Ash-discharging and air-locking system for air cooling dry slag extractor

A slag discharger and dry-type technology, which is applied in the field of automatic ash release and air lock system, can solve the problems of blowing out coal ash and affecting the operation of the dry slag machine, and achieve the effect of reducing air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

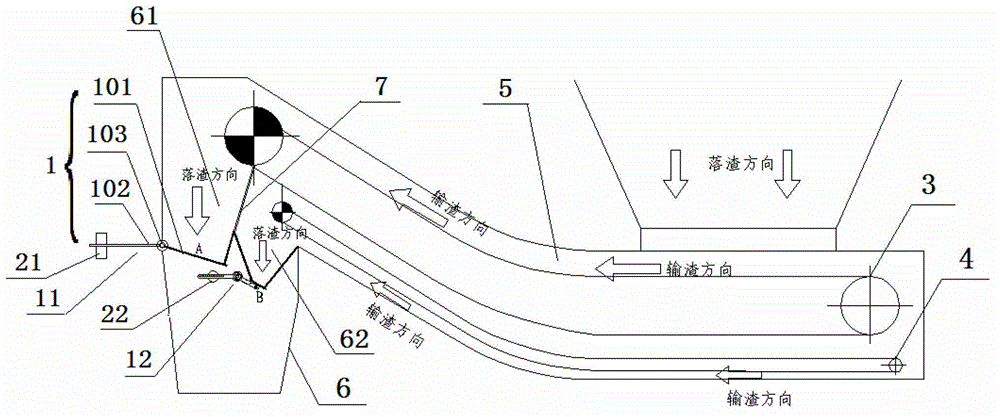

[0038] Such as figure 1As shown, the air-cooled dry slag machine automatic ash lock system provided by the present invention includes: an air lock device 1, a driving mechanism 2, a steel belt conveying slag discharging device 3 and a steel belt conveying slag discharging device 3 The cleaning chain ash discharge device 4 below, the steel belt conveying slag discharge device 3 and the cleaning chain ash discharge device 4 are all placed in a closed box 5, and the discharge of the steel belt conveying slag discharge device 3 and the cleaning chain ash discharge device 4 There is a discharge hopper 6 at the end, and the driving mechanism 2 is arranged on the outside of the discharge hopper 6, and it is linked with the air lock device 1 to control the discharge of ash in the discharge hopper 6; 7. The material distribution partition 7 divides the hopper 6 into two independent slag channels, namely the first slag channel 61 and the second slag channel 62. The first slag channel 61...

Embodiment 2

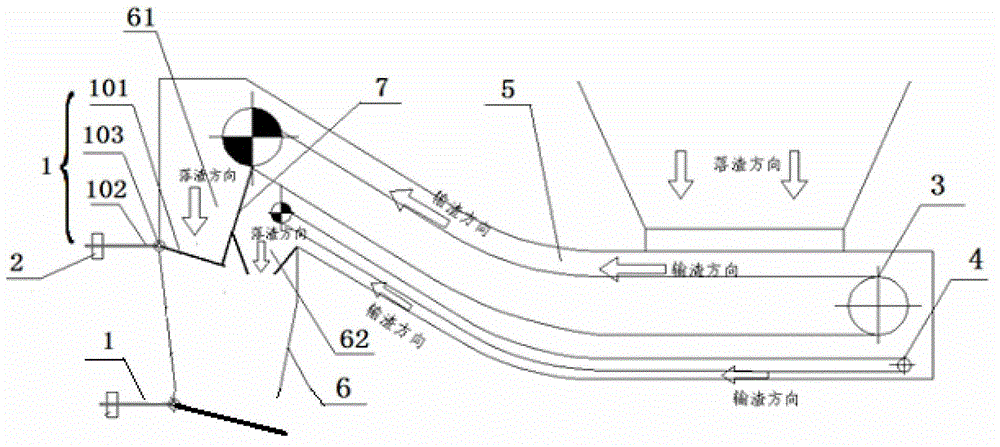

[0042] Such as figure 2 As shown in the structure, the difference from Example 1 is that a third air lock device 13 and a third drive mechanism 23 are provided at the outlet end of the lowermost end of the discharge hopper 6, and the first slag channel 61 is provided with a The structures of the first air lock device 11 and the first driving mechanism 21 are the same as those of the air lock device and the driving mechanism described in Embodiment 1, and will not be repeated here.

Embodiment 3

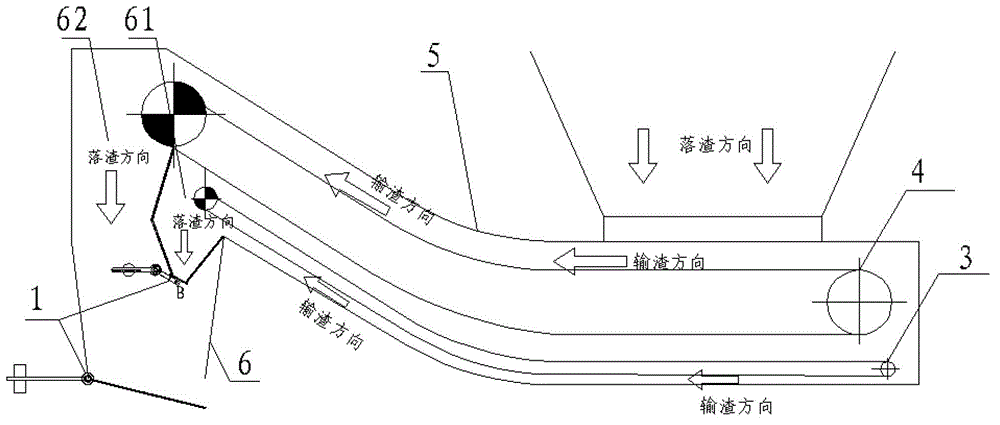

[0044] Such as image 3 As shown in the structure, the difference from Embodiment 1 is that a third air lock device 13 and a third drive mechanism 23 are provided at the outlet end of the lowermost end of the discharge hopper 6, and a second slag channel 62 is provided with The structure of the second air lock device 12 and the second drive mechanism 22 is the same as that of the air lock device and the drive mechanism described in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com