Ceramsite concrete wall panel system and installation process thereof

A technology for concrete and concrete beams, which is applied in the treatment of walls, building materials, building materials, etc., can solve the problems such as the inability to combine functions such as thermal insulation, heat insulation and sound insulation, long construction period and high energy consumption, and achieve sound insulation and sound insulation. Good thermal insulation effect, small self-weight and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be described below in conjunction with the examples.

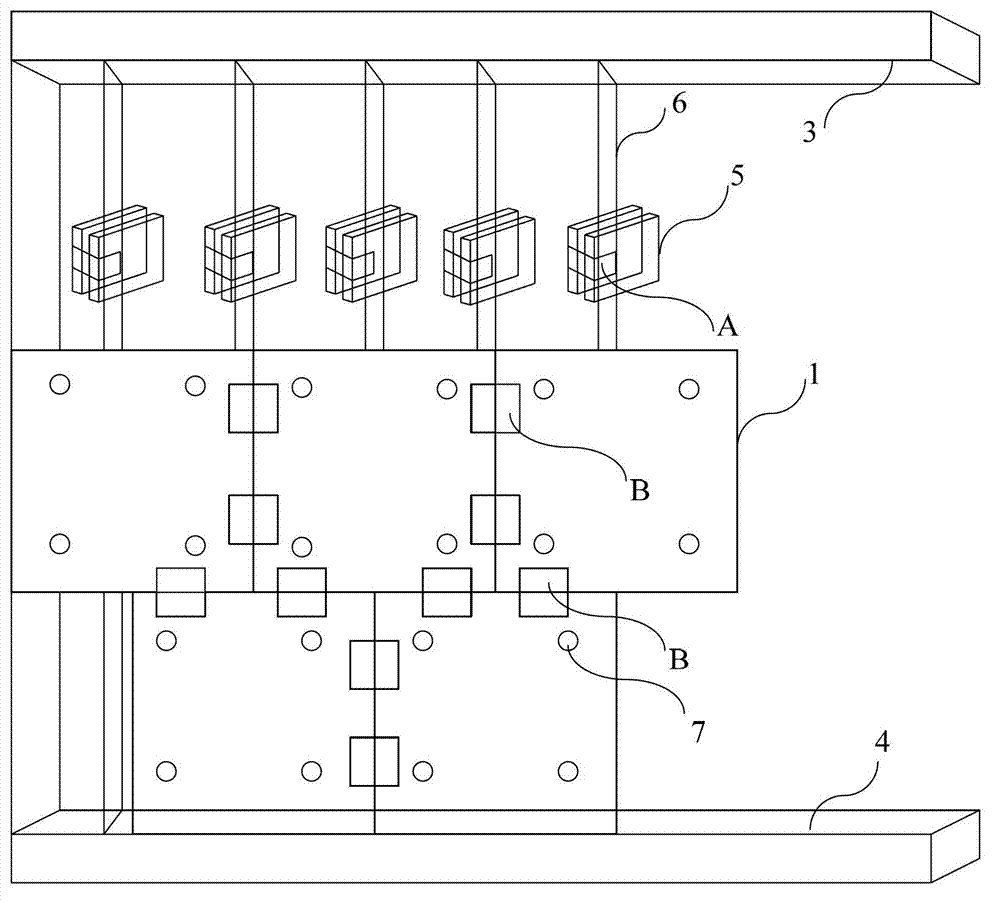

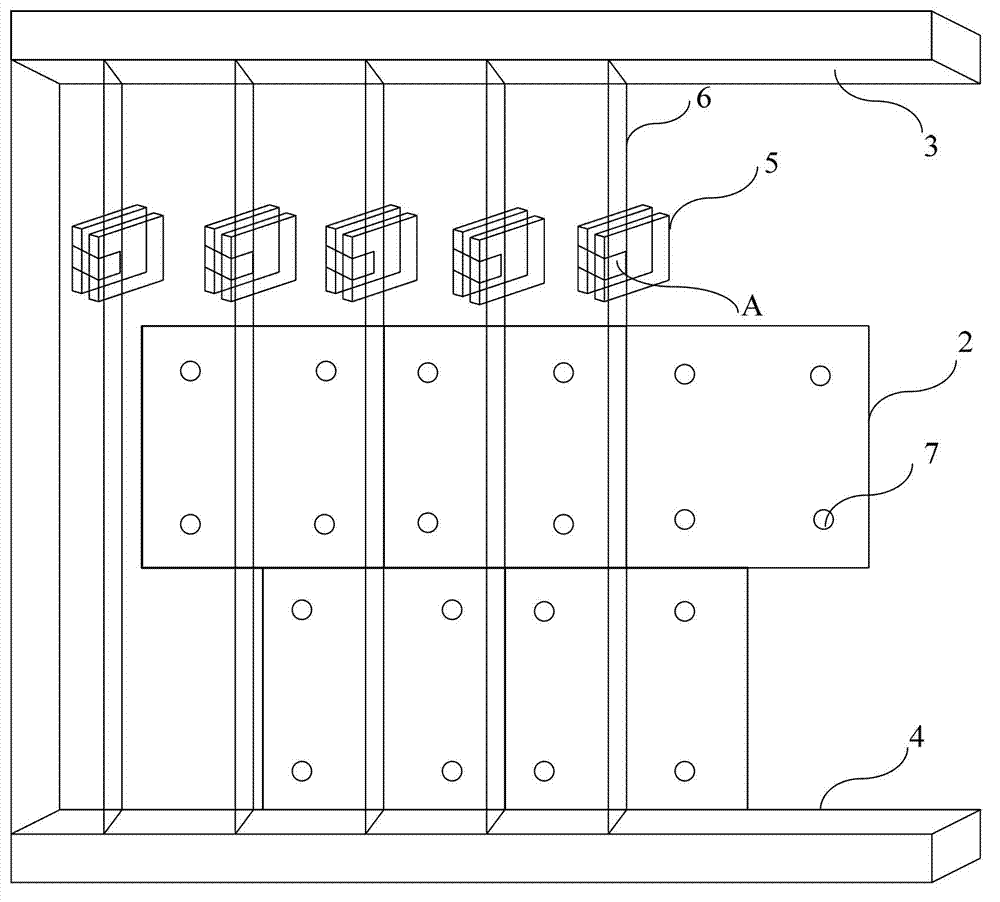

[0022] Such as figure 1 with figure 2 Shown are the structural schematic diagrams of the wallboard system and the inner layer wallboard of the present invention and the structural schematic diagrams of the wallboard system of the present invention and the outer layer wallboard respectively. The wall panel system of the present invention includes wall panels, concrete beams 3 and concrete floor slabs 4 . The wall panels include an inner layer wall panel 1 and an outer layer wall panel 2 . Both the inner wall panel 1 and the outer wall panel 2 are ceramsite concrete panels. Expanded perlite or ceramsite is filled between the inner wallboard 1 and the outer wallboard 2 . The second clip B is fixedly connected between the inner wall panel 1 and the outer wall panel 2 . Bolts 7 are used to fix the inner wallboard 1 and the outer wallboard 2 . The second cli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com