Auxiliary device used for oxygen lance maintenance pressure test

An auxiliary device and oxygen lance technology, applied in the field of iron and steel smelting, can solve problems affecting other work in the workshop, inconvenient operation for workers, and low work efficiency, and achieve the effects of reducing frequent use, reducing labor intensity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

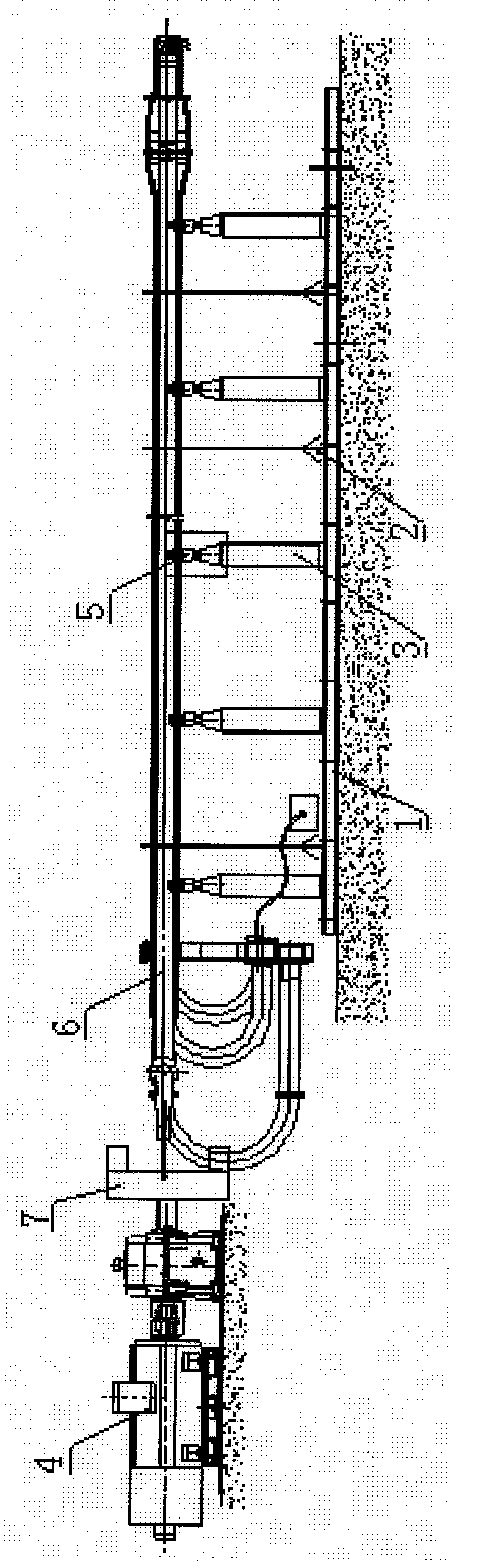

[0017] See figure 1 , an auxiliary device for oxygen lance maintenance and pressure testing, mainly including a maintenance platform 1, a roller base 3, and an oxygen lance rotating device 4, the roller base 3 is arranged on the maintenance platform 1, and the roller base is set according to the length of the oxygen lance The roller group 5 is arranged on the upper part of the roller base 3, and the oxygen lance rotating device 4 is arranged at a position close to one end of the maintenance platform 1. During maintenance operation, the oxygen lance 6 is placed on the drum 5.5 on the upper part of the roller set 5, and the tail of the oxygen lance 6 is connected with the oxygen lance rotating device 4.

