Fire-extinguishing agent gas pressure network monitoring system of gas fire-extinguishing system bottle unit

A technology of fire extinguishing system and gas pressure, applied in fire rescue and other fields, can solve problems such as time-consuming and laborious inspection, failure to find problems in time, losses, etc., and achieve good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

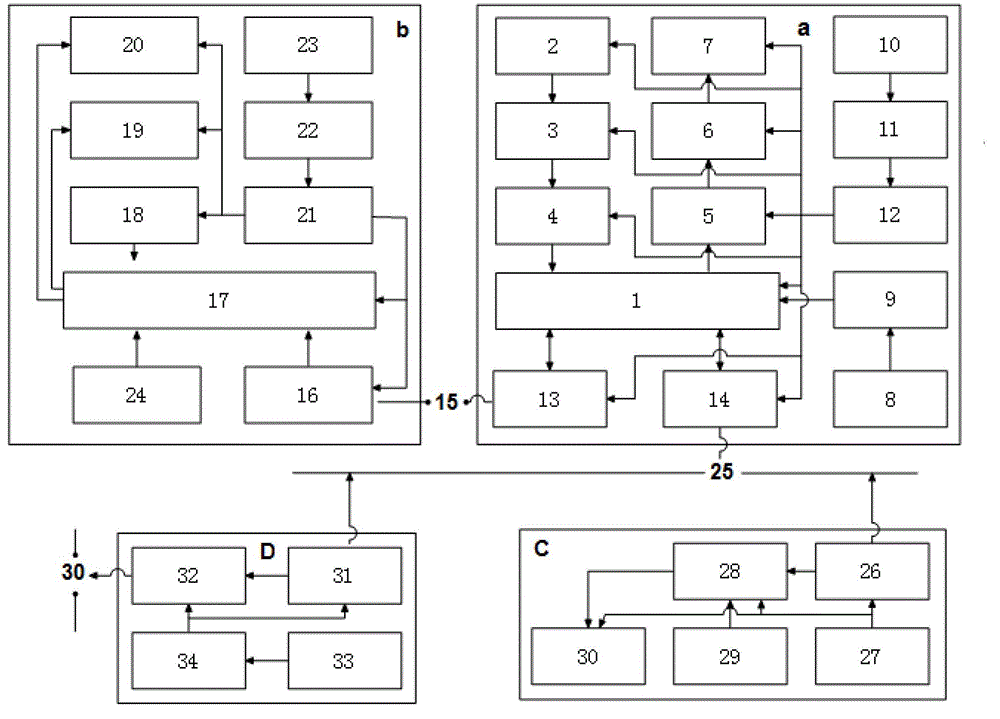

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0036] overall system design

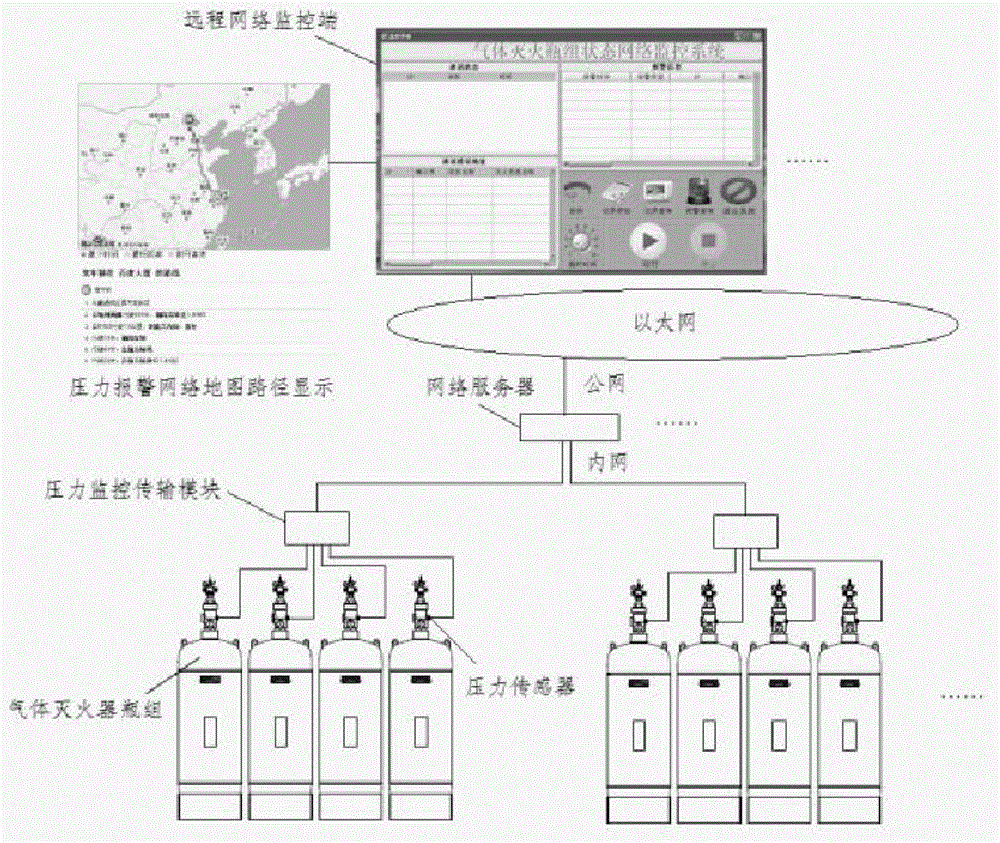

[0037] The gas fire extinguishing bottle network monitoring system is mainly composed of three parts: the local module of the gas fire extinguishing system bottle group, network transmission and remote monitoring, such as figure 1 shown.

[0038]The local module of the gas fire extinguishing system bottle group consists of a gas fire extinguishing system bottle group, a pressure sensor (such as a pressure switch) and a pressure monitoring transmission module. The pressure sensor is connected to the cylinder group of the gas fire extinguishing system, and the signal end of the pressure sensor is connected to the pressure monitoring transmission module, and the pressure condition of the fire extinguisher cylinder group is fed back to the pressure monitoring transmission module at any time. The pressure monitoring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com