Adhesive for solar back panel and preparation method thereof

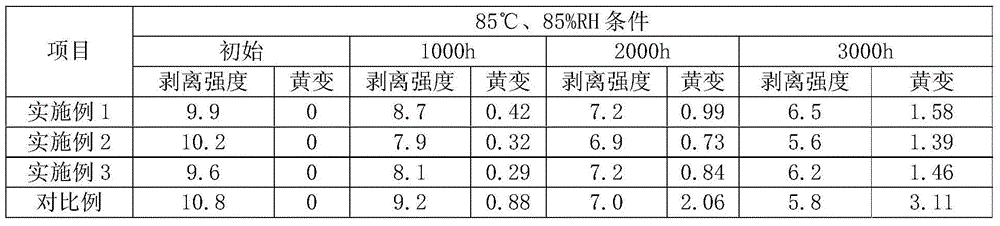

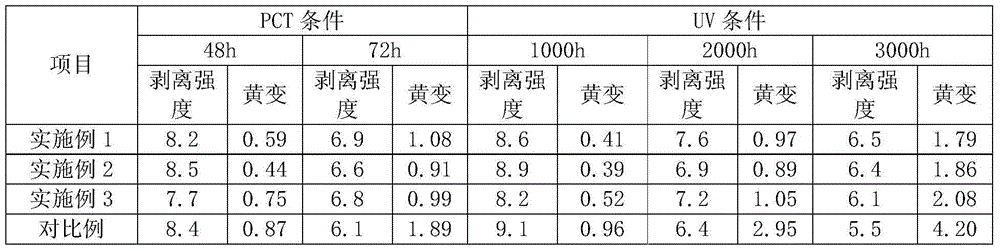

A technology for solar backsheets and adhesives, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem that the yellowing resistance of adhesives cannot meet the use requirements, high solvent content in adhesives, and unfavorable environmental protection and other problems, to achieve the effect of reducing the amount of solvent, high peel strength retention rate, and low yellowing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention also discloses a preparation method of an adhesive for a solar back panel, comprising the following steps:

[0045] a. Synthesis of polyester polyols:

[0046] a1 After adding isophthalic acid, sebacic acid, azelaic acid and octadecanedibasic fatty acid into the reactor, add neopentyl glycol, hexanediol and butylene glycol into the reactor, and stir under nitrogen protection And be heated up to 220 ℃ to react;

[0047] a2 Stop nitrogen flow and carry out polycondensation reaction with products with an acid value ≤ 20mgKOH / g, raise the temperature of the reactor to 230°C, and gradually vacuumize until the vacuum degree is -0.09—-0.1MPa, and the vacuum reaction time is 2 -4h;

[0048] a3 obtaining a polyester polyol with a molecular weight of 5000-10000, a hydroxyl value of 15-30 mgKOH / g, and an acid value of ≤2 mgKOH / g;

[0049] b. Preparation of adhesive system:

[0050] The polyester polyol of b1 step a3 is the main agent, adding an organic solvent to...

Embodiment 1

[0055] The solar backboard adhesive of this embodiment, the adhesive is prepared by weight percentage from polyester polyol, isocyanate curing agent, organic solvent and auxiliary agent, and the solid content is 45%;

[0056] In this example, the molecular weight of the polyester polyol is 10000, which ensures that the system still has very good processing fluidity when the present invention is used at a high solid content; the hydroxyl value is 20 mgKOH / g, and the acid value is ≤ 2 mgKOH / g;

[0057] In this embodiment, the isocyanate curing agent is an aliphatic or alicyclic isocyanate compound or its multimer; it greatly improves and ensures the heat and humidity resistance and yellowing performance of the adhesive system;

[0058] In the present embodiment, the isocyanate curing agent is hexamethylene diisocyanate, hexamethylene diisocyanate trimer or isophorone diisocyanate; the present embodiment selects hexamethylene diisocyanate trimer, of course , choose above-mentione...

Embodiment 2

[0078] The adhesive for the solar backboard of this embodiment, the adhesive is prepared by weight percentage from polyester polyol, isocyanate curing agent, organic solvent and auxiliary agent, and the solid content is 60%;

[0079] Wherein, by weight: polyester polyol: isocyanate curing agent = 5:1—15:1; in this embodiment, it is 5:1;

[0080] In this example, the molecular weight of the polyester polyol is 5000, which ensures that the system still has very good processing fluidity when the present invention is used at a high solid content; the hydroxyl value is 15 mgKOH / g, and the acid value is ≤2 mgKOH / g;

[0081] In this embodiment, the isocyanate curing agent is an aliphatic or alicyclic isocyanate compound or its multimer; it greatly improves and ensures the heat and humidity resistance and yellowing performance of the adhesive system;

[0082] In this embodiment, the isocyanate curing agent is hexamethylene diisocyanate, hexamethylene diisocyanate trimer or isophorone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com