Wide-range electric pressure debugging meter

A debugger and wide-range technology, applied in the field of debuggers, can solve the problems of inconvenient operation, difficult to control, cumbersome disassembly and assembly, etc., and achieve the effect of being convenient to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

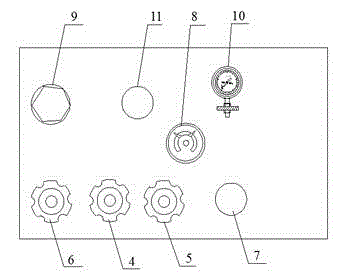

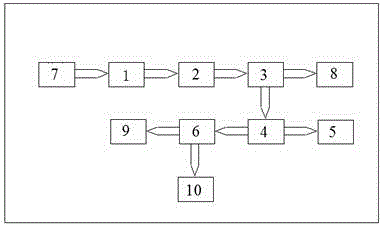

[0016] Such as figure 1 , 2 As shown, the pressure adjustment instrument includes a motor 1, an oil pump piston 2 and a booster cylinder 3 installed in the box, and also includes a control valve 4, a pressure reducing valve 5, a fine-tuning valve 6, a power switch 7, and a pressure regulator installed on the surface of the box. Electric contact pressure gauge 8, standard gauge output interface 9, adjusted meter output interface 10 and oil filling port 11, power switch 7 is connected to motor 1, motor 1 is connected to oil pump piston 2, oil pump piston 2 is connected to oil filling port 11 and booster cylinder 3, The booster cylinder 3 is connected to the electric contact pressure gauge 8 and the control valve 4, the control valve 4 is connected to the pressure reducing valve 5 and the fine-tuning valve 6, and the fine-tuning valve 6 is connected to the output port 9 of the standard meter and the output port 10 of the adjusted meter, forming a pressure adjustment instrument as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com