Bonding lining cloth production line

A fusible interlining and production line technology, which is applied in interlining production and double-point fusible interlining production, can solve the problems of poor fusible interlining effect, affecting the quality of interlining, and low drying efficiency, achieving less manual labor and improving Drying speed, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

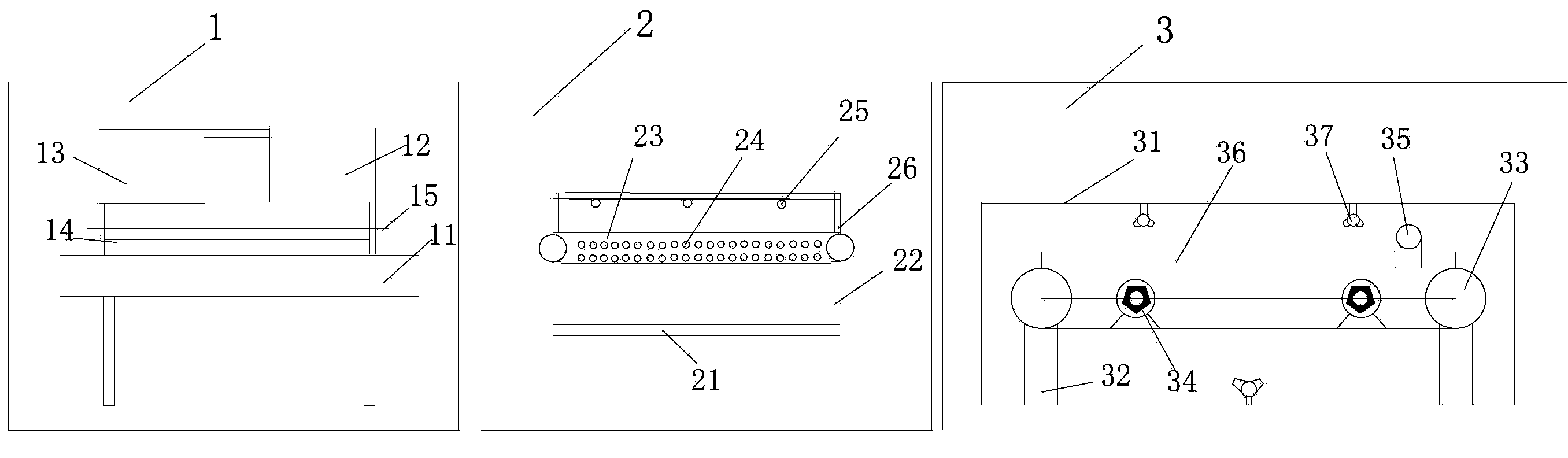

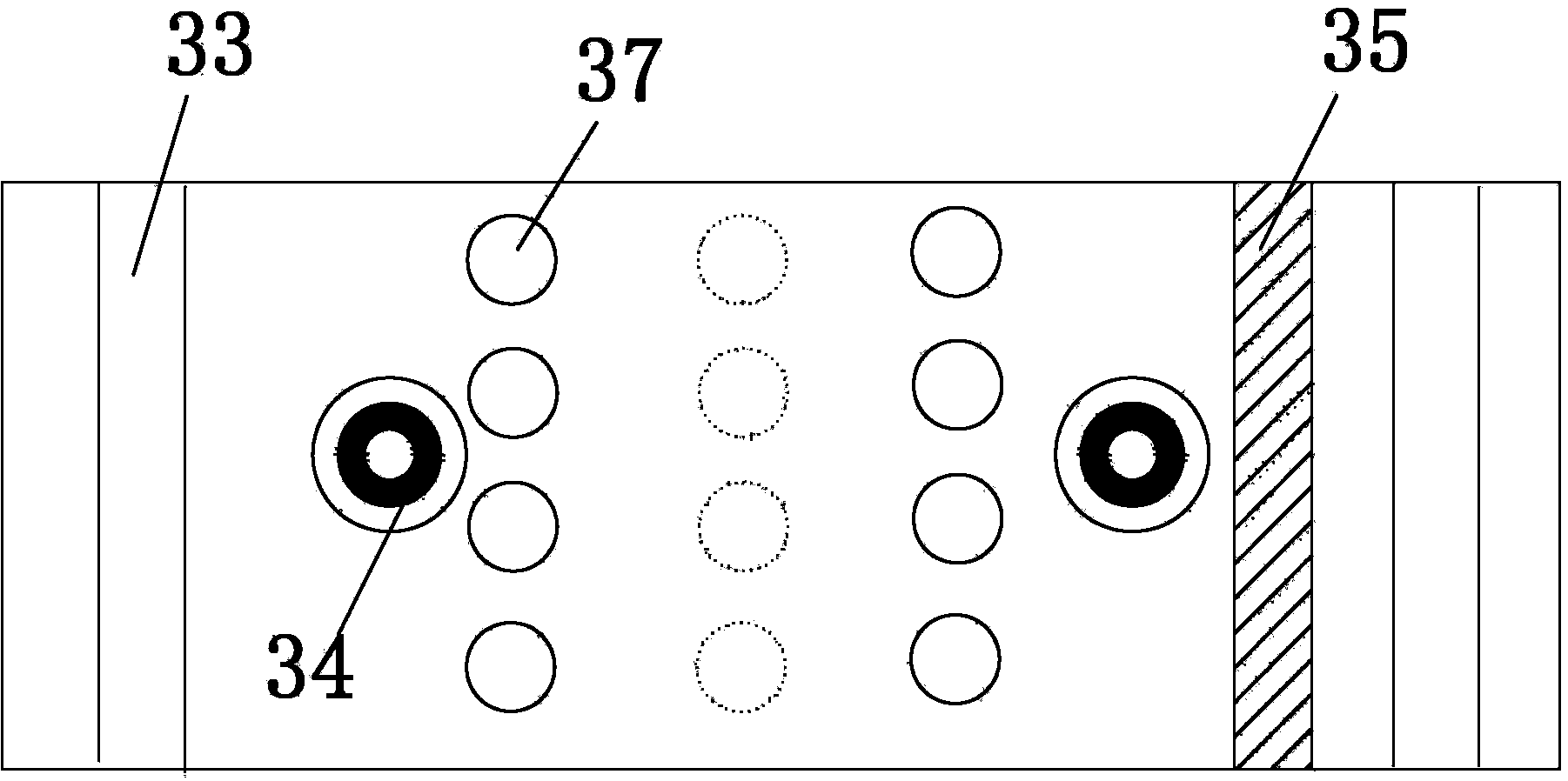

[0017] refer to figure 1 and figure 2 , the fusible interlining production line of the present invention includes a dispensing and powdering device 1, a cylinder spraying device 2 and a drying and setting device 3 in sequence.

[0018] Described dispensing and powdering device 1 comprises frame 11, dispensing mechanism 12, powdering mechanism 13, heating and curing device, and described dispensing mechanism 12 and powdering mechanism 13 are all positioned at the top of frame 11, and described dispensing Mechanism 12 is located on the right side of powder feeding mechanism 13, and the heating and curing device is located between the dispensing mechanism 12 and the frame 11. The heating and curing device includes an infrared tube 14 and an iron plate 15, and the infrared tube 14 is located on the iron plate. 15, the distance between the infrared tube 14 and the iron plate 15 is 10 cm, and the distance between the dispensing mechanism 12 and the heating and curing device is 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com