A power heat pipe central air conditioner

A central air conditioner and power heat pipe technology, applied in the field of air conditioning and refrigeration, can solve problems such as excessive power consumption, increase the pressure difference between the front and back of the compressor, and excessive power consumption, so as to reduce energy consumption, improve heat transfer efficiency, and ensure service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

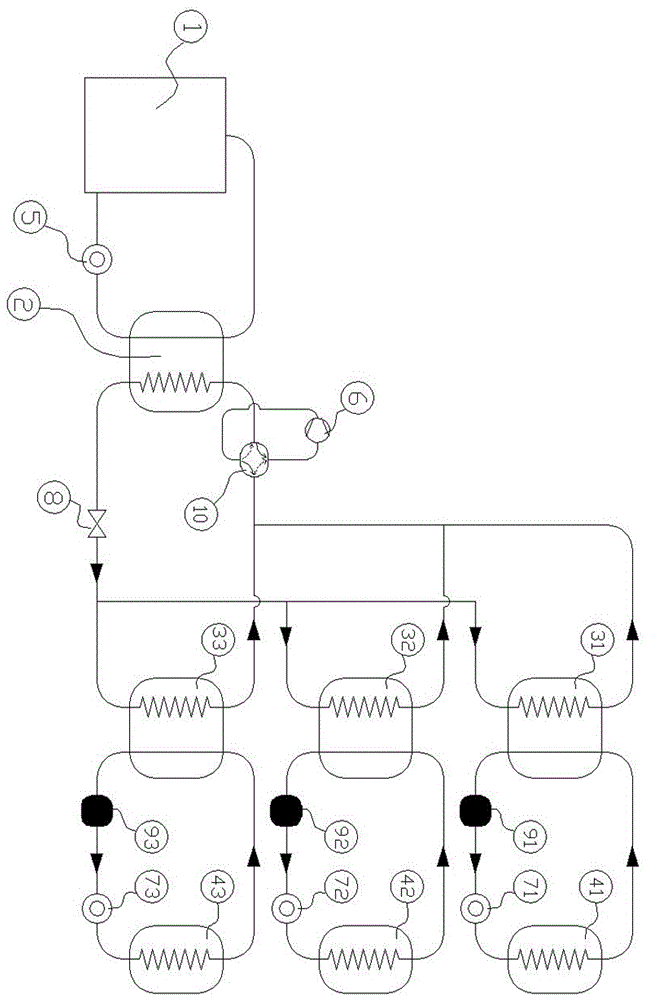

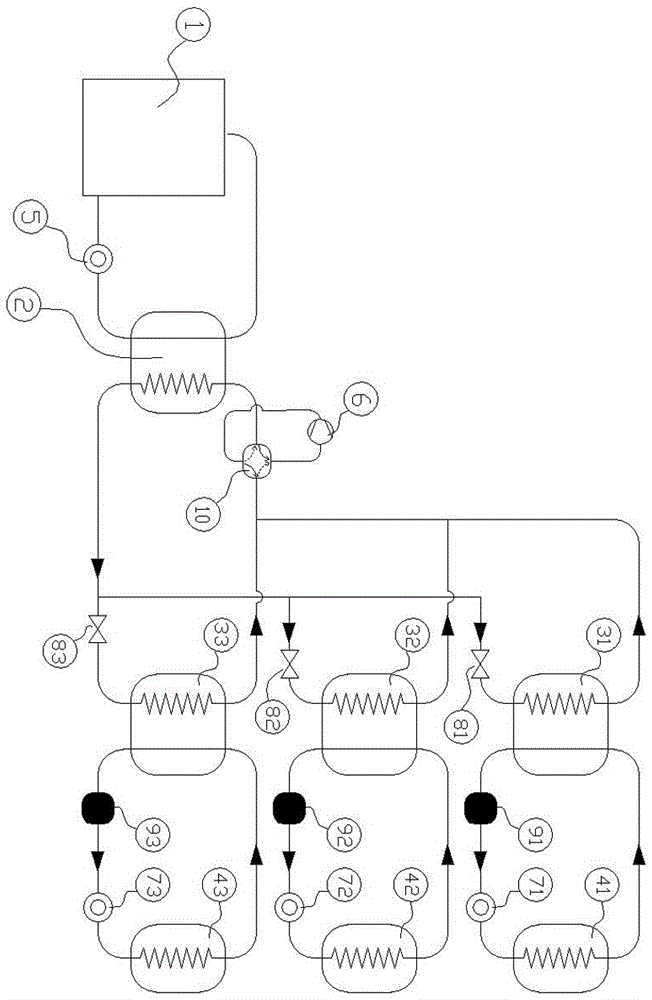

Image

Examples

Embodiment 1

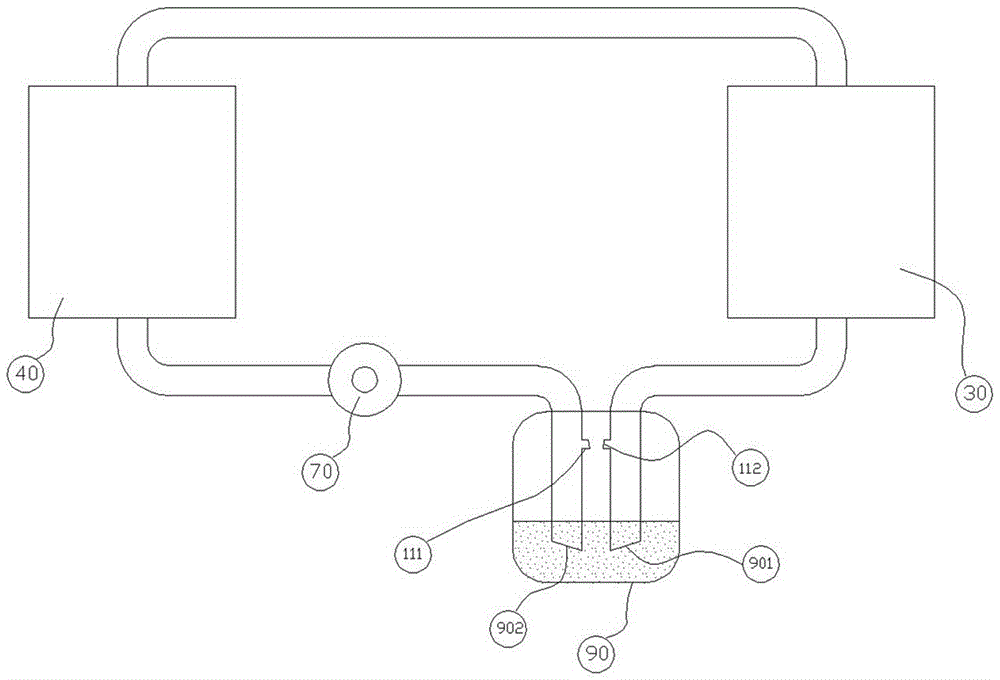

[0023] like image 3 The work flow chart of the first scheme of the power heat pipe circulation system of the present invention is shown, including the second heat exchanger (30), the indoor heat exchanger (40), the first air return hole (111), the second air return hole (112), and the circulation pump (70) and the liquid storage tank (90). When the power heat pipe circulation system works in refrigeration mode, the circulation pump (70) draws a large amount of liquid refrigerant from the liquid storage tank (90) and the part that passes through the air return hole one (111) Supplement a small amount of gaseous refrigerant that is stable throughout the cycle and send it to the indoor heat exchanger (40). The indoor heat exchanger (40) is in contact with the high-temperature heat source, and the liquid working medium is heated by the high-temperature heat source in the indoor heat exchanger (40). Evaporate into gas and absorb heat, the gas formed by evaporation and part of the ...

Embodiment 2

[0025] like Figure 4The work flow diagram of the second scheme of the power heat pipe circulation system of the present invention is shown, including heat exchanger 2 (30), indoor heat exchanger (40), liquid return device (12), circulation pump (70), liquid storage tank (90) and two one-way valves (131, 132), the air inlet of the indoor heat exchanger (40) is connected to the liquid storage tank (90), and the two interfaces (903) are located in the liquid storage tank (90) The upper part of the liquid surface of the working medium, the gas outlet of the second exchanger (30) is connected to the liquid storage tank (90), and the interface (904) of the two is located at the upper part of the liquid surface of the working medium in the liquid storage tank (90); the liquid return device The liquid inlet end of (12) is connected to the liquid storage tank (90), and the two interfaces (905) are located at the lower part of the liquid surface of the working medium in the liquid stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com