Swing type diameter changing mechanism of spring machine

A spring machine and swing type technology, which is applied in the field of spring winding machinery, can solve the problems that the precision and stability of the spring cannot be properly guaranteed, it is difficult to effectively control the quality of the spring, and the rigidity and stability of the winding mechanism can be reduced. , to achieve the effect of convenient adjustment, good overall rigidity and high degree of intelligent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

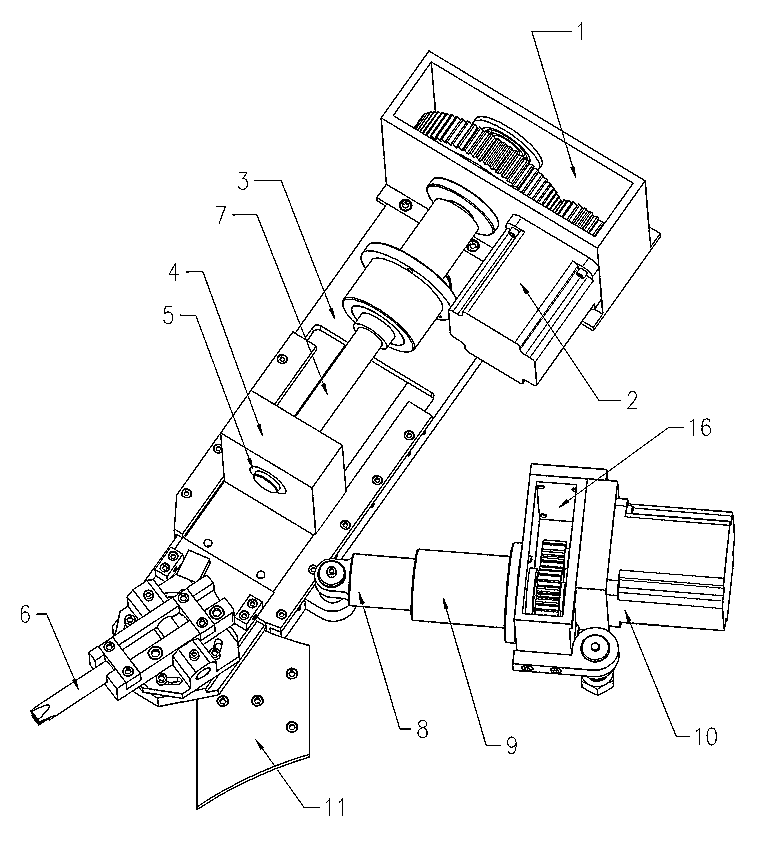

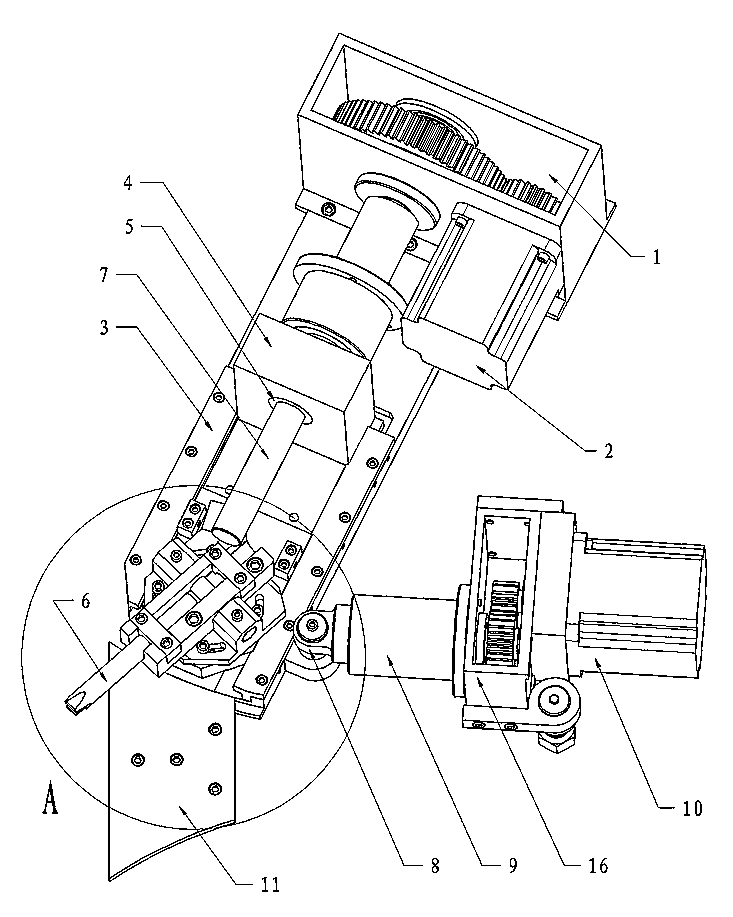

[0026] The swing reducing mechanism of the spring machine is as follows: figure 1 - Figure 6 As shown, it includes a slide-type ejector rod swing device and a connecting rod telescopic swing device; each set of devices has a pin shaft connected to the front wall of the spring machine under the base, and can rotate and swing around the respective pin shafts;

[0027] The slide plate type ejector rod swing device includes a slide seat 3, a slide plate 4, and a motor Ⅰ connected to the reduction box 1. The slide plate 4 is fixed with the ejector rod 6 and the screw nut 5, and the slide seat 3 is fixed on the output shaft of the reduction box 1. The screw Ⅰ is fixed, and the screw Ⅰ and the screw nut 5 are screwed together. When the screw Ⅰ rotates, it can drive the screw nut 5 and the slide plate 4 together with the ejector rod 6 to advance and retreat together;

