Production system for processing of film-coated building template

A technology for building templates and production systems, applied in wood processing appliances, household components, other household appliances, etc., can solve the problems of difficult to master consistent quality standards, difficult to meet production needs, difficult to achieve standardization, etc., to ensure the quality of grooving and Standardization, improving labor productivity, ensuring quality and the effect of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

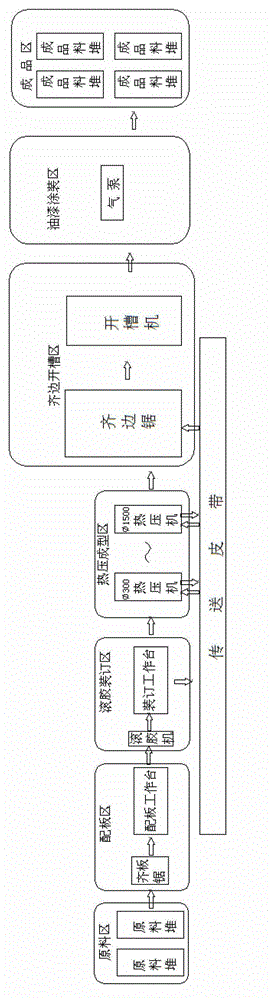

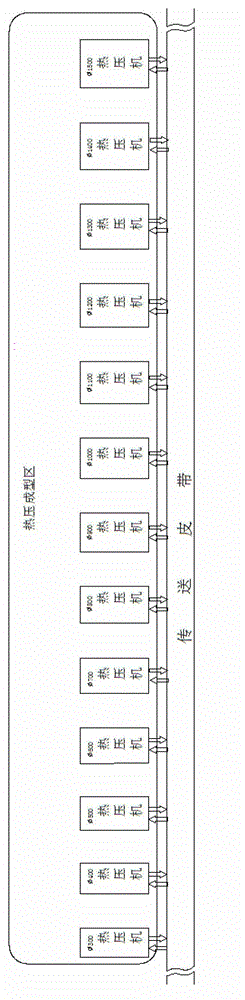

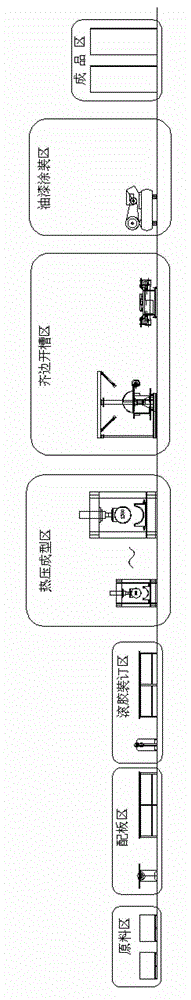

[0038] A kind of clear water film-covered building template processing and production system, such as Figure 1 to Figure 4 As shown, it includes the raw material area, board matching area, rubber binding area, hot pressing forming area, edge-aligning slotting area, paint coating area and finished product area set in sequence. The board matching area, rubber binding area, Conveyor belts are installed on one side of the thermoforming area and the edge-aligned slotting area, and each process area is specifically as follows:

[0039] In the raw material area, a plurality of groups of raw material stacks of stacked plate raw materials are stacked at intervals;

[0040] The board matching area is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com