Five-grain fen-flavor liquor and preparation method thereof

The technology of a fragrant-flavor liquor and a production method is applied in the preparation of alcoholic beverages and other directions, and can solve the problems of low flavor, insufficient sweetness and mellowness, and low alcohol yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

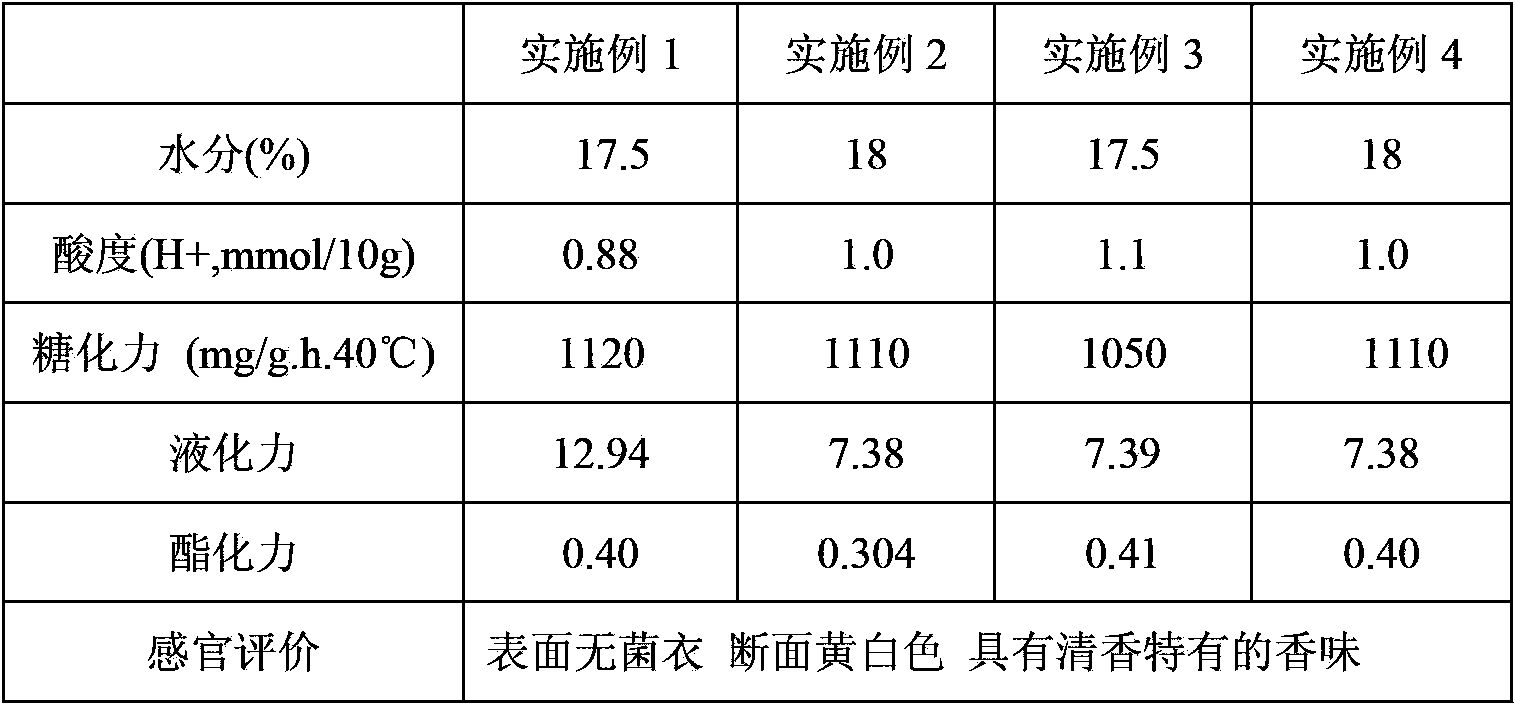

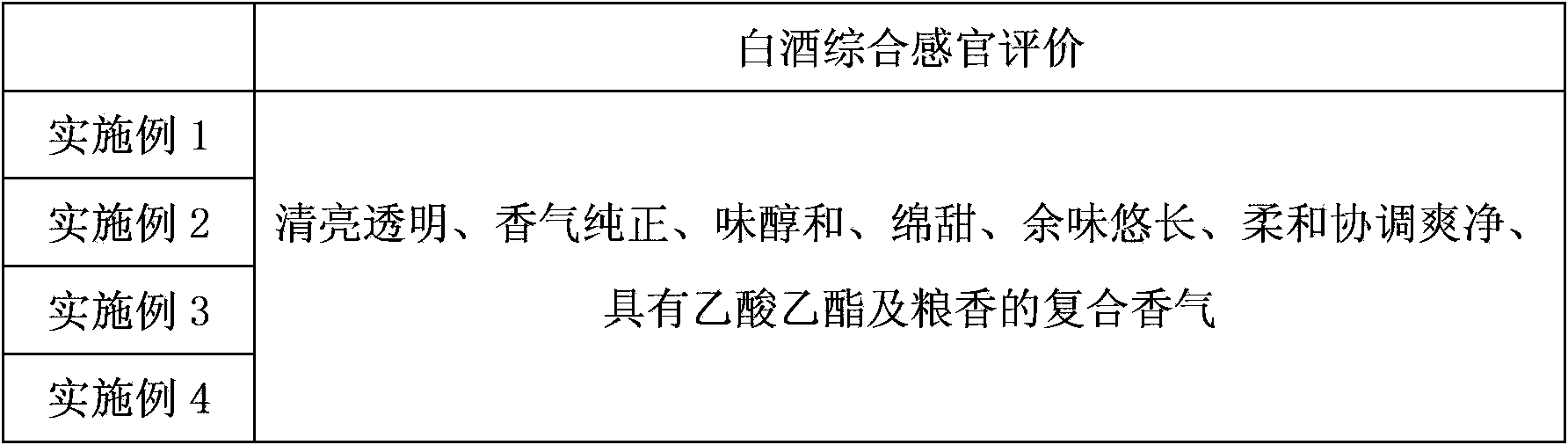

Examples

Embodiment 1

[0109] 1. Prepare stubble daqu

[0110] 1) Prepare Daqu raw materials according to the following weight ratio (×100kg)

[0111] Barley 4 Peas 3

[0112] Wheat 2 Bran 1

[0113] 2) Crushing of raw materials

[0114] After barley, pea and wheat are dedusted and impurity removed, they are crushed into mixed fine powder of barley, pea and wheat with a steel mill, wherein the weight of the mixed fine powder of barley, pea and wheat passing through a 20 mesh sieve is the same as that of the koji-making raw material. The ratio of total weight is 30:100; then add bran and stir evenly to obtain Daqu mixed powder;

[0115] 3) Prepare bent billet

[0116] Add water to the mixed powder of Daqu and stir evenly, and use a koji press (Shangqiu Yugong Machinery Co., Ltd.) to press it into a koji billet, wherein the ratio of the weight of water added to the mixed powder of Daqu to the total weight of raw materials for making koji The ratio is 35:100; the temperature of the water is 25°C; ...

Embodiment 2

[0156] 1. Prepare stubble daqu

[0157] 1) Prepare raw materials according to the following weight ratio (×100kg)

[0158] Barley 5 Peas 2

[0159] Wheat 1 Bran 1

[0160] 2) Crushing of raw materials