[0028] The motor II connected to the reduction box II is fixed on the base of the connecting rod telescopic swing d...

Embodiment 2

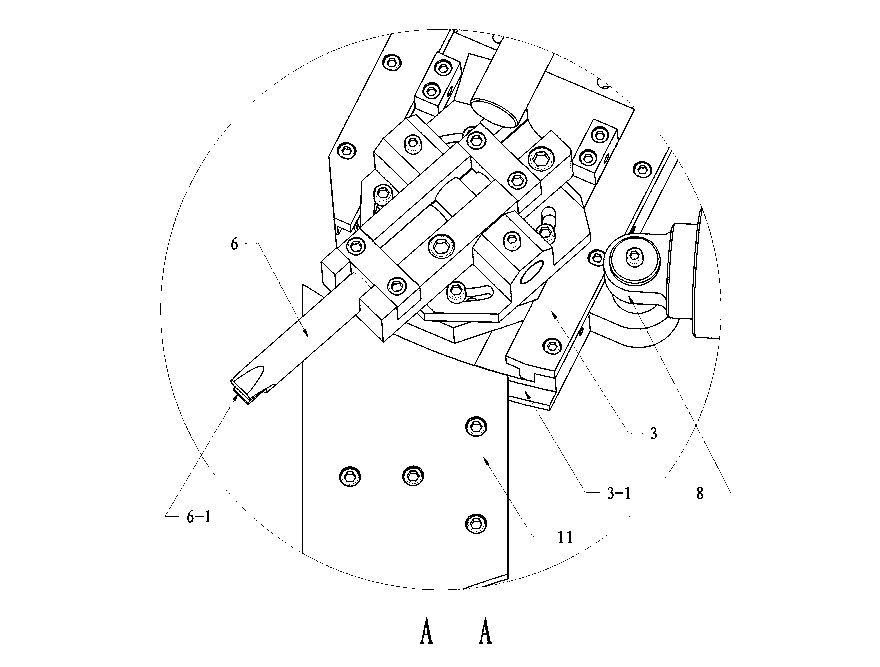

[0031] Embodiment 2, the basic structure movement mode is the same as that of Embodiment 1, the only difference is that an arc-shaped sliding tenon concentric with the axis line of the sliding seat pin shaft 15 is set at the front end of the sliding seat 3 of the sliding plate type ejector rod swing device 3-1, the pressing plate 11 adapted to the arc-shaped sliding tenon 3-1 is fixed on the front wall of the spring machine, such as image 3 As shown, the swing trajectory of the slide-type ejector rod swing device is more accurate, and the stability and rigidity of the diameter-changing mechanism are significantly improved.

[0032] As a preferred solution, the swing-type reducing mechanism of the present invention can be arranged in an array on the front wallboard of the spring machine, and the push rods 6 on each set of swing-type reducing mechanism can be adjusted to different directions respectively to adapt to the multi-axis spring machine. Process requirements, depending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com