Improved rotary four-way fluid reversing valve

A rotary and improved technology, used in multi-port valves, valve devices, cocks including cut-off devices, etc., can solve the problems of poor valve core and valve body sealing, difficult manufacturing, pressure drop, etc., to extend the conveying distance, Improve running speed and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

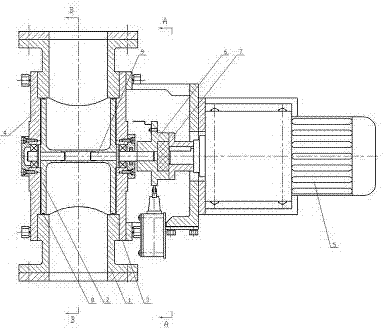

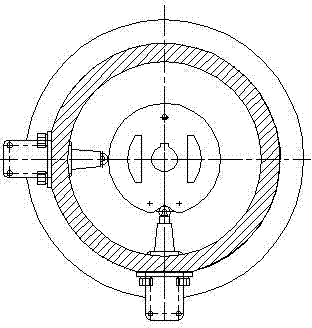

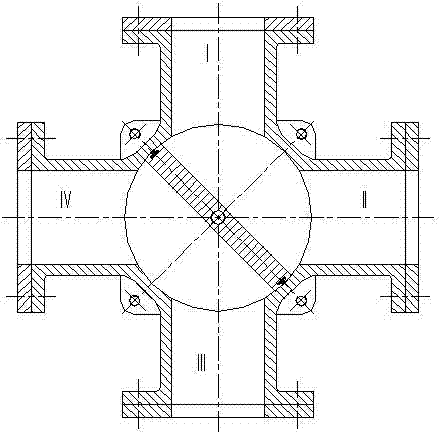

[0022] The structure of the present invention will be described below in conjunction with the accompanying drawings.

[0023] The improved rotary four-way fluid reversing valve of the present invention is mainly composed of a valve body 1, a valve core 2 installed in the valve body, an upper end cover 3 and a lower end cover 4 installed at both ends of the valve body 1 and a driving device 5. The inside of the valve body 1 is a cylindrical hollow cavity, on which there are holes I, II, III and IV communicating with the hollow cavity, and these four holes are symmetrically distributed on the valve body. The driving device 5 is connected with the shaft 9 installed on the valve core 2 through the coupling I6 and the coupling II7 and drives the valve core 2 to rotate. The improvement is that the valve core 2 is designed as a cylinder with an "I"-shaped cross section, and "U"-shaped grooves are opened on the upper and lower cylindrical surfaces, and the sealing ring 8 can be instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com