Combined three-roller continuous rolling mill

A three-roll rolling mill and combined technology, applied in the direction of metal rolling, etc., can solve the problems of cumbersome processing procedures, affecting the quality of rolling precision pipes, and low roll pass accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

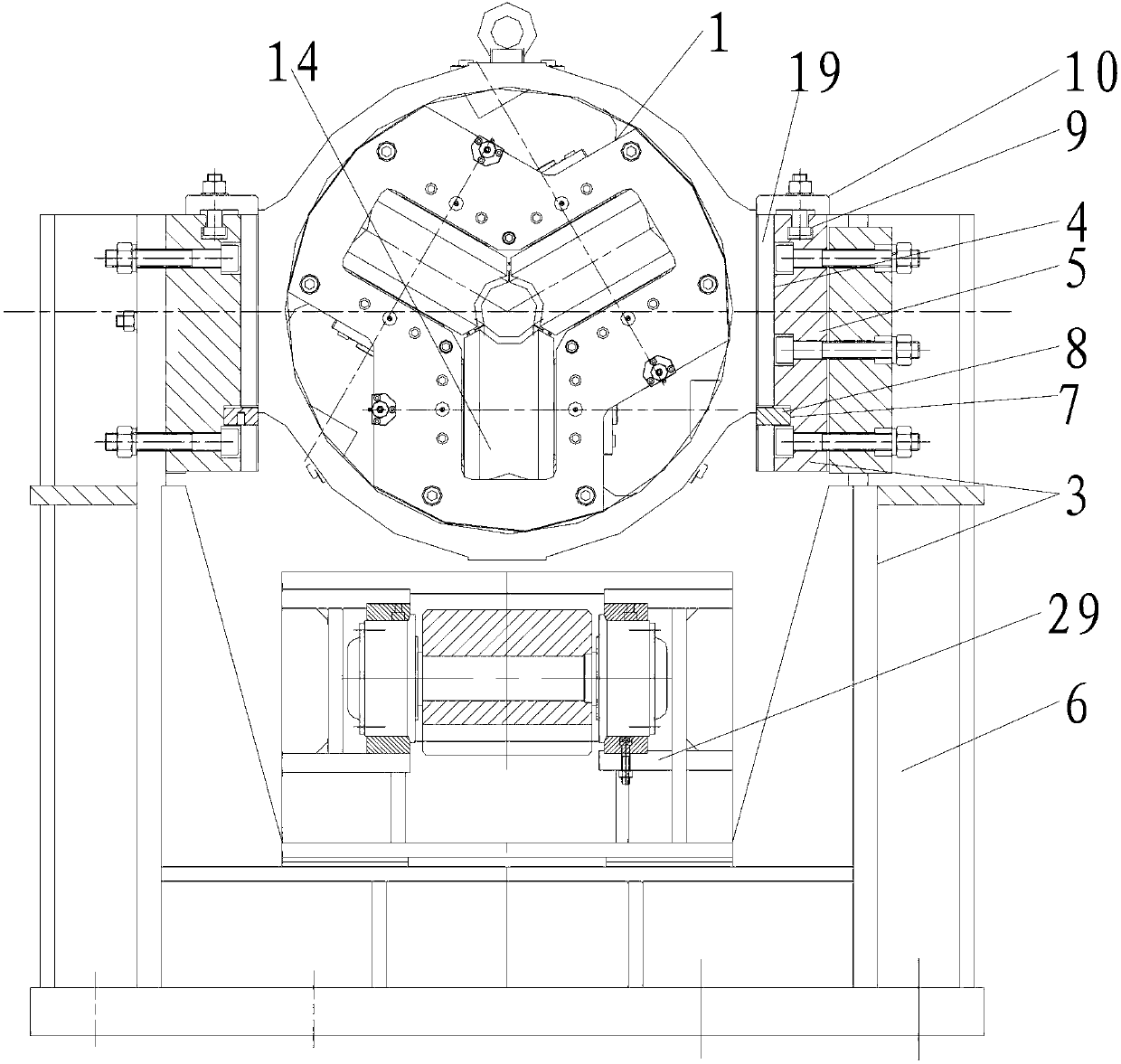

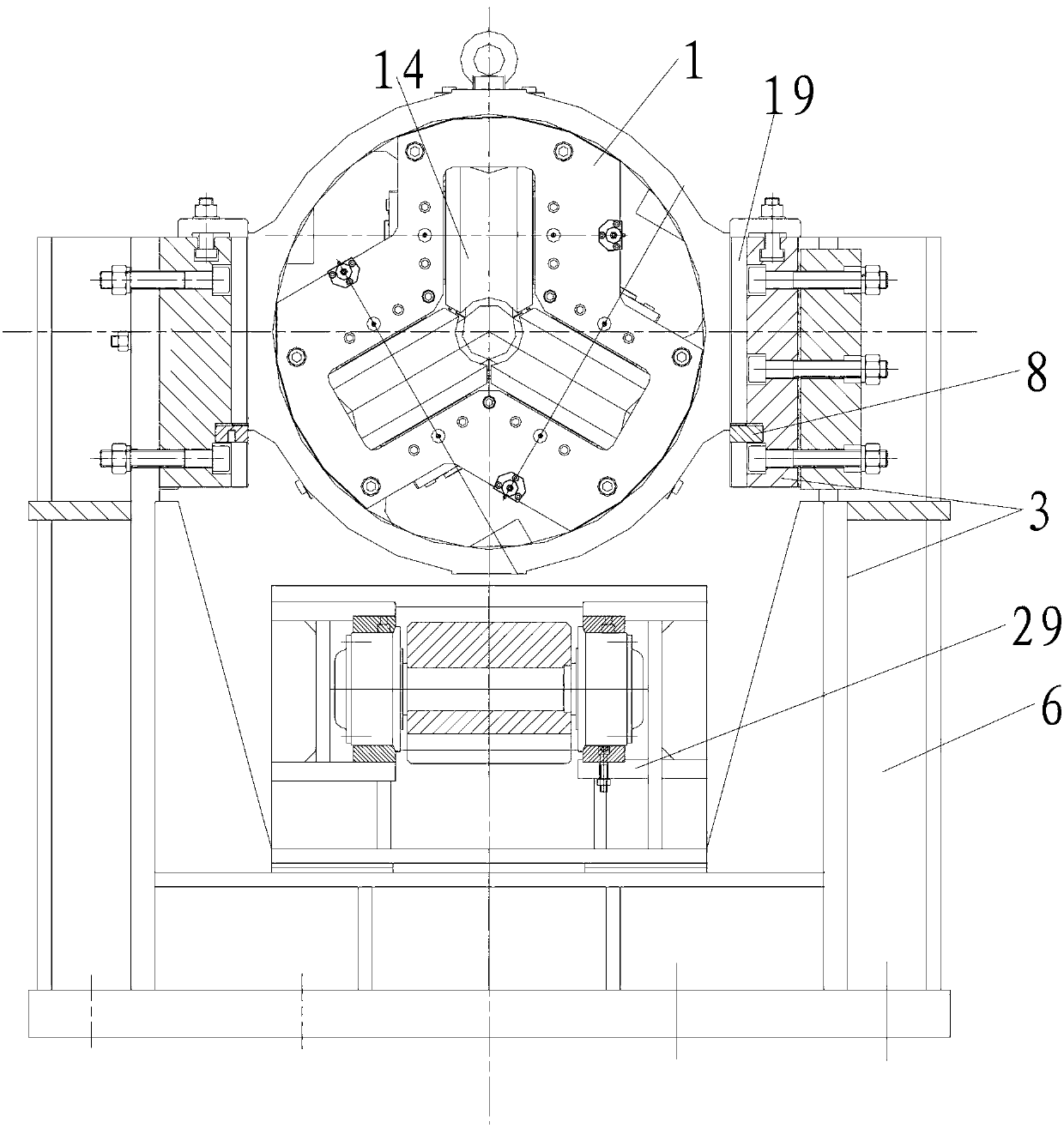

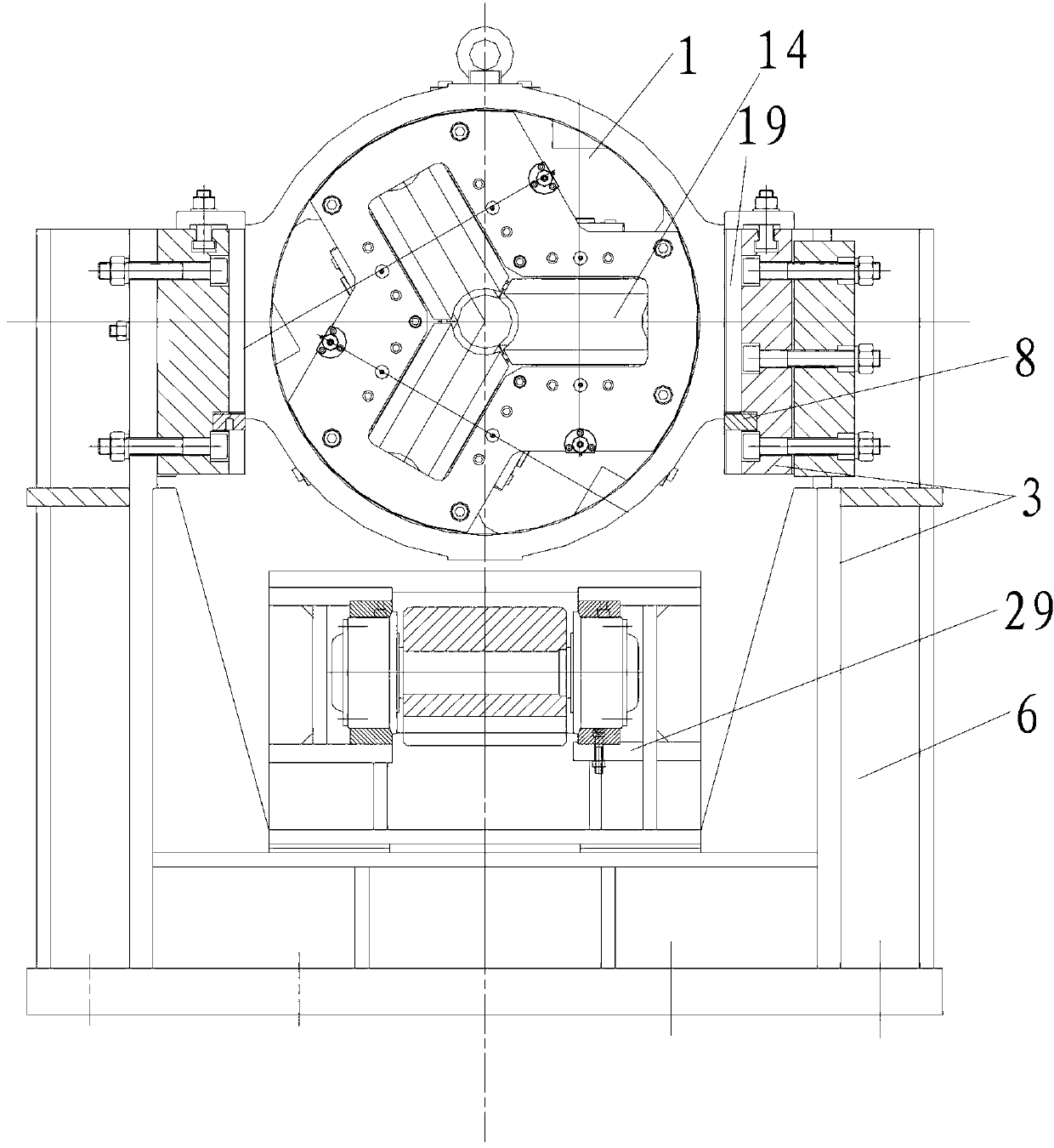

[0033] The combined three-roll continuous rolling mill (or pipe jacking machine) according to the embodiment of the present invention includes: a plurality of roll cores 1 alternately arranged at intervals in turn, and each roll core 1 is installed on the side plate 5, and every few stands three The side plates of the rolling mill are installed on a core frame 3, such as Figure 1 to Figure 4 As shown, each core frame 3 has a base 6, and the side plates 5 of all three-roll rolling mills are connected or integrally arranged on multiple bases 6, and the left and right sides of the roll core 1 are symmetrically arranged There is a convex block 19 , and a guide rail 8 supporting the convex block 19 is arranged in the side plate 5 , and the bottom surface of the convex block 19 is supported on the guide rail 8 . Figure 1 to Figure 4 The main difference between the three-roll mills in the three-roll mill is that the shape or direction of the roll arrangement of the three-roll mill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com