Construction method for quick joint of prestressed concrete tubular pile and special bending test device

A technology of concrete pipe piles and construction methods, which is applied to foundation structure tests, sheet pile walls, foundation structure engineering, etc., and can solve problems such as quality being affected by human factors, weak pile welding, and partial welds are not full, etc. Achieve the effects of shortening the connection time, easy quality assurance, and short pile connection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0046] Example 1

[0047] The construction method, construction process and operation points of the prestressed concrete pipe pile quick joint are as follows:

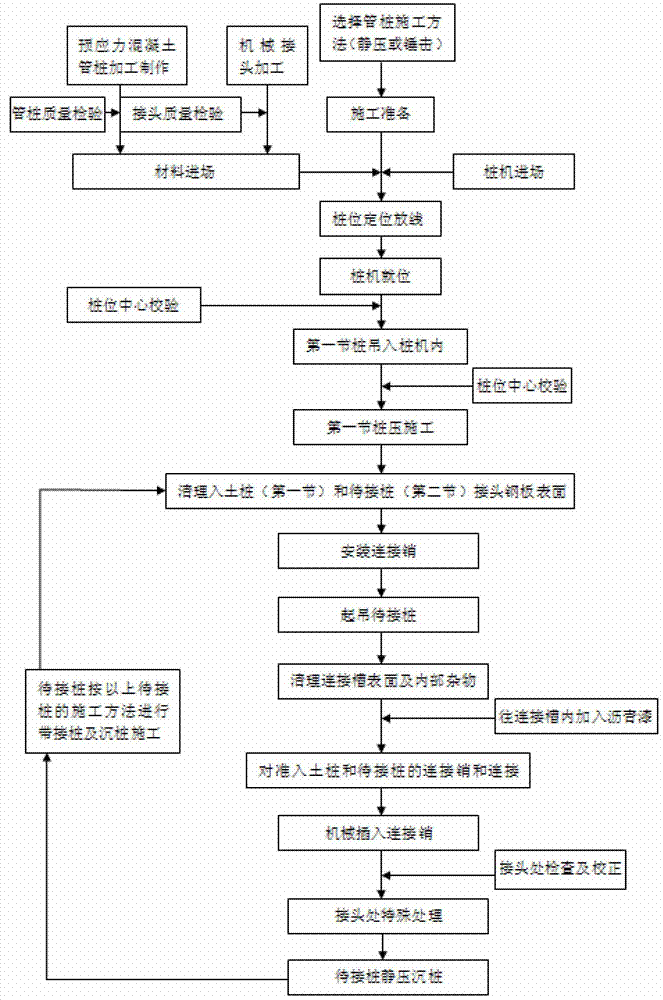

[0048] 1.1 Pipe pile mechanical quick joint construction process: see the pipe pile mechanical quick joint construction process figure 1 .

