Method for recovering condensed fluid of glyphosate synthesis solution

A glyphosate and drying technology, which is applied in drying solid materials, lighting and heating equipment, drying, etc., can solve the problems of raw material waste, low production capacity, and low yield, and achieve the reduction of steam and other losses and the reduction of powder Generation, the effect of high-grade product rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

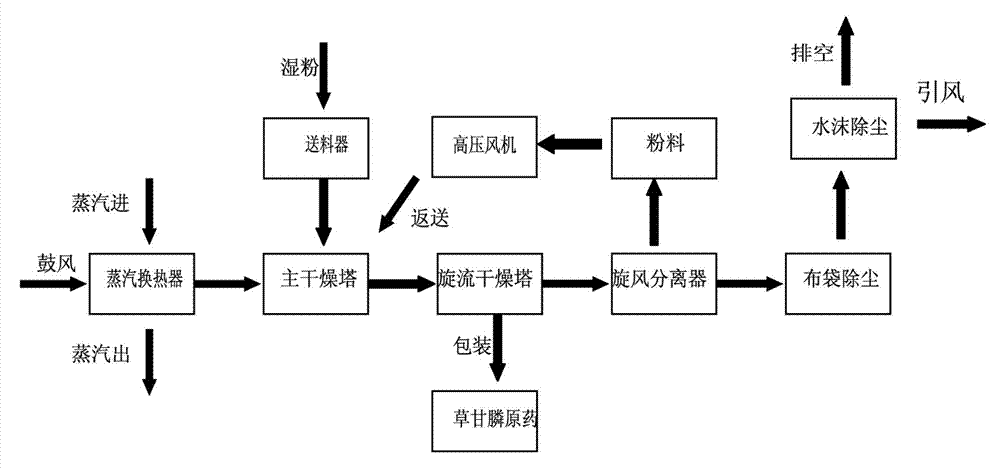

[0009] The heat of the main drying tower comes from the steam heat exchanger, and is blown into the main drying tower through a blower to dry the wet glyphosate powder sent by the feeder, and the wet glyphosate powder is blown by the hot cyclone in the main drying tower Begin blowing into the cyclone drying tower, and discharge the material at the bottom of the cyclone drying tower to obtain the qualified glyphosate technical medicine. The hot cyclone at the top of the tower is sucked into the glyphosate powder with low content and high-grade product rate. To the cyclone separator. The glyphosate powder in the cyclone separator is fed into the main drying tower through a fan, and is mixed and dried with the wet glyphosate powder again, and recycled and recycled to improve the recovery rate of the original medicine. The pressure of the cyclone separator is controlled at -2.5~-1.5KPa. The glyphosate powder is obtained by discharging the material at the bottom of the cyclone separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com