Shrimp flavor essence for frozen conditioning foods and preparation method thereof

A technology of frozen conditioning and food, applied in the field of shrimp flavor essence and its preparation, shrimp flavor essence for frozen conditioning food and its preparation, to achieve the effect of good seafood flavor, mellow flavor, and quick heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

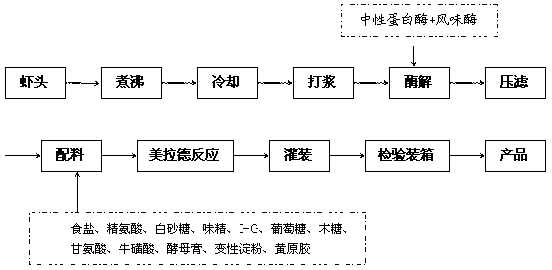

Method used

Image

Examples

Embodiment 1

[0022] A shrimp flavor essence for frozen prepared food, which consists of the following components:

[0023] Shrimp head enzymatic solution 100 parts; salt is 4.0% of the weight of the shrimp head enzymatic solution, arginine is 0.2% of the weight of the shrimp head enzymatic solution, white sugar is 1.0% of the weight of the shrimp head enzymatic solution, monosodium glutamate is shrimp 1.0% of the weight of the head enzymatic solution, I+G is 0.1% of the weight of the shrimp head enzymatic solution, glucose is 2.0% of the weight of the shrimp head enzymatic solution, xylose is 0.5% of the weight of the shrimp head enzymatic solution, glycine is 0.50% of the weight of the shrimp head enzymatic solution, taurine is 0.1% of the weight of the shrimp head enzymatic solution, yeast paste is 0.5% of the weight of the shrimp head enzymatic solution, modified starch is 3.0% of the weight of the shrimp head enzymatic solution, Xanthan gum is 0.05% of the weight of the shrimp head enz...

Embodiment 2

[0033] A shrimp flavor essence for frozen prepared food, which consists of the following components:

[0034] Shrimp head enzymatic solution 100 parts; salt is 6.0% of the weight of the shrimp head enzymatic solution, arginine is 0.22% of the weight of the shrimp head enzymatic solution, white sugar is 1.5% of the weight of the shrimp head enzymatic solution, monosodium glutamate is shrimp 1.5% of the weight of the head enzymatic solution, I+G is 0.2% of the weight of the shrimp head enzymatic solution, glucose is 3.0% of the weight of the shrimp head enzymatic solution, xylose is 0.8% of the weight of the shrimp head enzymatic solution, glycine is 0.80% of the weight of the shrimp head enzymatic solution, taurine is 0.15% of the weight of the shrimp head enzymatic solution, yeast paste is 0.8% of the weight of the shrimp head enzymatic solution, modified starch is 4.0% of the weight of the shrimp head enzymatic solution, Xanthan gum is 0.08% of the weight of the shrimp head e...

Embodiment 3

[0044] A shrimp flavor essence for frozen prepared food, which consists of the following components:

[0045]Shrimp head enzymatic solution 100 parts; salt is 8.0% of the weight of the shrimp head enzymatic solution, arginine is 0.25% of the weight of the shrimp head enzymatic solution, white sugar is 2.00% of the weight of the shrimp head enzymatic solution, monosodium glutamate is shrimp 2.0% of the weight of the shrimp head enzymatic solution, I+G is 0.30% of the weight of the shrimp head enzymatic solution, glucose is 4.0% of the weight of the shrimp head enzymatic solution, xylose is 1.0% of the weight of the shrimp head enzymatic solution, glycine is 1.0% of the weight of the shrimp head enzymatic solution, taurine is 0.20% of the weight of the shrimp head enzymatic solution, yeast paste is 1.0% of the weight of the shrimp head enzymatic solution, modified starch is 6.0% of the weight of the shrimp head enzymatic solution, Xanthan gum is 0.1% of the weight of the shrimp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com