[0161]Except that the ratio of the weight of barley, pea, and wheat mixed fine powder passing through 20 mesh sieves to the total weight of koji raw materials is 25:100, all the other are the same as in Example 1;

[0162] 3) Prepare bent billet

[0163] Except that the ratio of the weight of the added water to the total weight of the koji-making raw materials is 34:100; the temperature of the water is 33°C, the rest are the same as in Example 1;

[0164] 4) Fermentation treatment

[0165] In addition to the treatment time of "upper mildew" for 2 days, the temperature of the fermentation room is 33°C (dry bulb), and the temperature difference between dry and wet bulbs is 3°C; The time is 1 day, the temperature of the fermentation room is 28°C, and the temperature differen...

Embodiment 3

[0176] 1. Prepare stubble daqu

[0177] 1) Prepare raw materials according to the following weight ratio (×100kg)

[0178] Barley 3 Peas 2

[0179] Wheat 2 Bran 1

[0180] 2) Crushing of raw materials

[0181] Except that the ratio of the weight of barley, pea, and wheat mixed fine powder passing through 20 mesh sieves to the total weight of koji raw materials is 35:100, all the other are the same as Example 1;

[0182] 3) Prepare bent billet

[0183] Except that the ratio of the weight of the added water to the total weight of the koji-making raw materials is 36:100; the temperature of the water is 16°C, the rest are the same as in Example 1;

[0184] 4) Fermentation treatment

[0185] In addition to the treatment time of "upper mildew" which is 2 days, the temperature of the fermentation room is 32°C (dry bulb), and the temperature difference between dry and wet bulbs is 1°C; The time is 3 days, the temperature of the fermentation room is 24°C (dry bulb), and the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com