Electric heating device

An electric heating device and electric heating wire technology, applied in the direction of the shape of the heating element, can solve the problems of easy aging and falling off of the insulating layer, inability to heat up quickly, and low thermal conductivity, and achieve the effects of strong hardness, low cost, and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

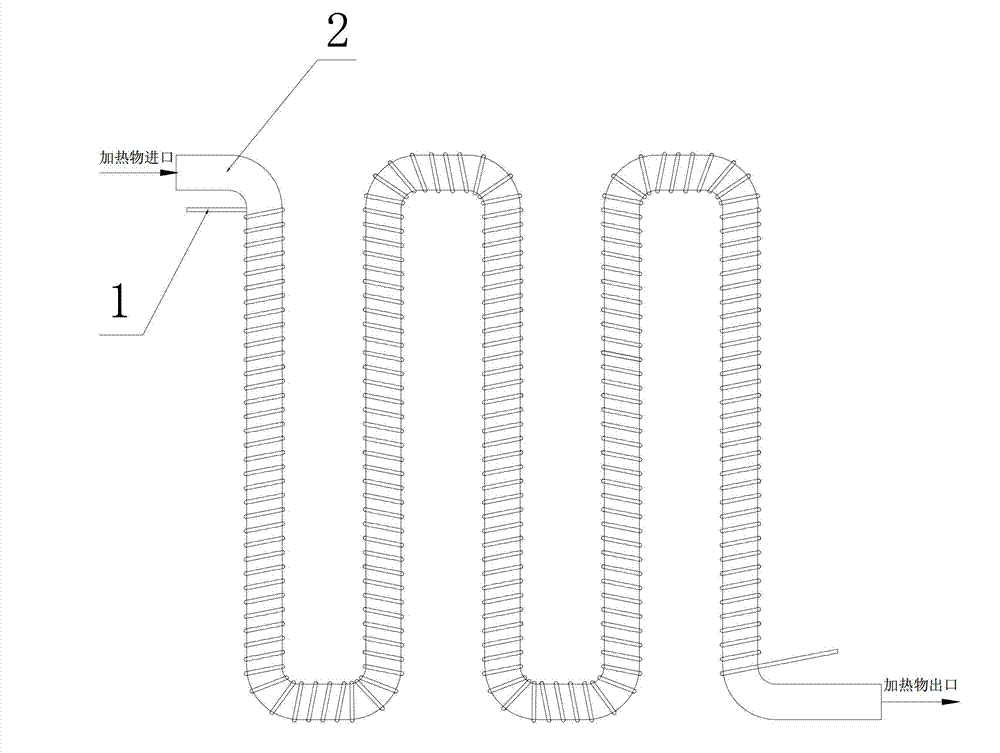

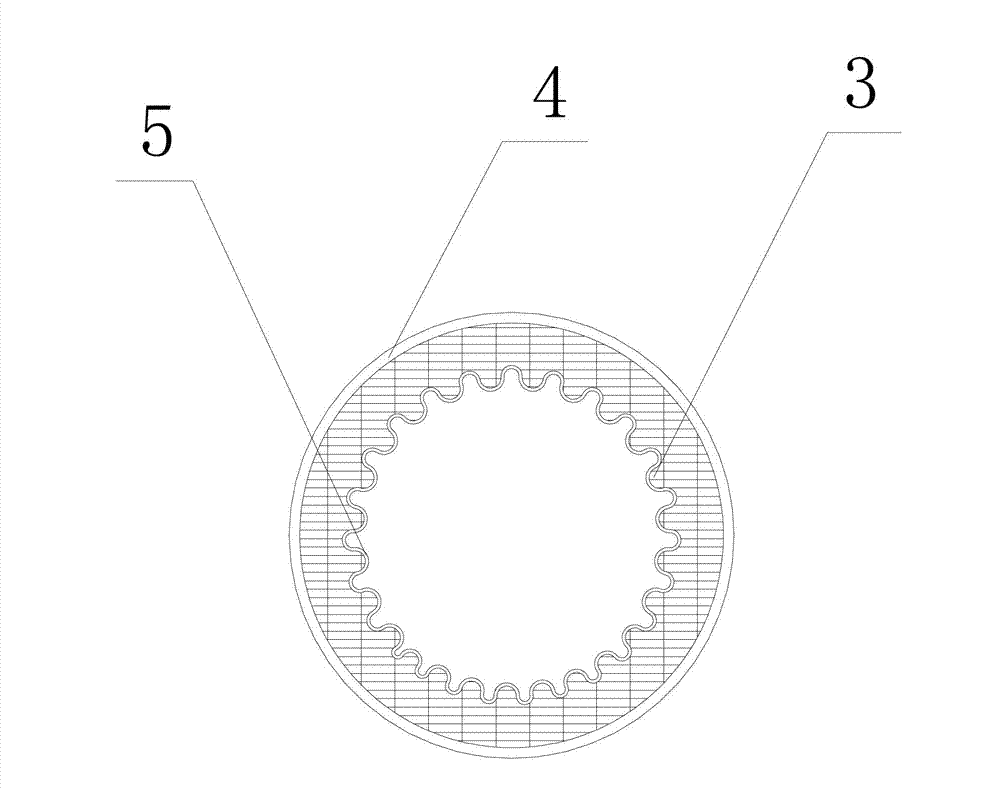

[0013] Such as figure 1 , figure 2 As shown, an electric heating device according to the present invention includes a heat pipe and an electric heating wire 1, the electric heating wire 1 is spirally wound on the outer wall of the heat pipe, the heat pipe is an aluminum alloy pipe 2, and the aluminum alloy pipe 2 has The copper tube has the advantages of good thermal conductivity, easy ductility, and low cost. The outer wall surface of the aluminum alloy tube 2 is provided with an outer sulfuric acid anodized film 4 . Since the sulfuric acid anodized film has the characteristics of insulation and high heat conduction efficiency, the electric heating wire 1 can be directly contacted with the aluminum alloy tube 2 for heating, thereby improving the heating energy efficiency. At the same time, the sulfuric acid anodized film has high hardness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com