Charging device for thermal transfer printer

A technology of feeding device and thermal transfer printing machine, which is applied in the direction of rotary printing machine, printing machine, transfer printing, etc., can solve the problems that the production equipment cannot meet the experimental operation requirements, and it is difficult to ensure the accuracy of the action, so as to improve the Use safety, improve functionality, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below in conjunction with the drawings.

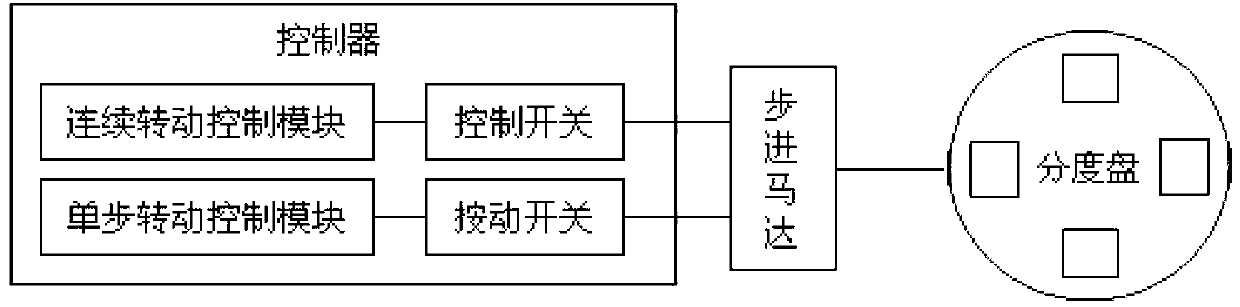

[0013] Such as figure 1 Shown is a feeding device of a thermal transfer machine, including an index plate, a stepping motor, and a controller. The index plate is provided with four material tables, and the four material tables are The rotating shaft is arranged in an array at 90° intervals. The stepping motor is used to drive the index plate to rotate; the controller is provided with a continuous rotation control module and a single-step rotation control module, and the continuous rotation control module passes The control switch controls the operation of the stepping motor. The single-step rotation control module controls the operation of the stepping motor by pressing the switch; the continuous rotation control module drives the indexing plate to perform continuous 90° rotations in the same direction through the stepping motor. In addition, there is a time gap between each 90° rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com