Method for filling catalyst in tube type reactor

A technology of tube-and-tube reactors and catalysts, which is applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as uneven loading of catalysts, achieve good loading effects, uniform loading, and reduce the difficulty of loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

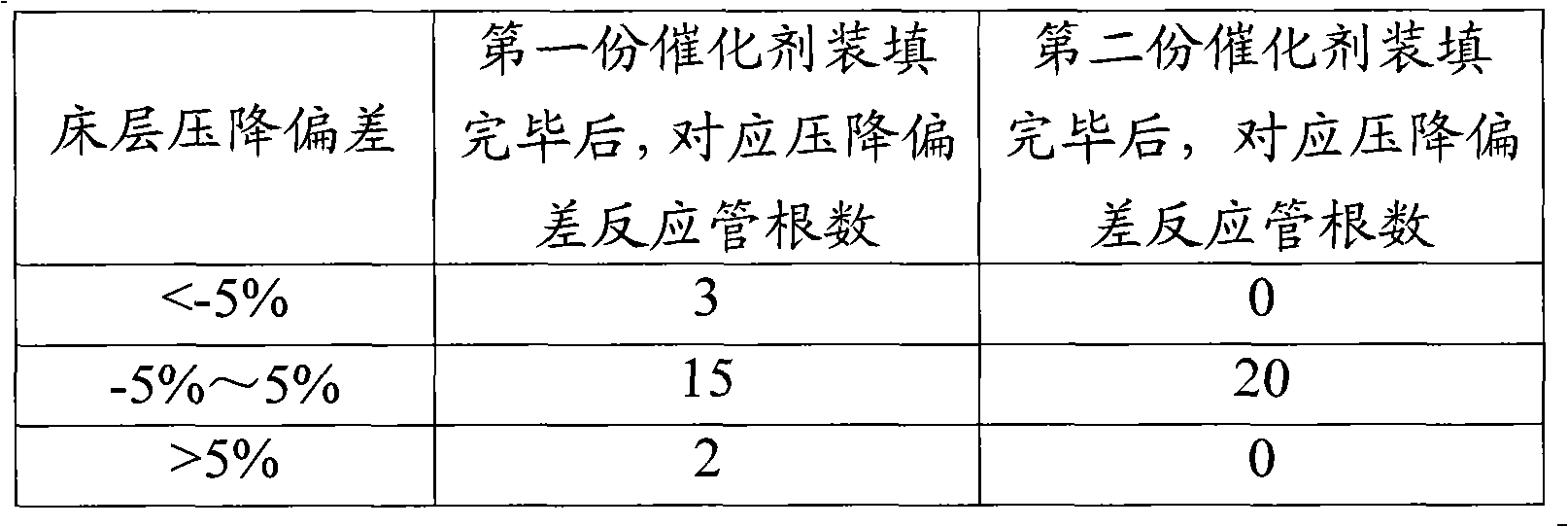

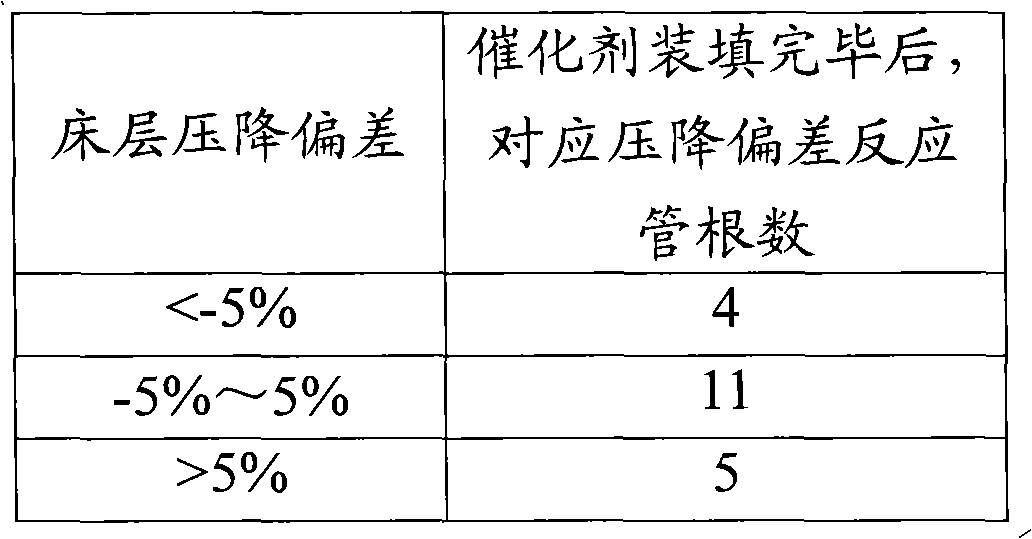

[0031] Take 20 aforementioned glass tubes and place them vertically, install a plugging spring at the bottom of each glass tube, and fill the upper part of the plugging spring with 100 mm high Φ3 mm ceramic balls to avoid catalyst leakage during the filling process. According to calculation, the amount of catalyst loaded theoretically in each glass tube is 4kg, and according to the method of the present invention, 20 parts of 2kg catalysts are prepared in total. Load the first part of catalyst evenly into each glass tube, and control the rising speed of the catalyst bed height to 25mm / s (v1). See Table 1 for deviation statistics.

[0032] It can be seen that there are two glass tubes with a pressure drop higher than 5% of the average pressure drop; three glass tubes with a pressure drop lower than 5% of the average pressure drop. Carry out the loading of the second part of catalyst according to the method of the present invention: the glass tube with pressure drop lower than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com