Thrust valve

A technology of thrust and valve casing, applied in the field of pipeline switch valve, can solve the problem of inflexible ball valve rotation, achieve light weight, wide application, and ensure the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

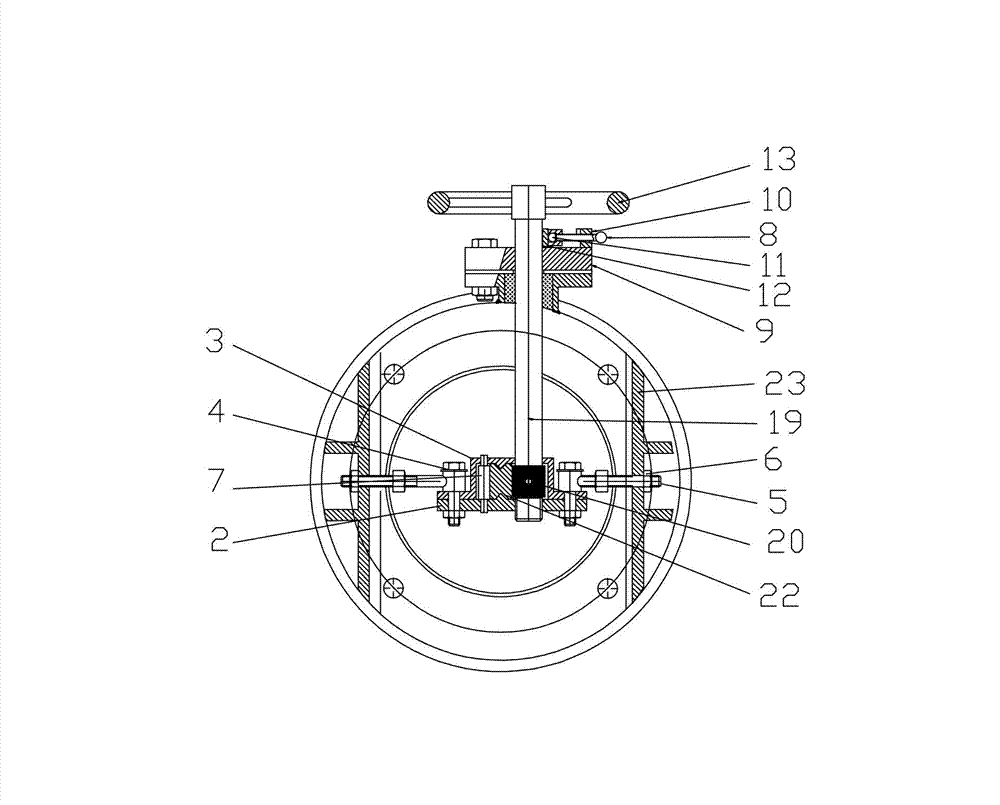

[0026] Such as figure 1 , figure 2 The thrust valve shown has a main structure of a cylindrical valve housing 1, a brake shaft 19 is designed perpendicular to the length of the valve housing, the brake shaft 19 passes through the valve housing 1, and the top of the brake shaft 19 is equipped with For hand wheel 13, the outer periphery of the brake shaft is connected to the valve housing with a sealing seat 9 filled with sealing material; the sealing seat 9 is designed with a positioning nut 10, and a handle 8 is passed through the positioning nut. The end of the handle 8 is The limit ball head 11, a brake pad 12 is installed between the limit ball head 11 and the brake shaft 19, and the positioning nut, handle, limit ball head, and brake pad constitute the brake system; the inner wall of the valve housing 1 is fixed with a support positioning plate 23 The supporting and positioning plate 23 is connected with a positioning rod 5, and the positioning rod 5 is designed with adjust...

Embodiment 2

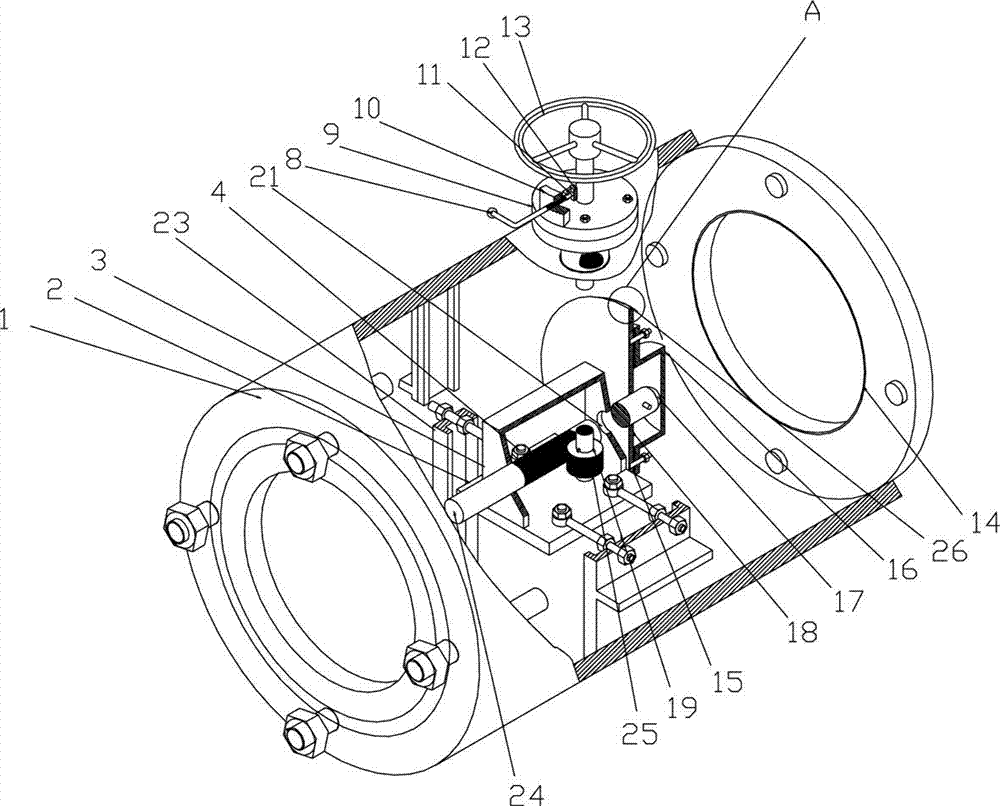

[0029] Such as image 3 , Figure 4 The thrust valve shown has a main structure of a cylindrical valve housing 1, a brake shaft 19 is designed perpendicular to the length of the valve housing, the brake shaft 19 passes through the valve housing 1, and the top of the brake shaft 19 is equipped with For hand wheel 13, the outer part of the brake shaft is connected to the valve housing with a sealing seat 9, and the sealing seat 9 is filled with sealing material; the sealing seat 9 is designed with a positioning nut 10, and a handle 8 is passed through the positioning nut. The end of the handle 8 is The limit ball head 11, a brake pad 12 is installed between the limit ball head 11 and the brake shaft 19, and the positioning nut, handle, limit ball head, and brake pad constitute the brake system; the inner wall of the valve housing 1 is fixed with a support positioning plate 23 The supporting and positioning plate 23 is connected with a positioning rod 5, the positioning rod 5 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com