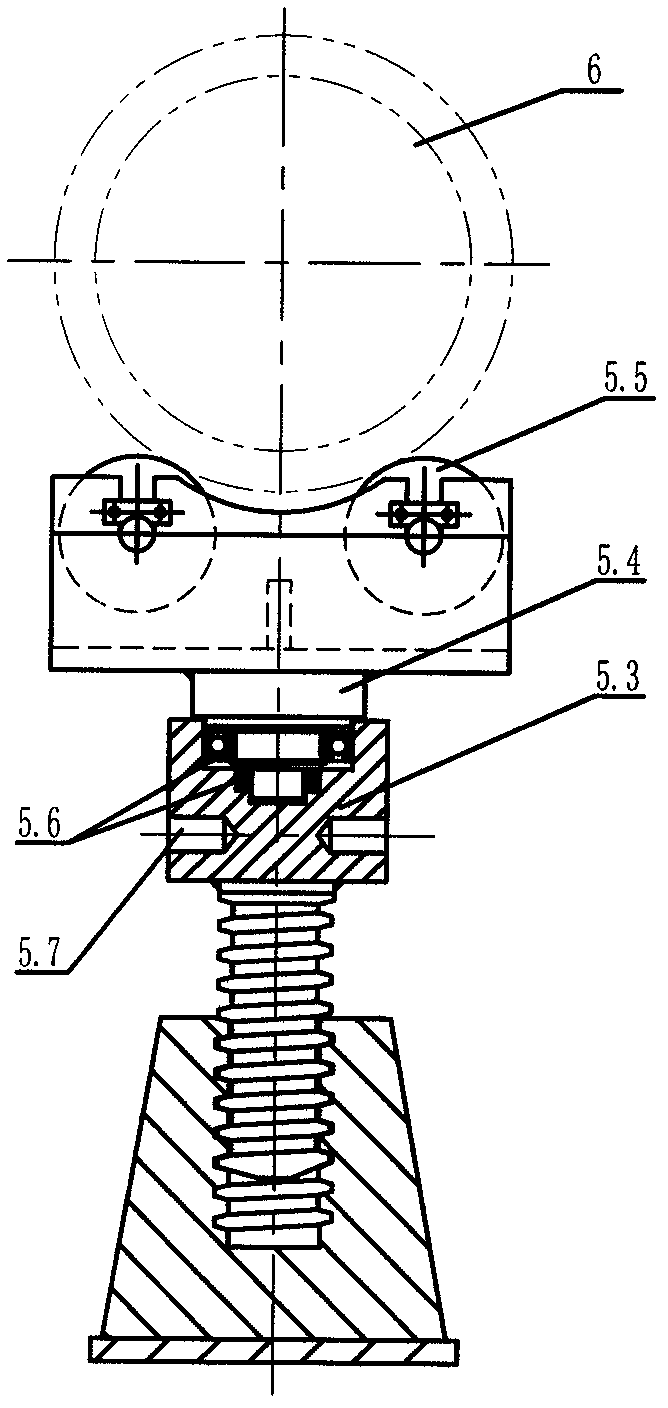

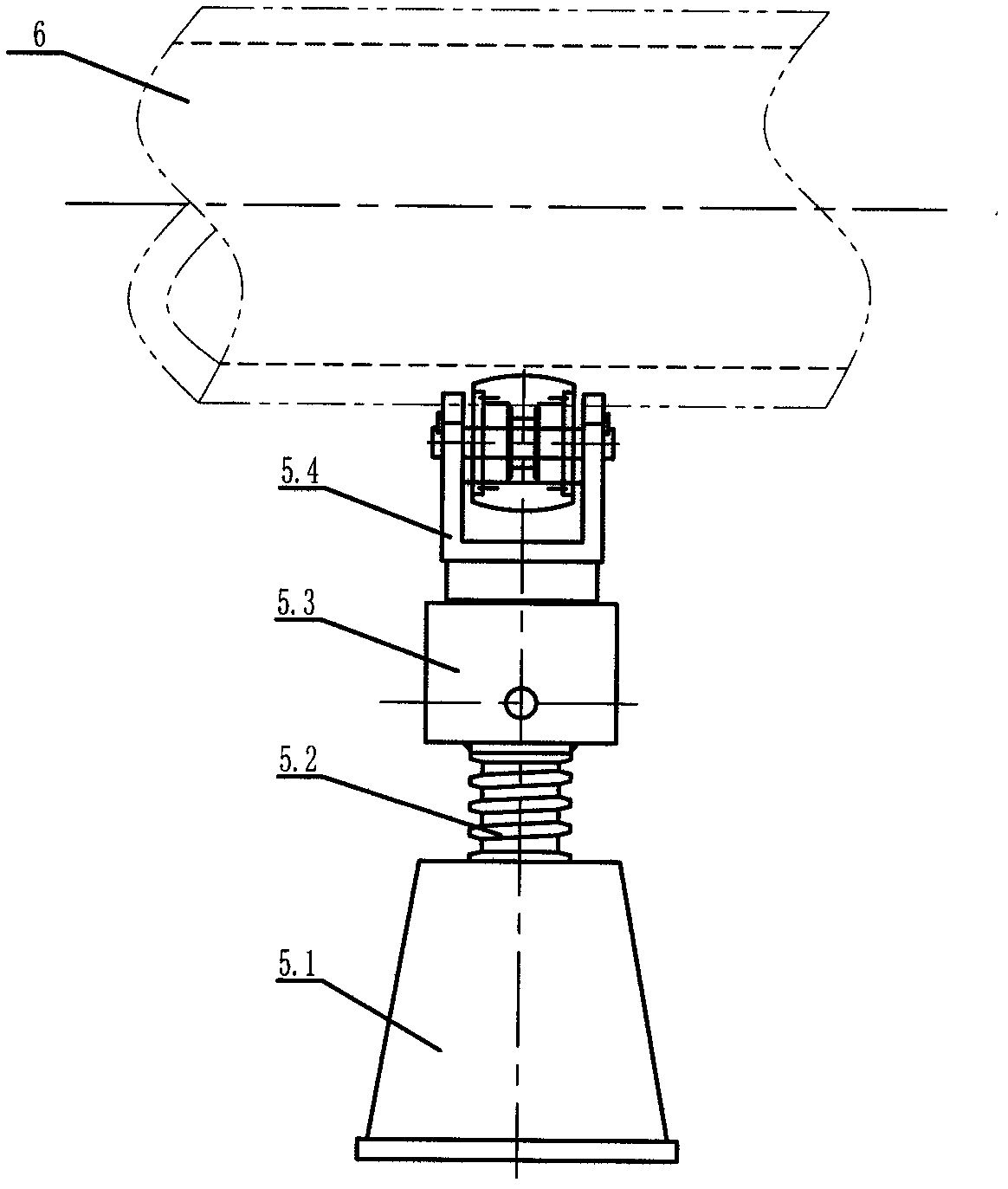

[0018] See figure 2 , image 3 , the roller group 5 is composed of a base 5.1, a lead screw 5.2, a bracket 5.3, a rotating seat 5.4, and a drum 5.5. The bottom of the lead screw 5.2 is screwed to the base 5.1, and the bracket 5.3 is fixedly connected to the top of the lead s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com