Secondary resistance detection circuit of ignition coil

A secondary resistance and ignition coil technology, applied in the direction of measuring resistance/reactance/impedance, measuring devices, measuring electrical variables, etc., can solve problems affecting production efficiency, visual fatigue, etc., reduce human errors, improve production efficiency, method simple and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

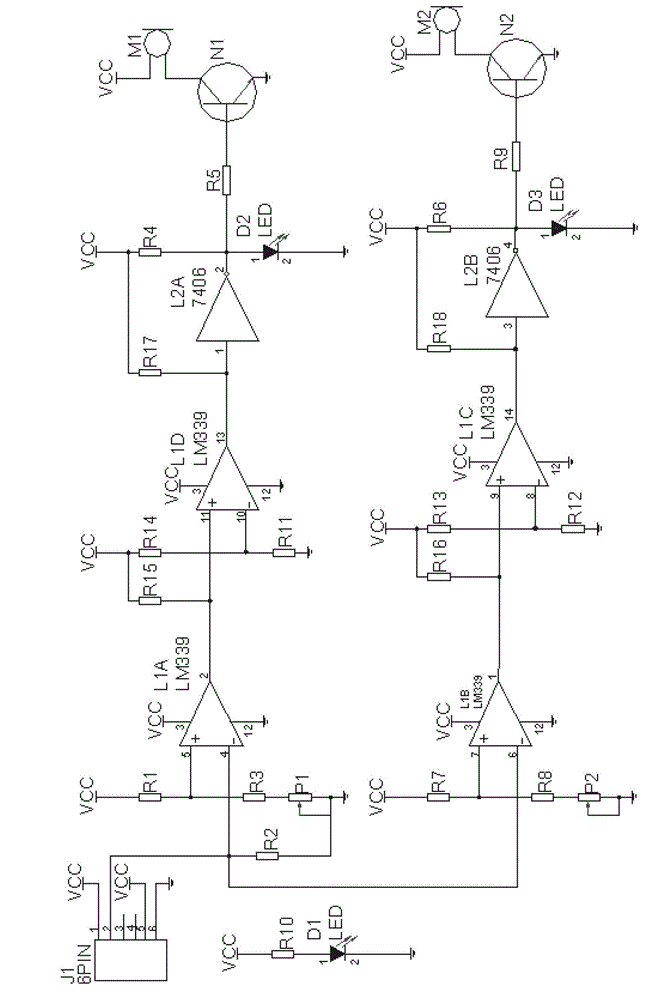

[0017] The ignition coil secondary resistance detection circuit provided by the present invention will be described in detail below with reference to the drawings and specific embodiments.

[0018] Such as figure 1 As shown, the ignition coil secondary resistance detection circuit provided by the present invention includes: terminal J1, operational amplifier, inverter, transistors N1, N2, light-emitting diodes D1, D2, D3, resistors R1-R18, adjustable resistors P1, P2, buzzer M1, M2; where:

[0019] Terminal J1 is an input terminal, and its terminals 1 and 2 are test input terminals, which are connected to the secondary side of the ignition coil under test during detection; terminals 1 and 5 of terminal J1 are connected to the power supply VCC, and terminals 6 are connected to the ground wire ;

[0020] The operational amplifiers L1A, L1B, L1C, and L1D are four operational amplifiers in the same package, among which: the non-inverting input terminal 5 of the operational ampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com