Dosing actuator for an aerosol container with interchangeable tubes

A hose and adapter technology, applied in liquid distribution, liquid injection devices, packaging, etc., can solve problems such as unusable, high production cost, and complicated design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

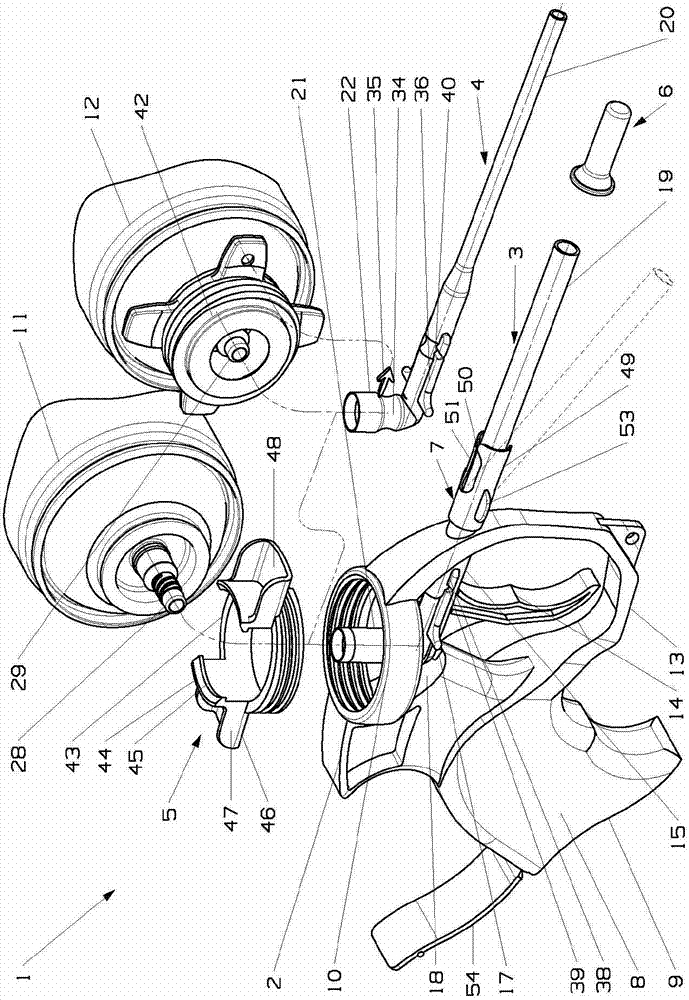

[0029] figure 1 Shown is an assembly drawing of the dosing device comprising housing 2, exchangeable hoses (3, 4), adapter 5, control nozzle 7, cap 6, bottle 12 with fasteners and without fasteners 11 pieces of bottles.

