Method for valuing construction period wind load of ultra-large cooling tower

A wind load and cooling tower technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of separating the final working conditions of uncooled towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0117] The method for obtaining the value of the wind load during the construction period of the ultra-large cooling tower involved in this embodiment includes the following steps:

[0118] 1) Establish a wind load stationary binomial stochastic process model;

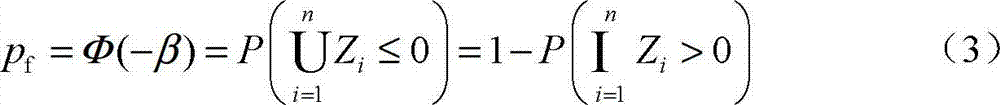

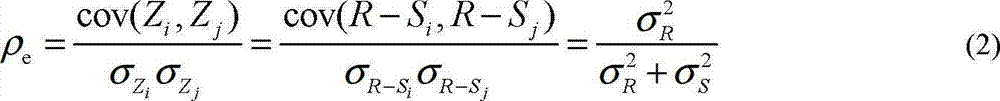

[0119] 2) According to the characteristics of the wind load stationary binomial stochastic process model, use the period analysis method of structural reliability to establish the relationship between the structural design reference period and each period in between, and the construction period and the reliability relationship between each period in between, forming the period Relational expressions and reliability relational expressions;

[0120] 3) Starting from the fact that the structural resistance in the construction period is proportional to the design reference period, by solving the relational expression in step 2), the ratio of the standard value of wind load during the construction period to the standard val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com