[0049] 1.2 Operating points

[0050] 1.2.1 Machining process of mechanical quick coupling parts

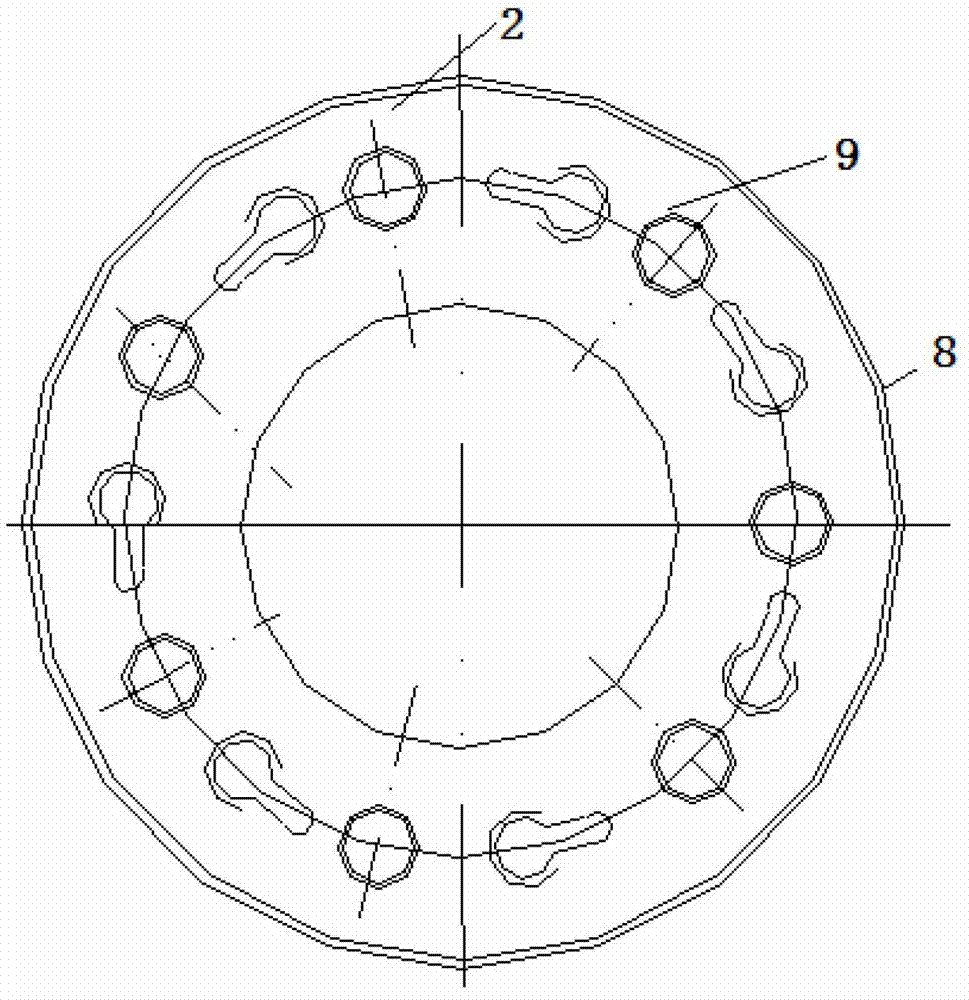

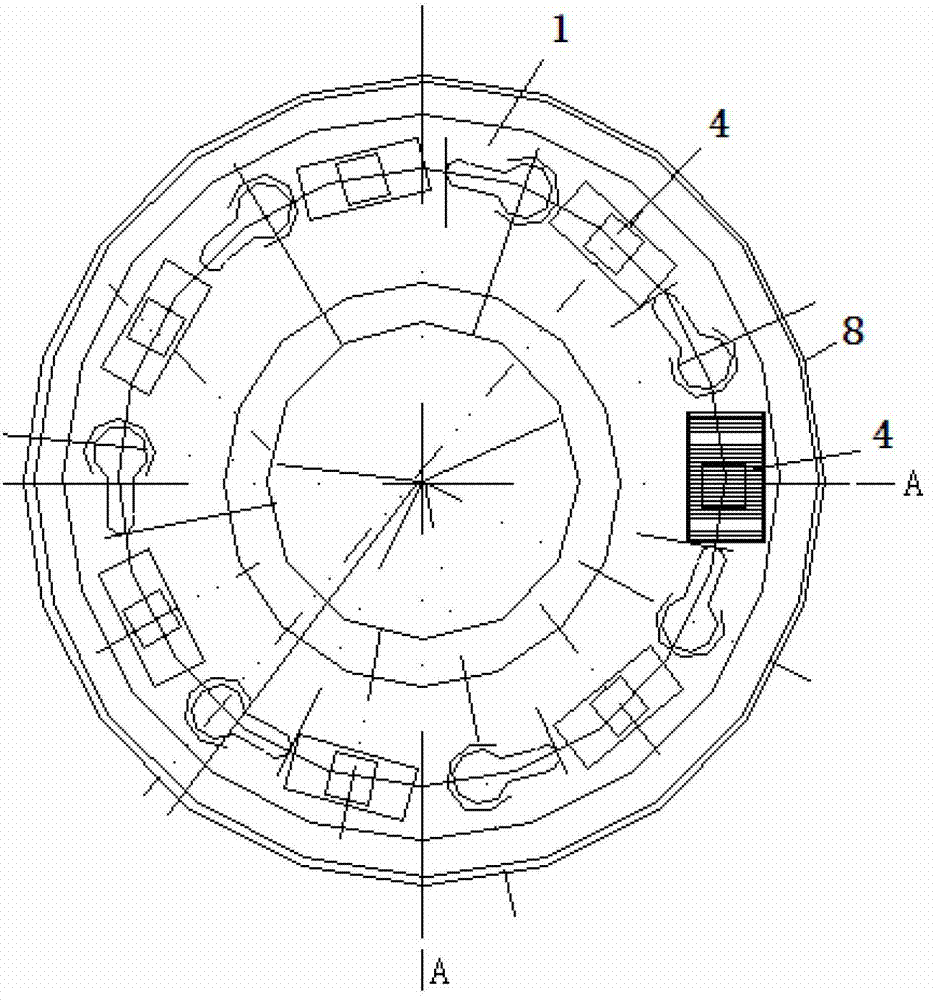

[0051] 1) The structure of the mechanical joint: The mechanical joint is welded on the embedded steel plate of each joint of the pipe pile end, and several connecting grooves for connecting the pile are welded equally. The steel pin plate and the pressure spring are embedded. The structure of the mechanical joint is shown in Figure 2-5 .

[0052] 2) The production process of mechanical quick coupling parts:

[0053] ① According to the selected prestressed pipe pile type and pile diameter, the mechanical quick joint components are designed and processed. The design principle of mechanical quick ...

Example Embodiment

[0172] Example 2

[0173] A prestressed concrete pipe pile quick joint construction method: use a special mechanical joint for pipe pile connection, and use a special construction method for prestressed concrete pipe pile joint construction during the connection process; among them:

[0174] The special mechanical joint is composed as follows: the lower section pile body 1, the upper section pile body 2, the steel pin plate 3, the connecting groove 4, the connecting pin 6; among which: the lower section pile body 1 and the upper section pile body 2 are mutually axially They are arranged in a parallel or overlapping manner. The lower section 1 and the upper section 2 are respectively provided with at least 3 axially blind hole-shaped and interconnected connecting grooves 4 arranged along the circumference; the upper and lower parts of the connecting pin 6 They are respectively located in the upper connecting groove 4 of the upper section pile body 2 and the lower section pile body 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com