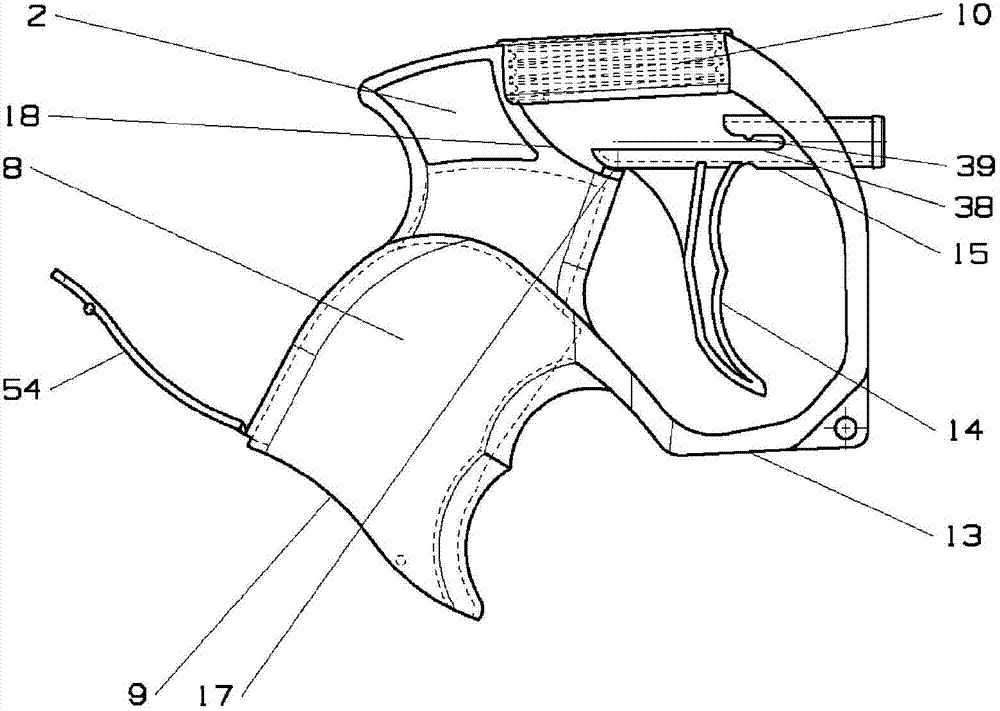

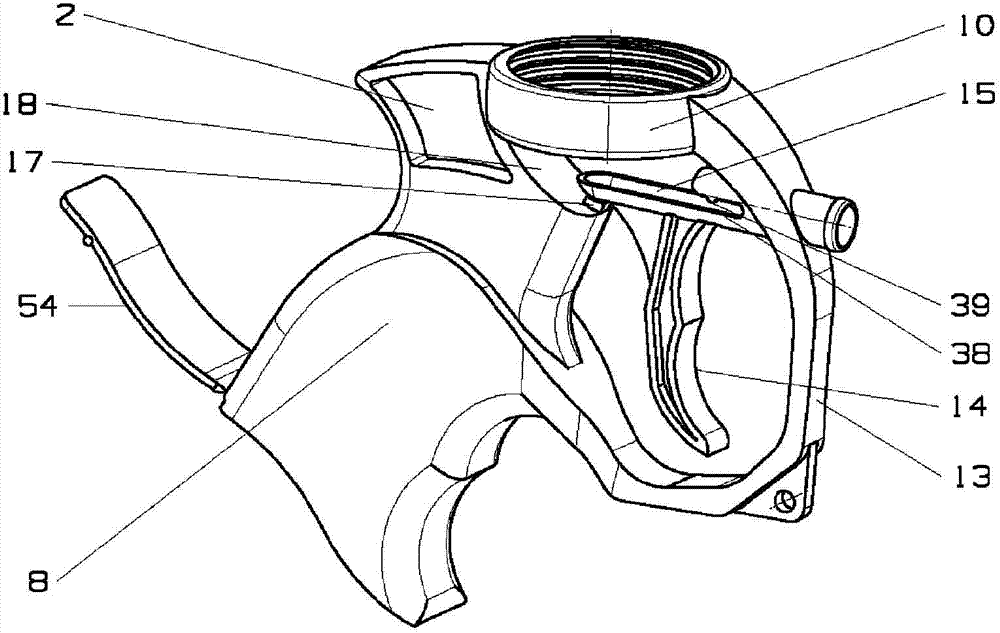

[0030] The replaceable hoses (3, 4) enter the steam guide groove 15. Next, slide and position the mounting rods (36, 37) in the guide slots 38 along the rails 18 and the bottom of the nozzles (21, 22) and attach the replaceable hose using the fasteners 39 that go into the recesses (40, 41). fixed in the steam guide groove 15, such as figure 1 , 4 , 6, and 12. Remove the hose from the housing in reverse order. Said bottle 12 is installed on the dosing device by threaded connection. The bottle 11 is secured to the dosing device using an adapter 5 . Then, the replaceable hose 3 and the bottle 11 are used together with the replaceable hose 4 and the bottle 12, as figure 1 , 10 , 11 shown. After installing the bottle on the shell, the bottle mouth (28, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com