A kind of see-through film and its manufacturing method

A manufacturing method and technology of see-through film, applied in the field of see-through film, can solve the problems of high construction difficulty, increased difficulty in pasting and replacing pictures, rising product cost, etc., and achieve safe and convenient pasting and replacement, good ink absorption and color rendering, The effect of improving strength and support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

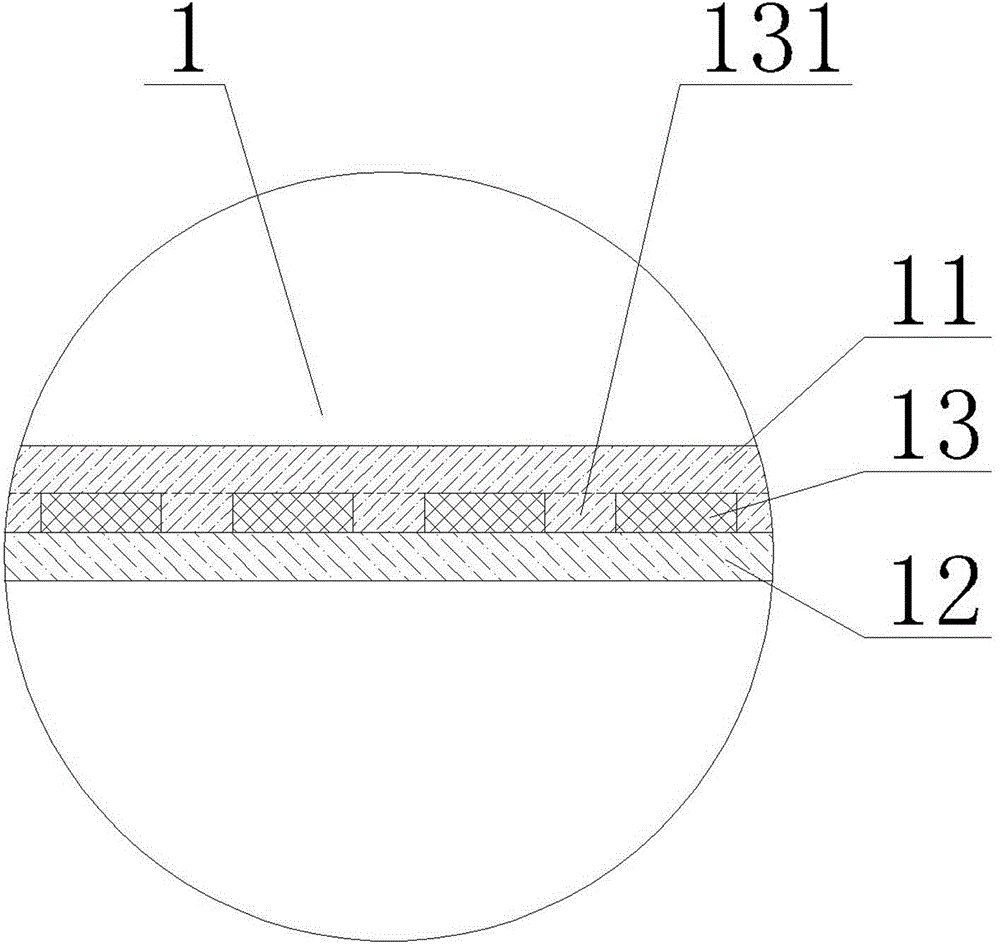

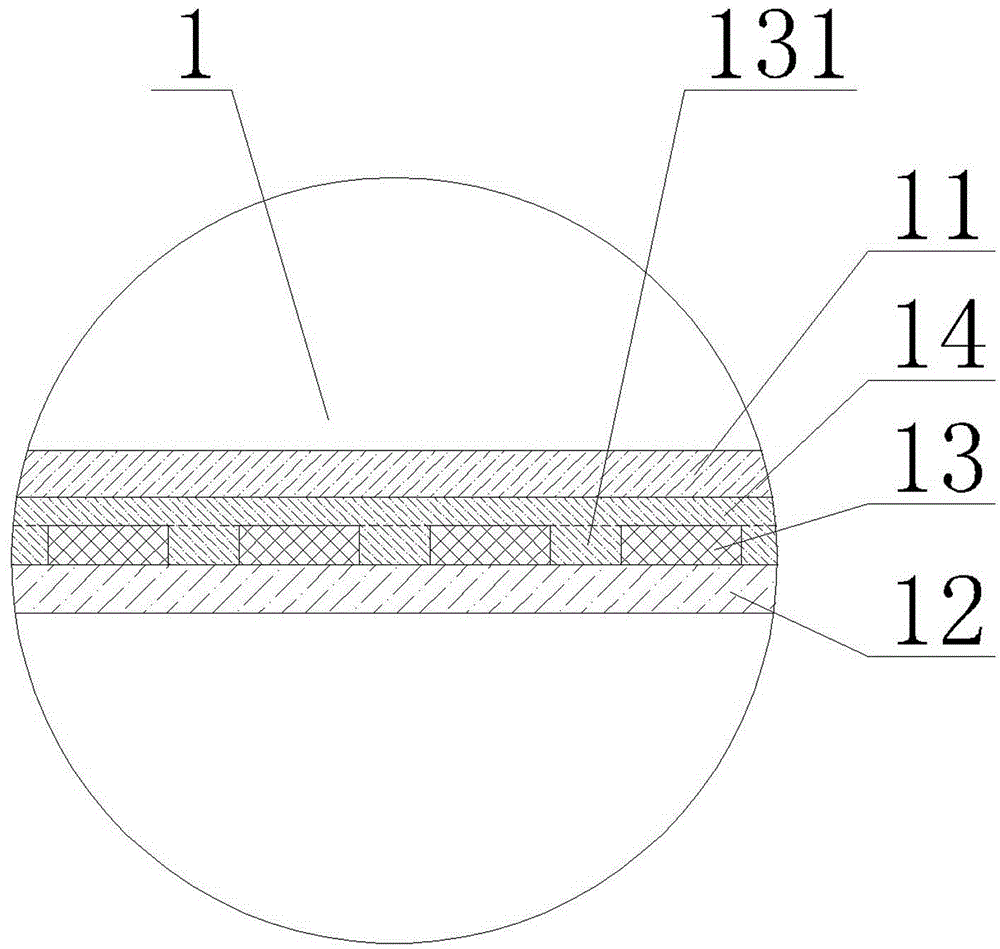

[0038] Such as Figure 1-Figure 10As shown, the internal see-through film of the present invention includes a see-through film body 1, and the see-through film body 1 includes a self-adhesive transparent plastic soft film 11 capable of absorbing ink and preventing the self-adhesive transparent plastic soft film capable of absorbing ink from 11 is a shaped transparent plastic film 12 that is stretched and deformed, and a color-developing printing layer 13 is arranged between the shaping transparent plastic film 12 and the ink-absorbing self-adhesive transparent plastic film 11, and the color-developing printing layer 13 is distributed with The light-transmitting area 131, wherein the ink-absorbing self-adhesive transparent plastic soft film 11 faces away from the color-developing printing layer 13 and the surface of the light-transmitting area 131 is the printing ink-absorbing surface and the sticking surface, and the shaped transparent plastic film 12 faces away from the color-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com