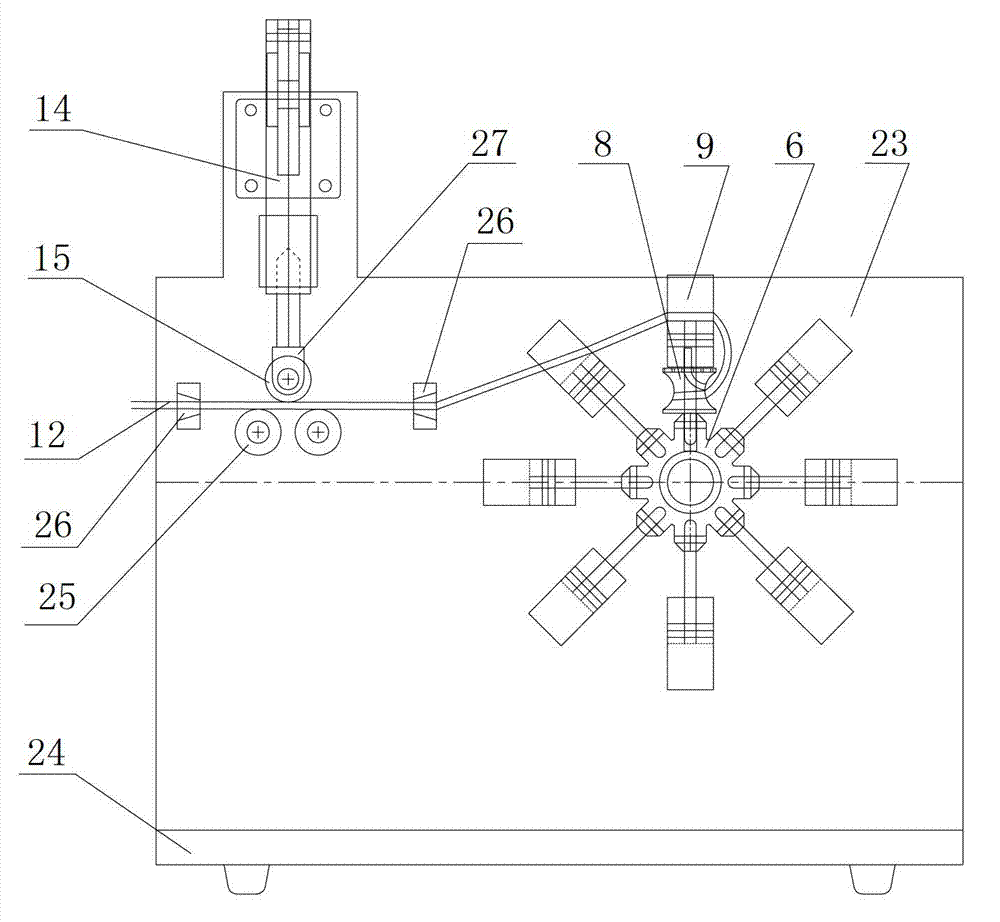

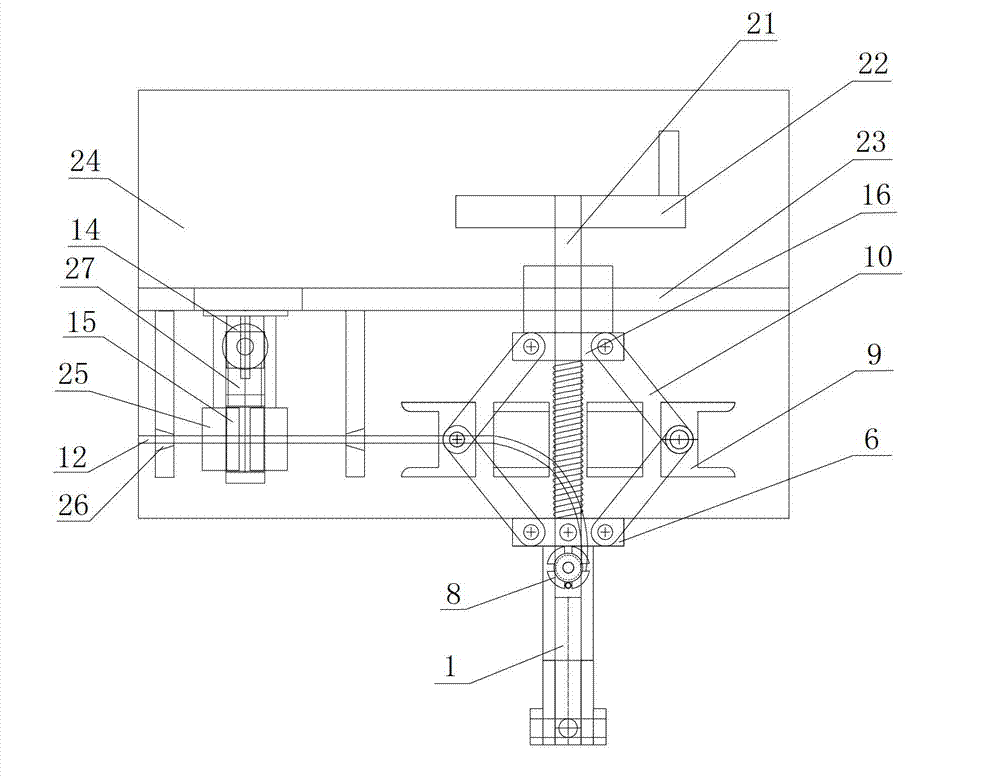

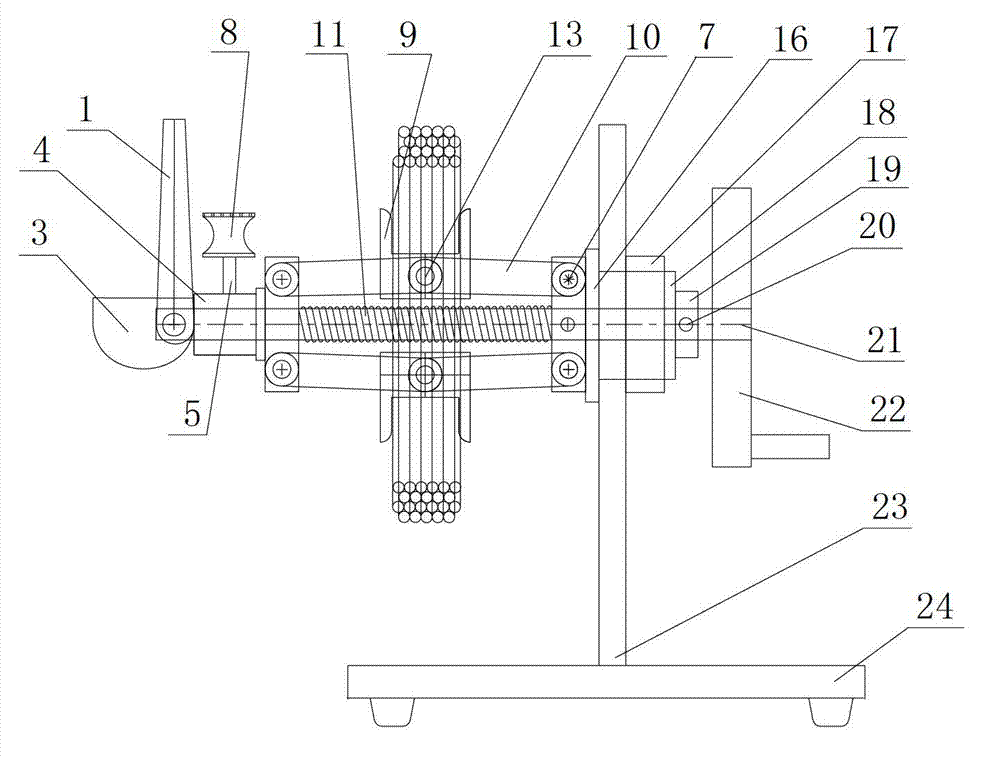

[0019] see figure 1 and figure 2 , the cold stop tube manual winding device, including a base plate 24, a mounting plate 23 vertically fixed to the base plate, and a central shaft 21 that passes through the central shaft sleeve 18 and is mounted on the mounting plate. The central shaft on one side of the mounting plate is provided with a cold stop tube winding mechanism, a winding fixed wheel 8 and a cam mechanism for controlling the opening or closing action of the cold stop tube winding mechanism, and the central shaft end on the other side of the mounting plate The central shaft handwheel 22 is installed on the top, and the winding guide mechanism that can play a damping guiding role is housed on the mounting plate 23 positioned at the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com