Magnetic coupling gearbox

A variable speed, magnetic technology, applied in the direction of electromechanical device, control mechanical energy, electromechanical transmission device, etc., can solve the problem of mechanical transmission device not being targeted, affecting the service life of other parts, poor safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

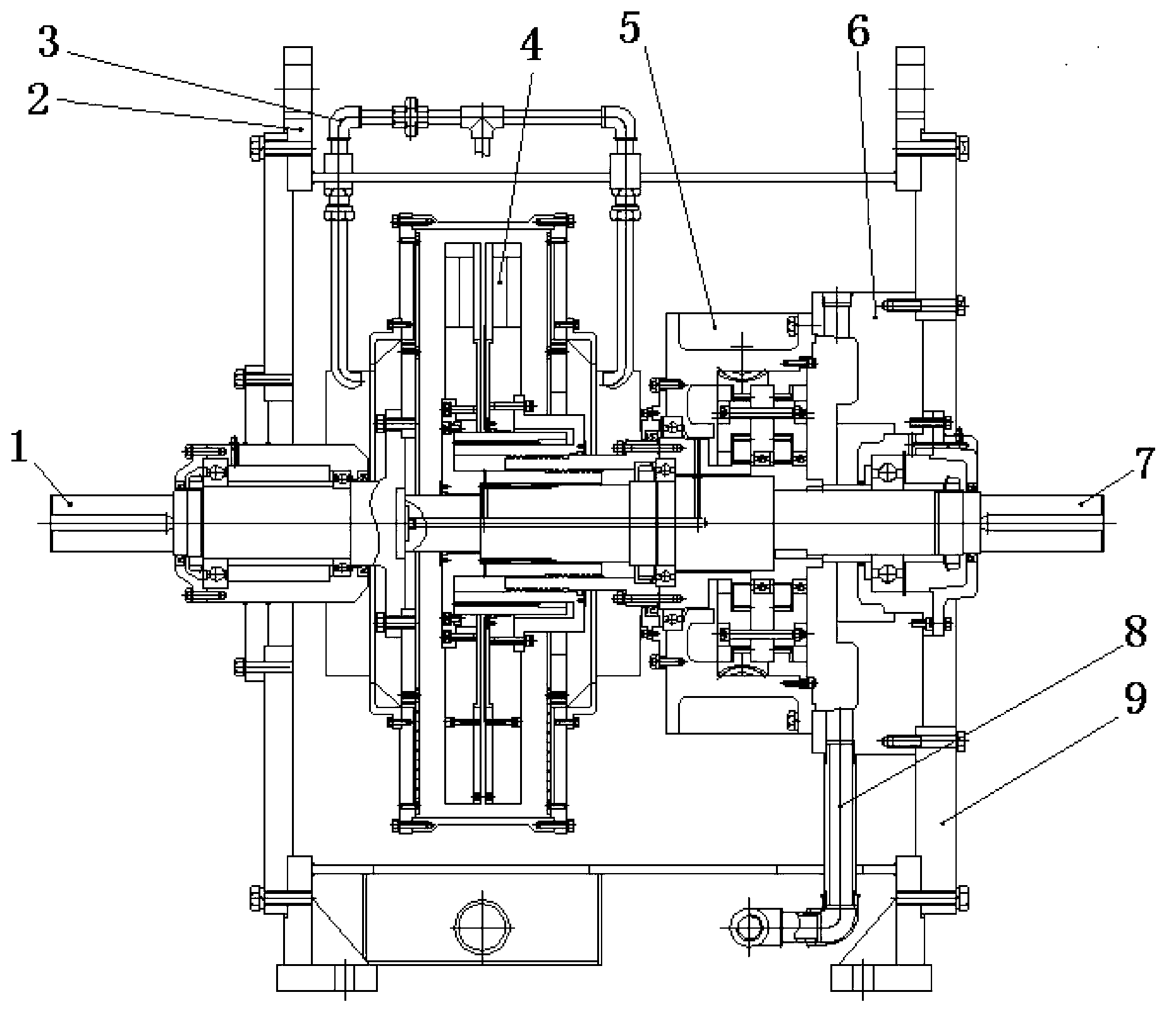

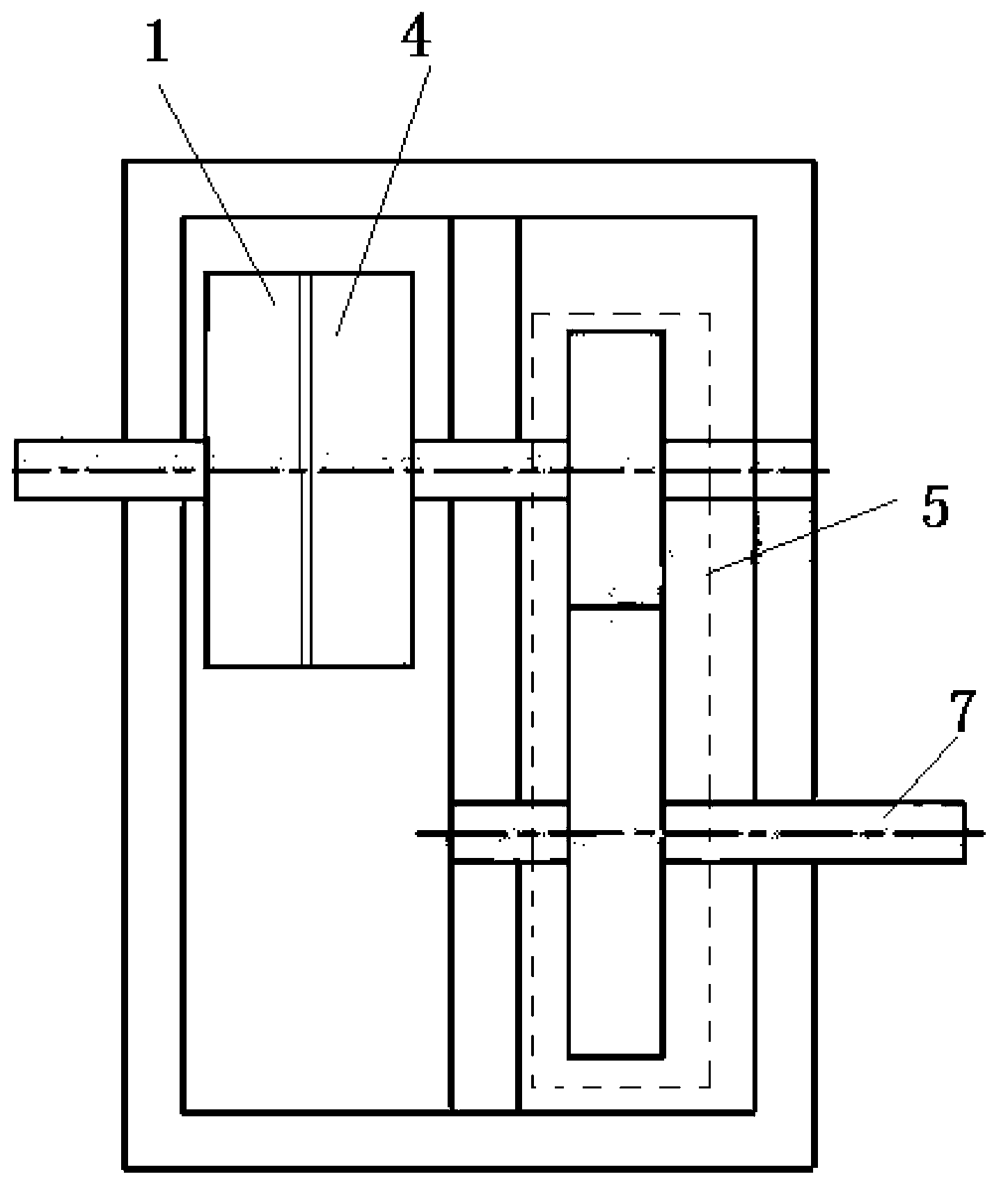

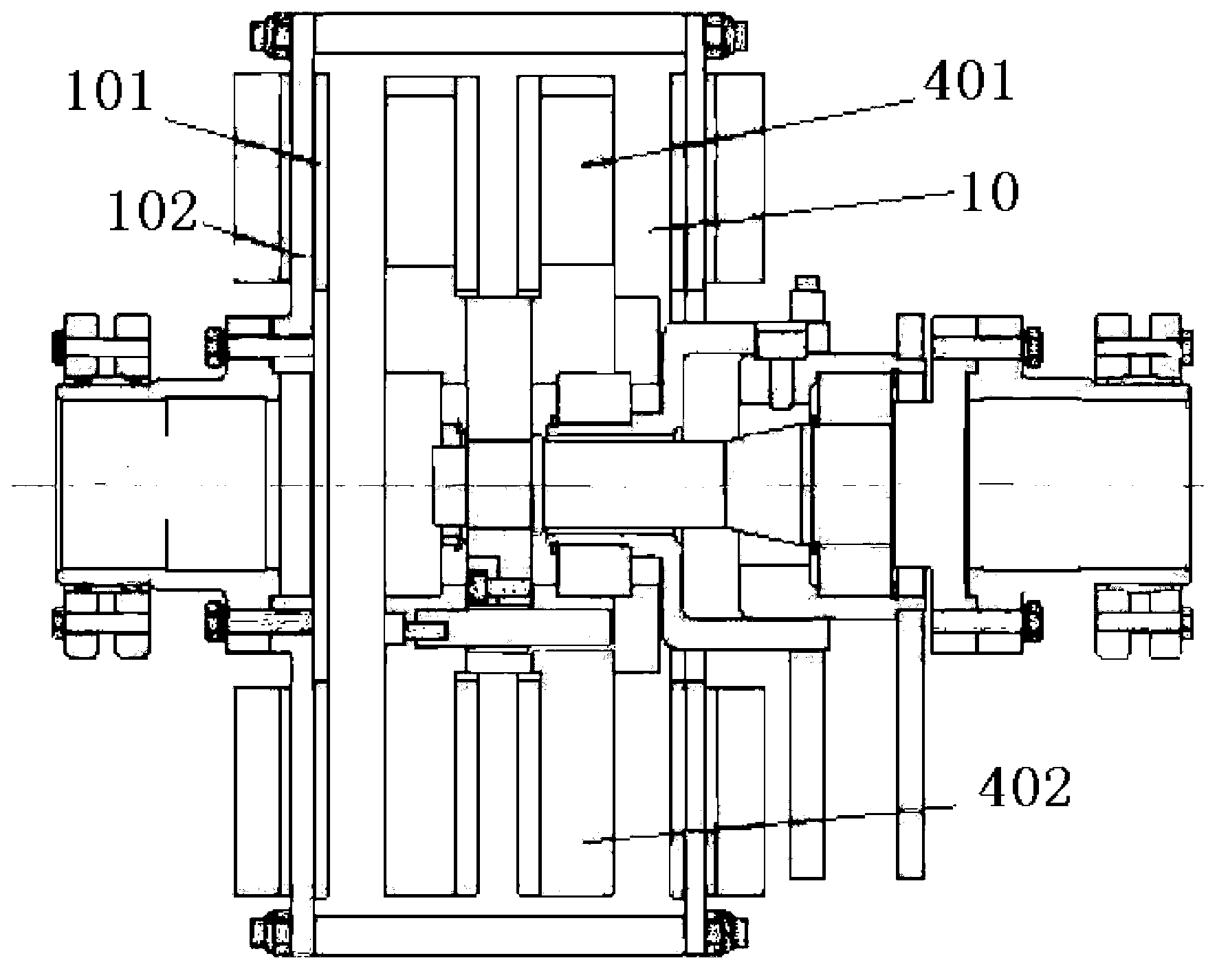

[0026] This embodiment provides a magnetic coupling speed changer, which is characterized in that: the magnetic coupling speed changer includes an input assembly speed regulating gear system 1 speed regulating gear system, a box body speed regulating gear system 2 speed regulating gear systems, an oil and water circuit System Flying Gear System 3 Flying Gear System, Output Assembly Flying Gear System 4 Flying Gear System, Flying Gear System Flying Gear System 5 Flying Gear System, Flying Gear System Base Flying Gear System 6 Flying Gear System, output shaft speed regulating gear system 7 speed regulating gear systems, oil return pipe speed regulating gear system 8 speed regulating gear systems, output flange speed regulating gear system 9 speed regulating gear systems;

[0027] The input assembly speed control gear system 1 speed control gear system and the output assembly speed control gear system 4 speed control gear system are magnetically coupled, and there is an adjustable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com