Device for dispersing nano material in scale via liquid state turbulent flow instant high-pressure cutting method

A technology of instantaneous high pressure and nanomaterials, applied in chemical instruments and methods, dissolution, mixers, etc., can solve the problems of high energy consumption, poor effect, and small output energy of ultrasonic technology, and achieve stable and reliable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

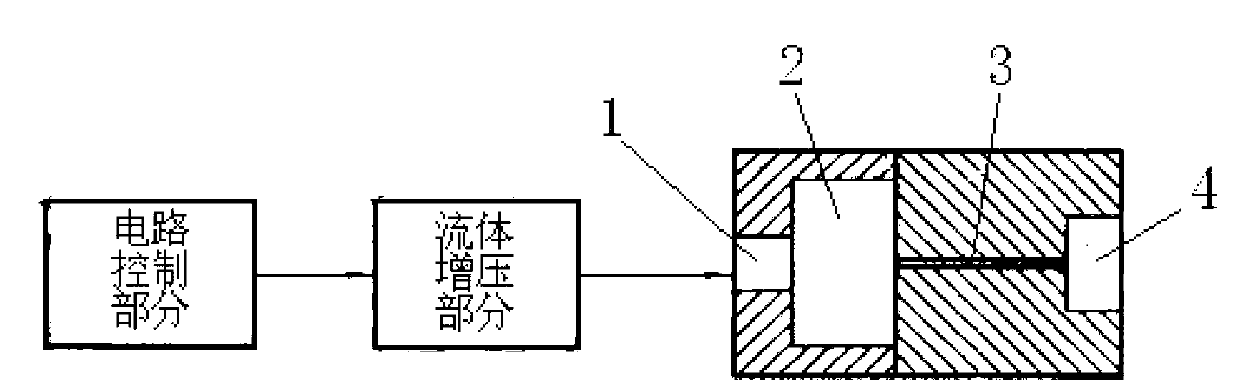

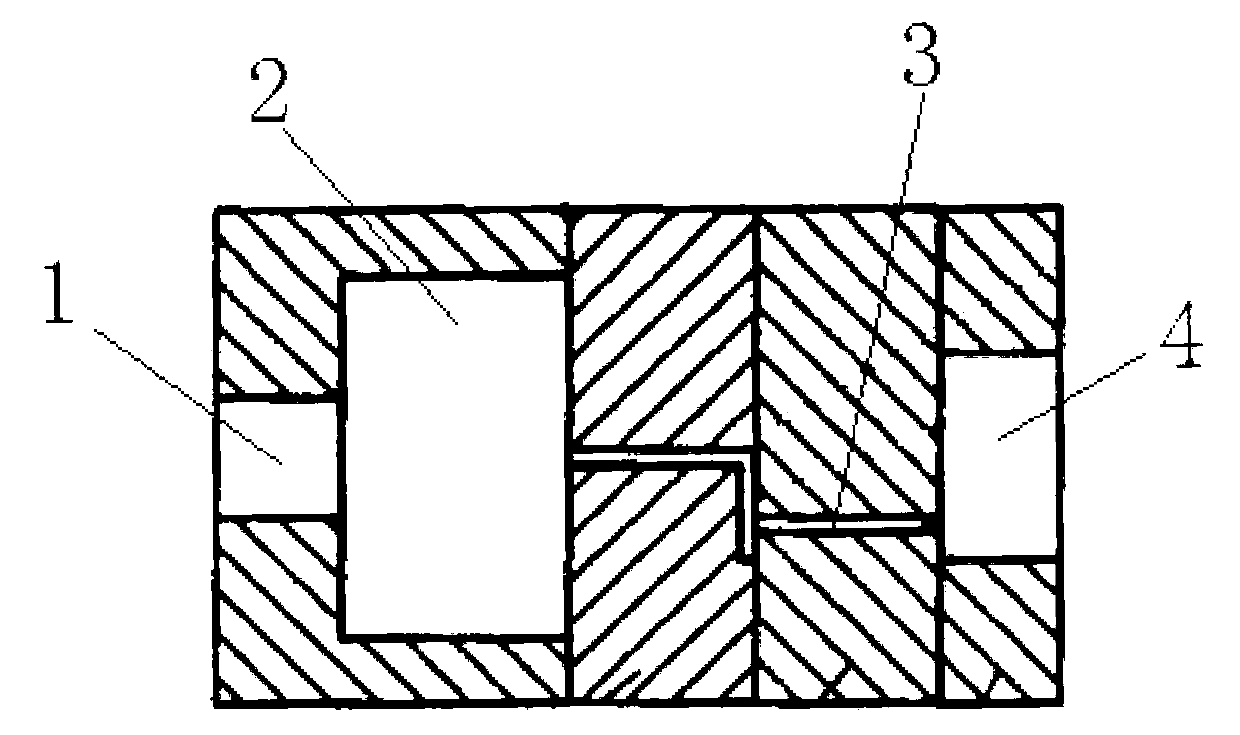

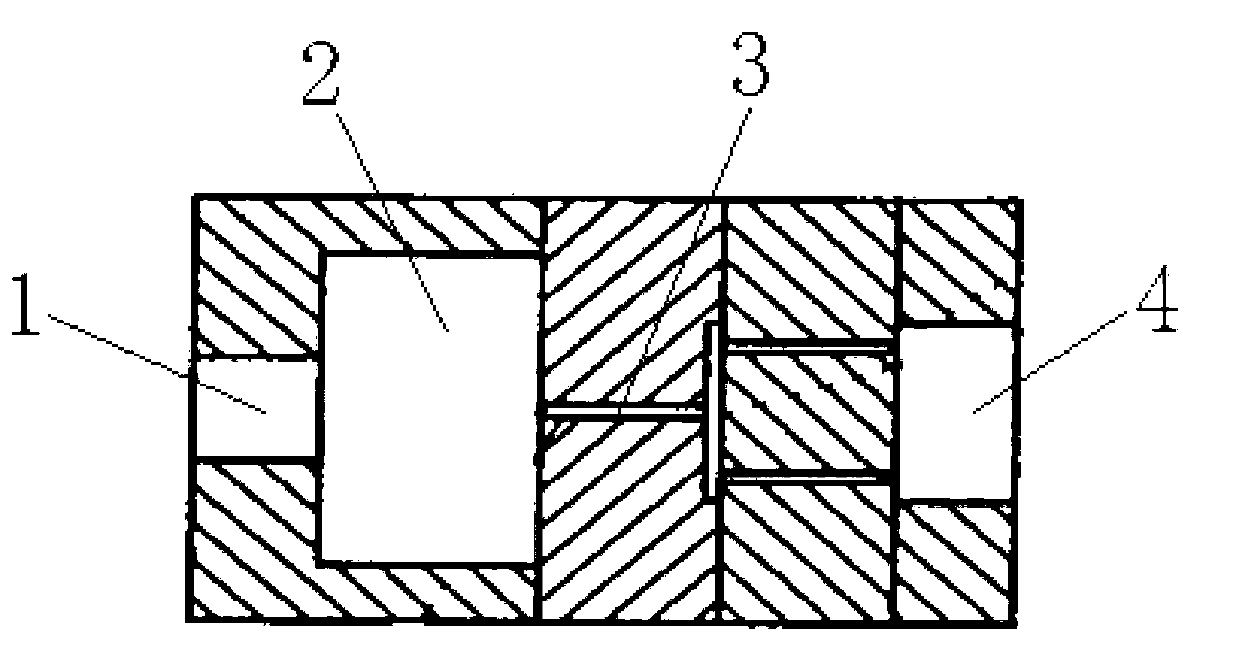

[0018] Such as Figure 1-Figure 4 shown. Liquid turbulent instantaneous high-pressure shearing method for large-scale dispersion of nanomaterials, including feed inlet 1, turbulent flow generation chamber 2, high-pressure turbulent flow groove 3, discharge outlet 4, feed inlet 1 front-end supply The fluid with the material to be processed enters, the end of the feed port 1 is connected to one side of the turbulent flow chamber 2, the front end of the high-pressure turbulent flow groove 3 is connected to the other side of the turbulent flow chamber 2, and the end of the high-pressure turbulent flow groove 3 is connected to the discharge port 4. The high-pressure turbulent flow dispersion chamber is composed of the feed inlet 1, the turbulence generating chamber 2, the high-pressure turbulent flow trough 3, and the discharge outlet 4, wherein the radial cross-sectional area of the feed inlet 1 is smaller than the radial cross-sectional area of the turbulent flow generating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com